Method for improving hydrogen storing property of AB2 type hydrogen storing alloy

A hydrogen storage alloy, AB2 technology, applied in the field of improving the hydrogen storage performance of AB2 type hydrogen storage alloy, can solve the problems of poor kinetic performance of hydrogen absorption and desorption, low discharge capacity, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

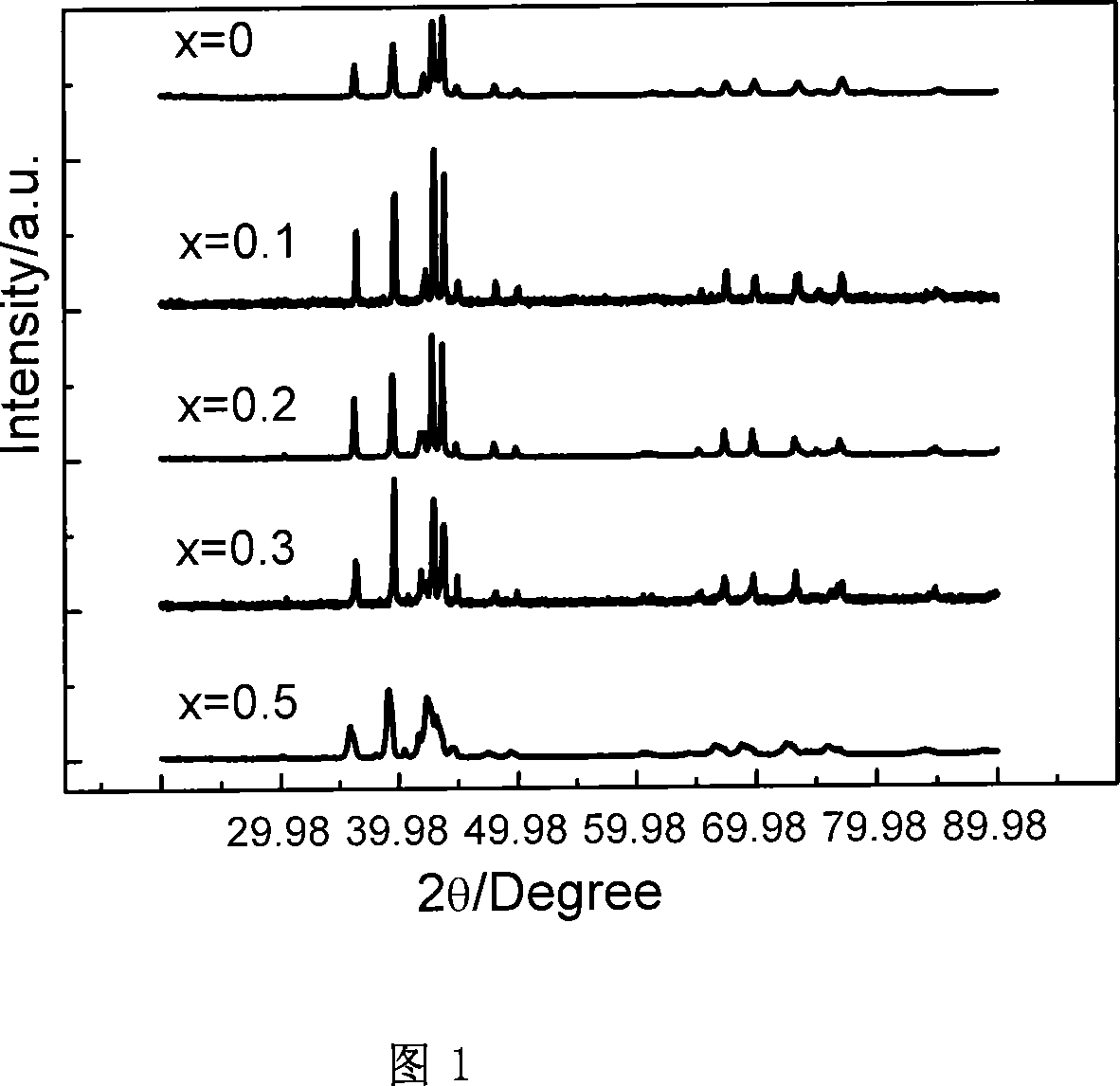

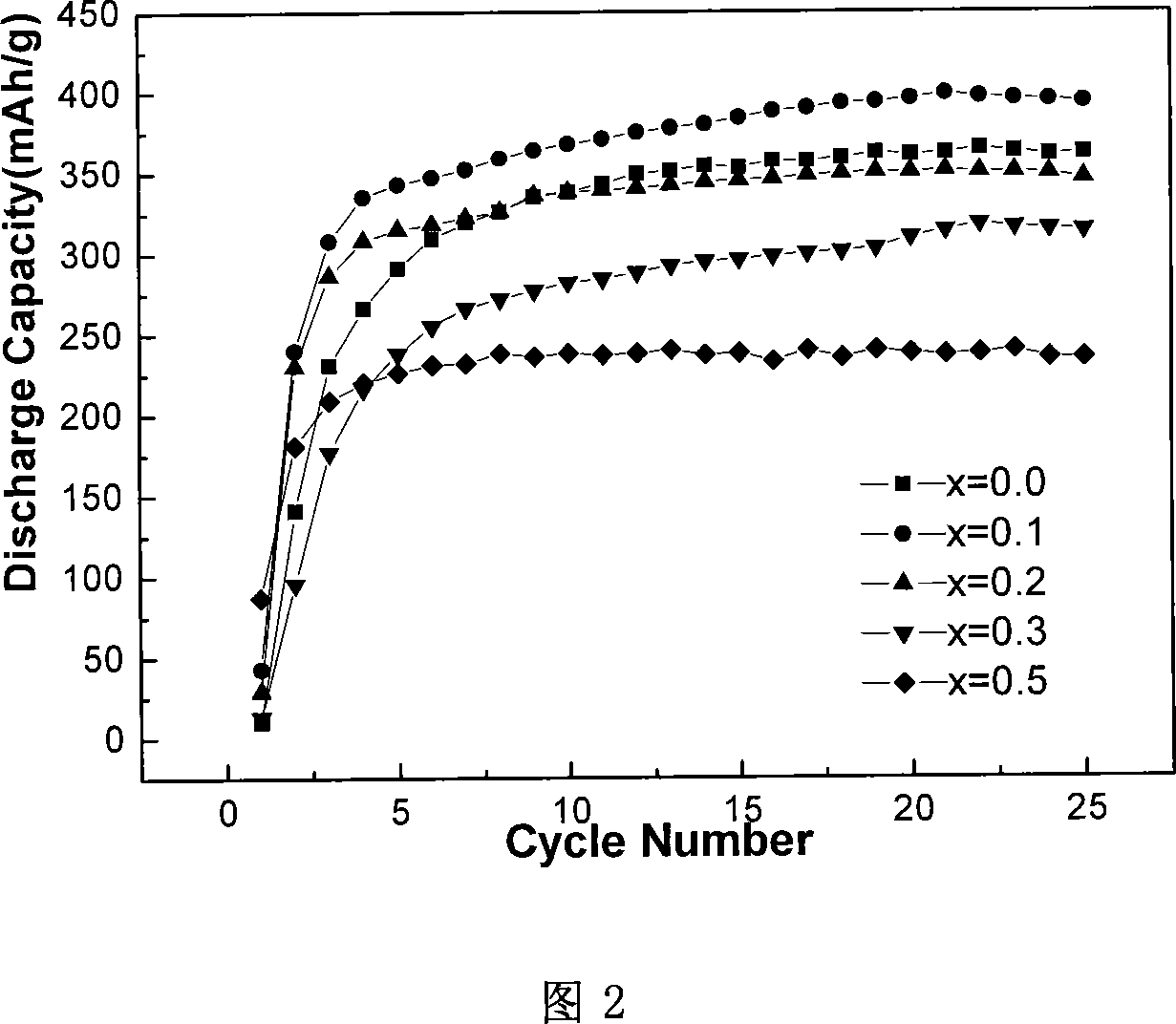

[0015] The design alloy composition is: (Ti 0.65 Zr 0.35 )(V 0.5 mn 0.3 Cr 0.4 Ni 0.8 ), the purity of the raw materials used in the experiment is more than 99.9%, and then the Nb powder with a purity of more than 99.9% is added to replace part V, and the proportioning becomes an alloy (Ti 0.65 Zr 0.35 )(V 0.5-x mn 0.3 Cr 0.4 Ni 0.8 )Nb x (X=0.1~0.5), using WK-II type non-consumable (tungsten electrode) vacuum electric arc furnace to melt the alloy. In order to ensure the composition and structure uniformity of the alloy ingot and inhibit segregation, the ingot was remelted four times. As shown in Figure 1 (Ti 0.65 Zr 0.35 )(V 0.5-x mn 0.3 Cr 0.4 Ni 0.8 )Nb x (X=0.1~0.5) The X-diffraction pattern of the hydrogen storage alloy shows that with the increase of the Nb content, the position of the diffraction peak of the main phase shifts slightly to the left (the direction of the decrease of the diffraction angle), which indicates that the unit cell of the main ph...

Embodiment 2

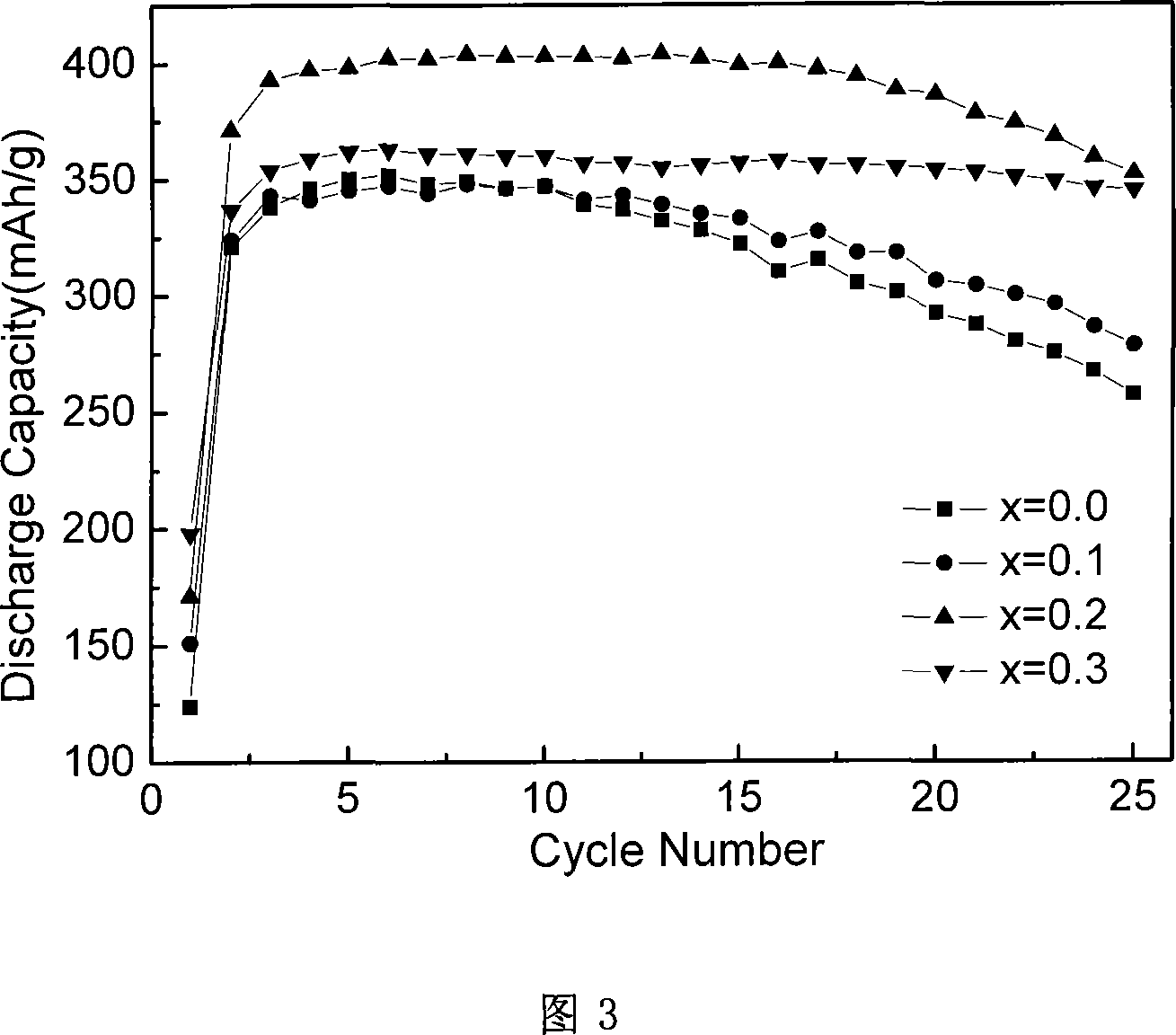

[0017] The design alloy composition is: TiZr 0.35 V 0.5 mn 0.3 Cr 0.4 Ni 0.8 , the purity of the raw materials used in the experiment is above 99.9%, and then Nb powder with a purity above 99.9% is added to replace part V, and the proportion becomes alloy TiZr 0.35 V 0.5-x mn 0.3 Cr 0.4 Ni 0.8 Nb x (X=0.1~0.3), using WK-II type non-consumable (tungsten electrode) vacuum electric arc furnace to melt the alloy. In order to ensure the composition and structure uniformity of the alloy ingot and suppress segregation, the ingot was remelted four times. TiZr 0.35 V 0.5-x mn 0.3 Cr 0.4 Ni 0.8 Nb x (X=0.1~0.3) The activation performance curve of the hydrogen storage alloy is shown in Figure 3. It can be seen from the figure that as the amount of Nb replacing V increases, the electrochemical capacity of the alloy first increases and then decreases. When x=0.2 , the discharge capacity of the alloy reaches a maximum value of 404mAh / g. The number of activations changed litt...

Embodiment 3

[0019] The design alloy composition is: TiMn 1.2 Cr 0.8 , the purity of the raw materials used in the experiment is above 99.9%, and then Nb powder with a purity above 99.9% is added to replace part of Cr, and the proportion becomes the alloy TiMn 1.2 Cr 0.8-x Nb x (X=0.1~0.5), using WK-II type non-consumable (tungsten electrode) vacuum electric arc furnace to melt the alloy. In order to ensure the composition and structure uniformity of the alloy ingot and inhibit segregation, the ingot was remelted four times. TiMn 1.2 Cr 0.8-x Nb x (X=0.1~0.5) The cycle stability curve of the hydrogen storage alloy is shown in Figure 4. It can be seen from the figure that as the amount of Nb replacing Cr increases, the electrochemical cycle stability of the alloy first increases and then decreases. When x When =0.1, the best cycle stability of the alloy is 92.55%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com