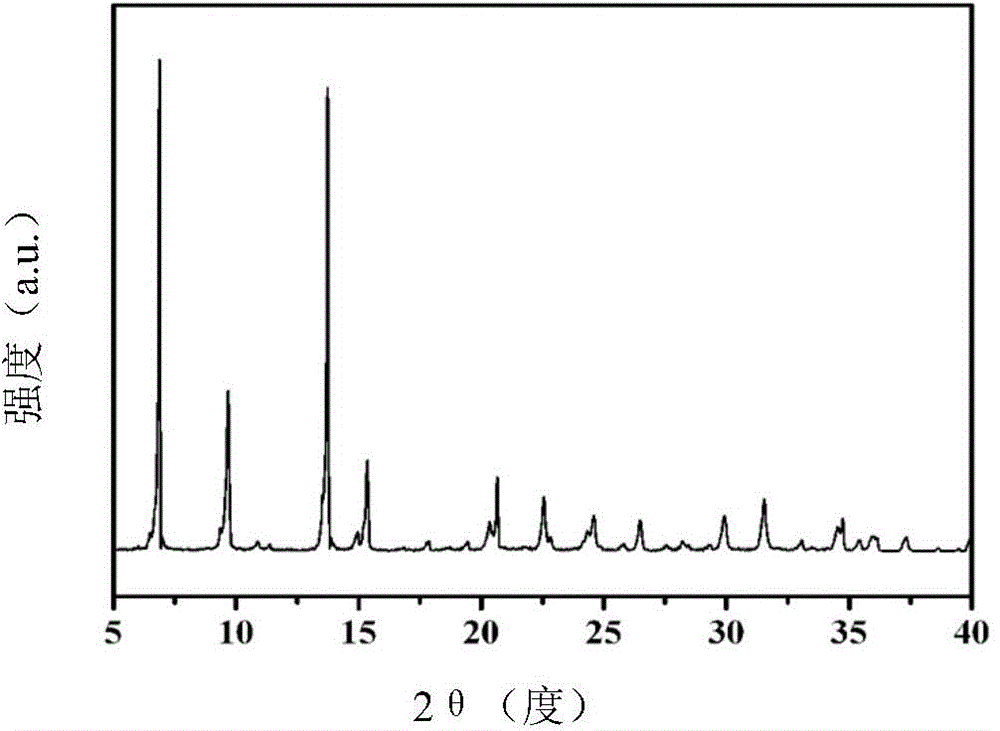

Preparation method for MOF-5 metal-organic frameworks

A metal-organic framework, MOF-5 technology, applied in chemical instruments and methods, other chemical processes, hydrogen separation, etc., can solve the problems of poor interpenetrating MOF-5 crystal quality and high cost, and achieve good thermal stability. Strong hydrogen storage capacity and the effect of improving hydrogen storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

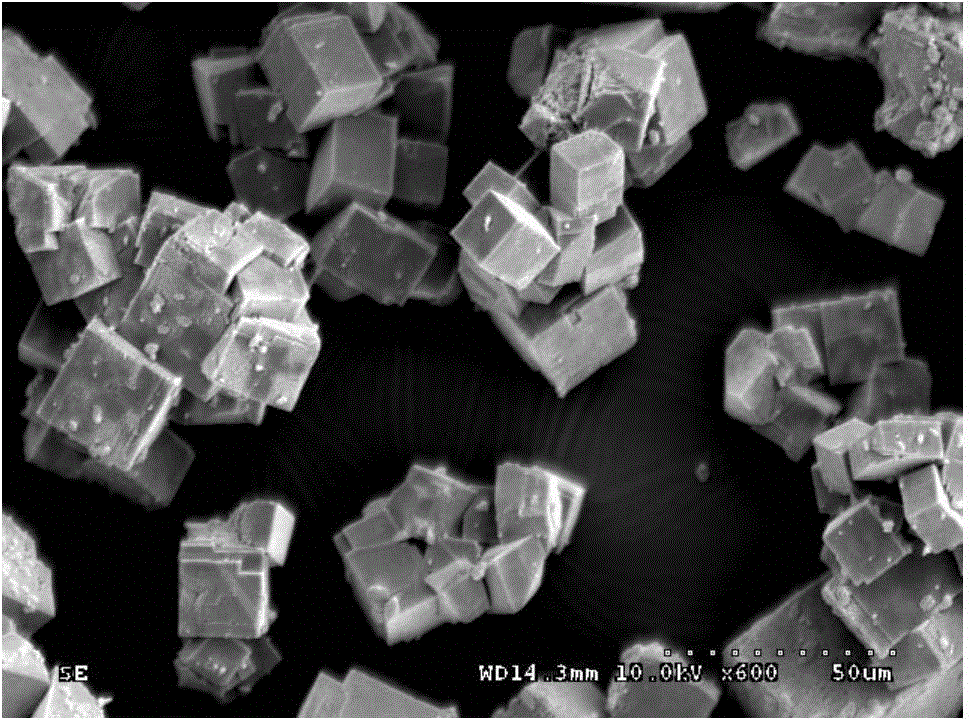

[0067] The MOF-5 metal-organic framework of interpenetrating structure is prepared by a method comprising the following steps:

[0068] 1. Use 10g of 4A molecular sieves to remove water from 500ml of N,N-dimethylformamide (DMF) solvent for 24 hours, set aside. Molecular sieves need to be activated at 400°C for 36 hours before use.

[0069] 2. Get 1.66g zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) and 0.35g terephthalic acid (H 2 BDC) was dissolved in 50 ml of dehydrated DMF solvent, and 550 μL of triethylamine (TEA) was added to immediately produce a white precipitate.

[0070] 3. The white precipitate produced in (2) was filtered off, and the remaining clear solution was heated at 105° C. for 24 hours to produce MOF-5 crystals.

[0071] 4. After the MOF-5 crystals collected in (3) were washed three times with 30ml of dewatered DMF solvent, the MOF-5 crystals were sealed and soaked in 30ml of chloroform at room temperature for 7 days, and the chloroform was changed ever...

Embodiment 2

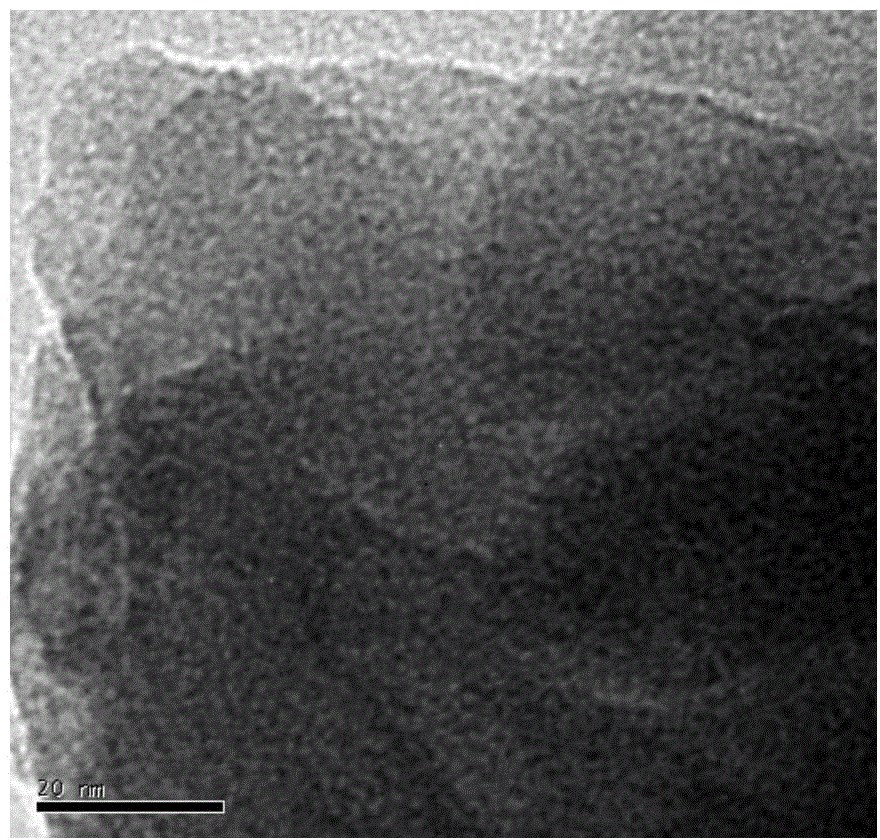

[0075] The MOF-5 metal-organic framework with interpenetrating structure doped with carbon nanotubes is prepared by a method comprising the following steps:

[0076] 1. Use 15g of 4A molecular sieves to remove water from 800ml of N,N-dimethylformamide (DMF) solvent for 36 hours, set aside. Molecular sieves need to be activated at 450°C for 24 hours before use.

[0077] 2. Get 3.33g zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) and 0.71g terephthalic acid (H 2 BDC) was dissolved in 120 ml of dehydrated DMF solvent, and 1100 μL of triethylamine (TEA) was added to immediately produce a white precipitate.

[0078] 3. Filter off the produced white precipitate, add 30 mg of carboxy-functionalized multi-walled carbon nanotubes (MWCNTs) to the remaining clear liquid, and disperse the MWCNTs uniformly by ultrasonication. The solution was heated at 95 °C for 36 h to generate MOF-5 / MWCNTs composites.

[0079] 4. After the MOF-5 / MWCNTs complex collected in 4. was repeatedly washed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com