Aluminum and steel composite layer hydrogen storage tank and filament winding reinforced hydrogen storage bottle with aluminum and steel composite layer hydrogen storage tank as core

A technology of winding reinforcement and composite layers, which is applied in the direction of fixed-capacity gas storage tanks, the outer wall of the container structure, and the method of container discharge, etc., can solve the problems of hydrogen energy economic development obstacles, easy-to-destroy lattice structure, and small volume of 50 liters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

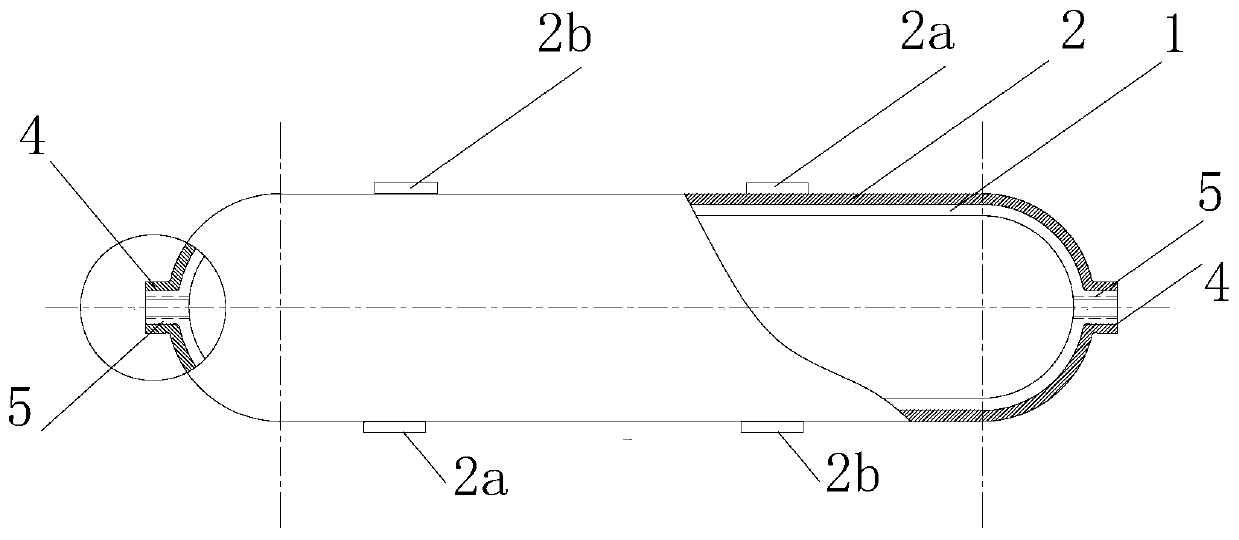

[0016] Implementation case 1, in the hydrogen storage tank of the present invention, a cylindrical aluminum alloy 1 with a certain wall thickness t1 is adopted. At the intersection of the spherical shell, there is a cylindrical pipe joint 4, which is integrated with the spherical shell through a sliding transition. The inner hole of the pipe joint 4 is processed with a standard internal thread 5, and the outer surface of the aluminum alloy inner layer is tightly and continuously covered with a The layer has a steel layer 2 with a thickness of t2, and the steel cladding layer 2 includes a cylindrical shape, a hemispherical shape, and a cylindrical shape at the pipe joint.

[0017] Further, in order to enhance the safe use and reliability of the hydrogen storage tank, and understand the parameter changes in the use of the hydrogen storage container, a patch pressure is provided on the outer surface of the aluminum and steel composite layer hydrogen storage tank (that is, the oute...

Embodiment example 2

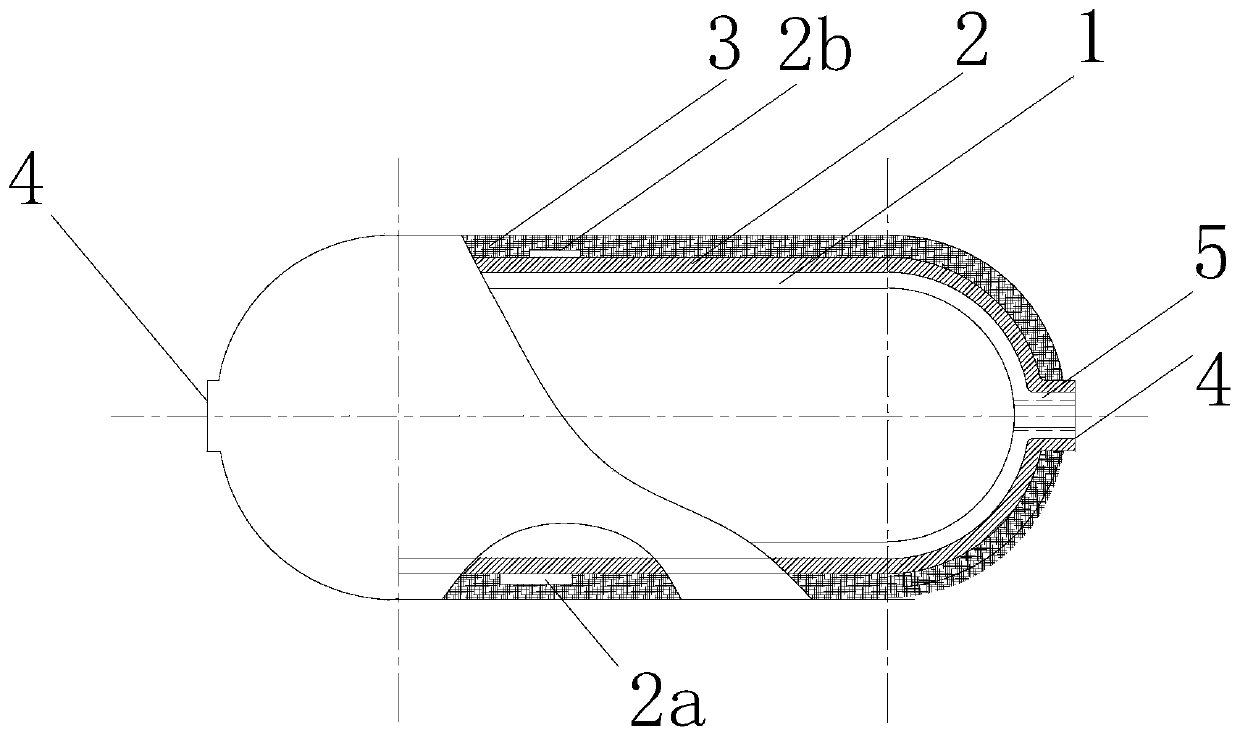

[0019] In the second implementation case, the "aluminum-steel composite layer hydrogen storage tank" produced in the first implementation case is used as the mandrel, and the reinforced composite material 3 composed of external fully wound fibers and resin is used, and the thickness of the 3 is t3.

[0020] Further, in order to enhance the safe use and reliability of the vehicle-mounted hydrogen storage tank and understand the parameter changes in the use of the hydrogen storage tank, a patch-type The pressure strain sensor 2a and the chip temperature sensor 2b, the electrical leads of the sensors 2a and 2b are drawn out of the winding layer 3 when the reinforced composite material layer 3 made of fiber and resin is wound.

[0021] The fibers in the reinforced composite material 3 made of above-mentioned fibers and resin adopt glass fiber, or aramid fiber, or carbon fiber, and the resin in the reinforced composite material 3 formed of the fiber and resin is epoxy resin or reinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com