Treatment method for waste water containing fluorine

A treatment method and technology for wastewater, which are applied in energy wastewater treatment, water/sludge/sewage treatment, ion-exchanged water/sewage treatment, etc., can solve the problems of complex resin loading modification process, difficult industrial application, poor adsorption effect, etc. , to achieve the effect of closed loop treatment, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

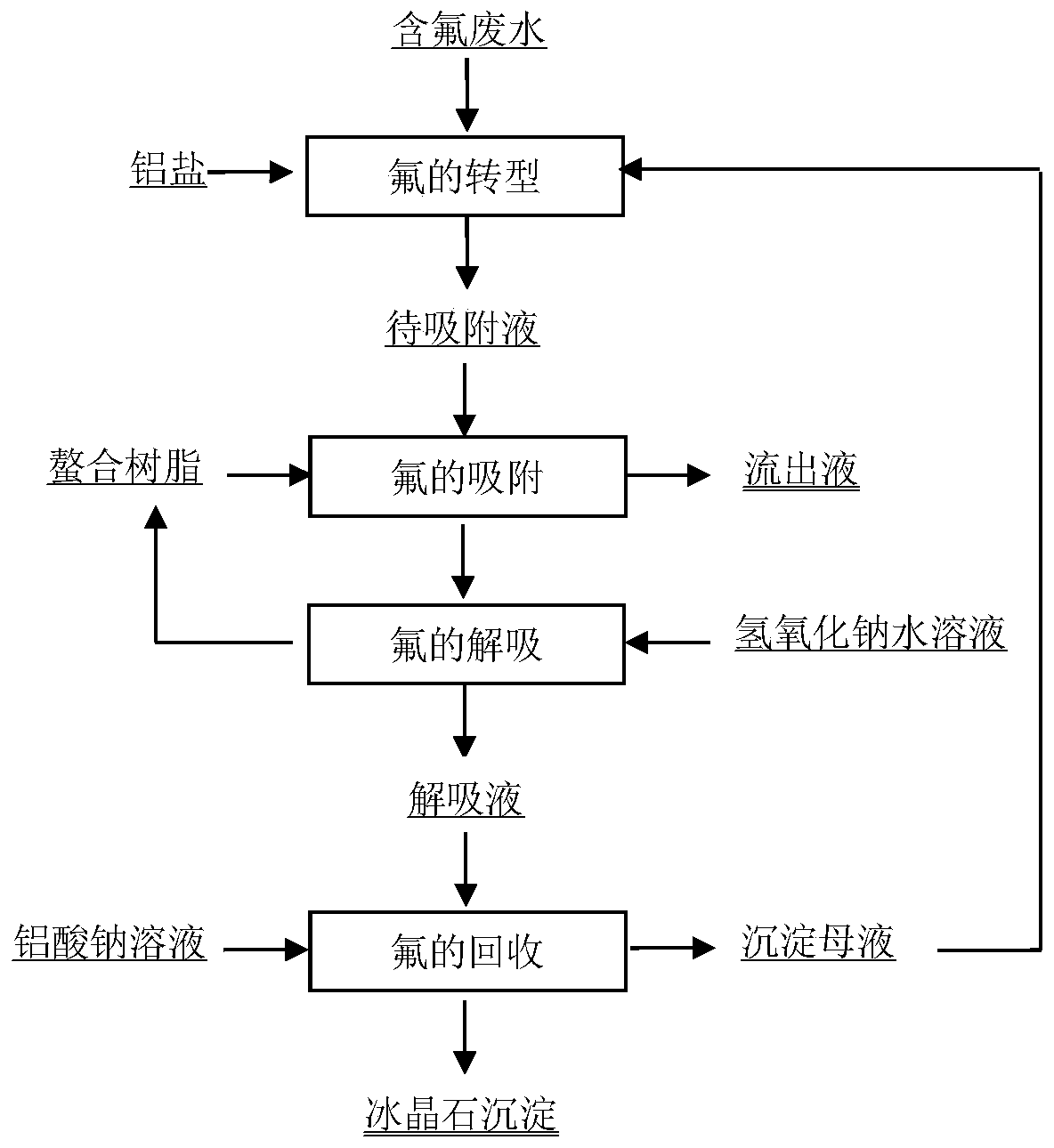

[0063] according to figure 1 The process flow chart shown is for the treatment of fluorine-containing wastewater, figure 1 It is the flow chart of the fluorine-containing wastewater treatment process provided by the embodiment of the present invention, and the specific treatment steps include:

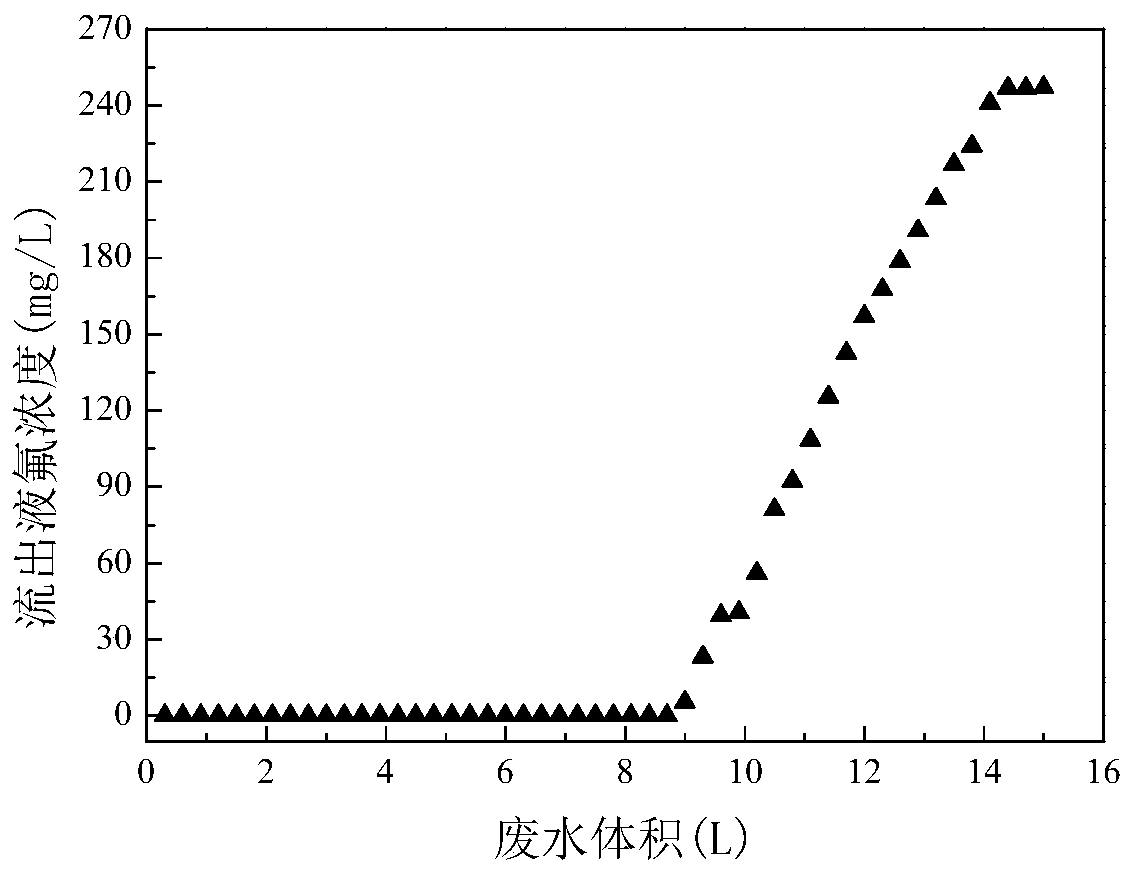

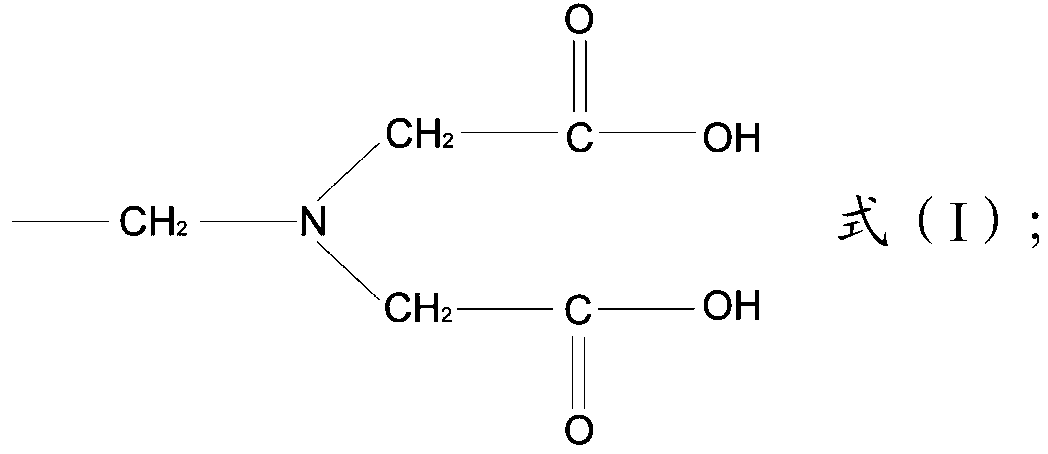

[0064] Add 17.5g of AlCl to 10L of fluorine-containing wastewater (fluoride ion concentration 250mg / L, pH value 5.0) 3 , and stirred and mixed for 10 minutes to obtain 10L of the liquid to be adsorbed. The chelating resin (n=1000) of 40g formula (i) structure is loaded into ion-exchange column, the liquid to be adsorbed is passed through the exchange column with a flow rate of 5mL / min, the residence time of the liquid to be adsorbed in the exchange column is 10min, outflow curve as figure 2 as shown, figure 2 is the adsorption outflow curve of Example 1 of the present invention.

[0065] After the resin is adsorbed and saturated, add a sodium hydroxide solution with a concentrat...

Embodiment 2

[0068] The difference with Example 1 is that what is loaded into the ion exchange column in Example 2 is the chelating resin (m=1200) of the structure of formula (ii). The experimental results show that when the concentration of fluoride ion in the effluent is breakthrough (that is, the concentration of fluoride ion is higher than 6 mg / L), the adsorption capacity of chelating resin to fluorine can reach 45.8 mg / g (dry resin).

Embodiment 3

[0070] The difference from Example 1 is that AlCl is added to 10L of fluorine-containing wastewater 3 The mass of the solution is 2.9g. During the adsorption step, the adsorbed liquid passes through the exchange column at a flow rate of 1mL / min; during the desorption step, the concentration of sodium hydroxide solution passes through the exchange column at a flow rate of 0.5mL / min. Experimental results show that the adsorption capacity of chelating resin to fluorine can reach 54.8 mg / g (dry resin).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com