Preparation method of supported photocatalyst Bi2WO6-TiO2/foam metal

A technology of bi2wo6-tio2 and metal foam, which is applied in the field of water pollution treatment, can solve the problems of high desorption rate of photocatalyst powder and insufficient utilization of light energy, and achieve good photocatalytic activity, good visible light absorption and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

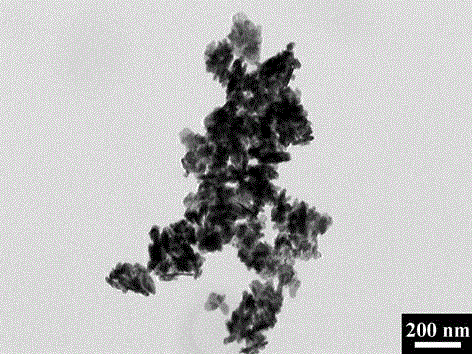

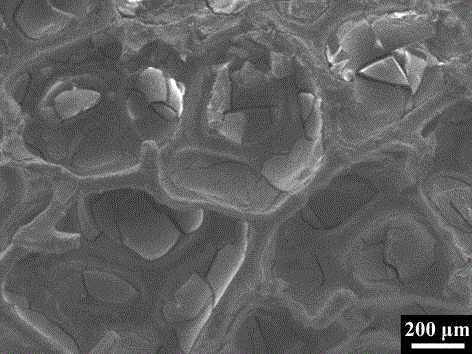

[0027] Bi(NO 3 ) 3 ·5H 2 O and ethylene glycol were mixed and stirred for 1h as a Bi source, and then absolute ethanol was added as a mixed solvent. According to the molar ratio of Bi and Ti atoms being 3:1, a certain amount of TiO 2 Powder, mixed well, hydrothermal reaction at 180°C for 15 hours, washed and dried; then take a certain amount of Bi 2 WO 6 -TiO 2 precursor, and dispersed in anhydrous ethanol solution, fully stirred evenly. Take a certain quality of foamed nickel carrier, soak and wash it with acetone, dilute hydrochloric acid and deionized water to remove oil and oxides on the surface, then spray a layer of silica sol with a solid content of 25% on the surface, and dry it horizontally for 20 minutes , will Bi 2 WO 6 -TiO 2 The precursor dispersion was evenly sprayed onto the nickel foam carrier coated with silica sol coating, and after being dried horizontally for 20 min, it was calcined at 400 °C for 2 h to obtain supported Bi with visible light activit...

Embodiment 2

[0029] Bi(NO 3 ) 3 ·5H 2 O and ethylene glycol were mixed and stirred for 1h as a Bi source, and then absolute ethanol was added as a mixed solvent. According to the molar ratio of Bi and Ti atoms being 3:1, a certain amount of TiO 2 Powder, mixed well, hydrothermal reaction at 180°C for 15 hours, washed and dried; then take a certain amount of Bi 2 WO 6 -TiO 2 precursor, and dispersed in anhydrous ethanol solution, fully stirred evenly. Take a certain quality of foamed copper carrier, soak and wash it with acetone, dilute hydrochloric acid and deionized water to remove oil and oxides on the surface, then spray a layer of silica sol with a solid content of 25% on the surface, and dry it horizontally for 20 minutes , will Bi 2 WO 6 -TiO 2 The precursor dispersion was evenly sprayed onto the copper foam carrier coated with silica sol, and after being dried horizontally for 20 min, it was calcined at 400 °C for 2 h to obtain supported Bi with visible light activity. 2 WO...

Embodiment 3

[0031] Bi(NO 3 ) 3 ·5H 2 O and ethylene glycol were mixed and stirred for 1h as a Bi source, then absolute ethanol was added as a mixed solvent, and a certain amount of TiO was added according to the molar ratio of Bi and Ti atoms being 2:1. 2 Powder, mixed well, hydrothermal reaction at 180°C for 15 hours, washed and dried; then take a certain amount of Bi 2 WO 6 -TiO 2 precursor, and dispersed in anhydrous ethanol solution, fully stirred evenly. Take a certain quality of foamed copper carrier, soak and wash it with acetone, dilute hydrochloric acid and deionized water to remove the oil stains and oxides on the surface, then spray two layers of silica sol with a solid content of 25% on the surface, and dry it horizontally for 20 minutes , will Bi 2 WO 6 -TiO 2 The precursor dispersion was evenly sprayed onto the copper foam carrier coated with silica sol, and after being dried horizontally for 20 min, it was calcined at 400 °C for 2 h to obtain supported Bi with visib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com