Preparation method of Pd/Co3O4/foamed nickel electrode materials

An electrode material, foamed nickel technology, applied in the field of preparation of Pd/Co3O4/foamed nickel electrode material, can solve the problems of irreversible harm, accumulated toxicity, chronicity and other problems of human and animals, reduce the probability of electrode side reactions, accelerate Degradation rate, effect of improving current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

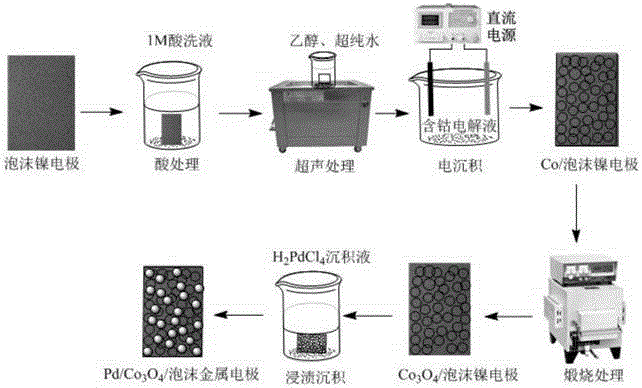

[0026] Pd / Co 3 o 4 / The preparation process of foamed nickel electrode material is as follows figure 1 shown.

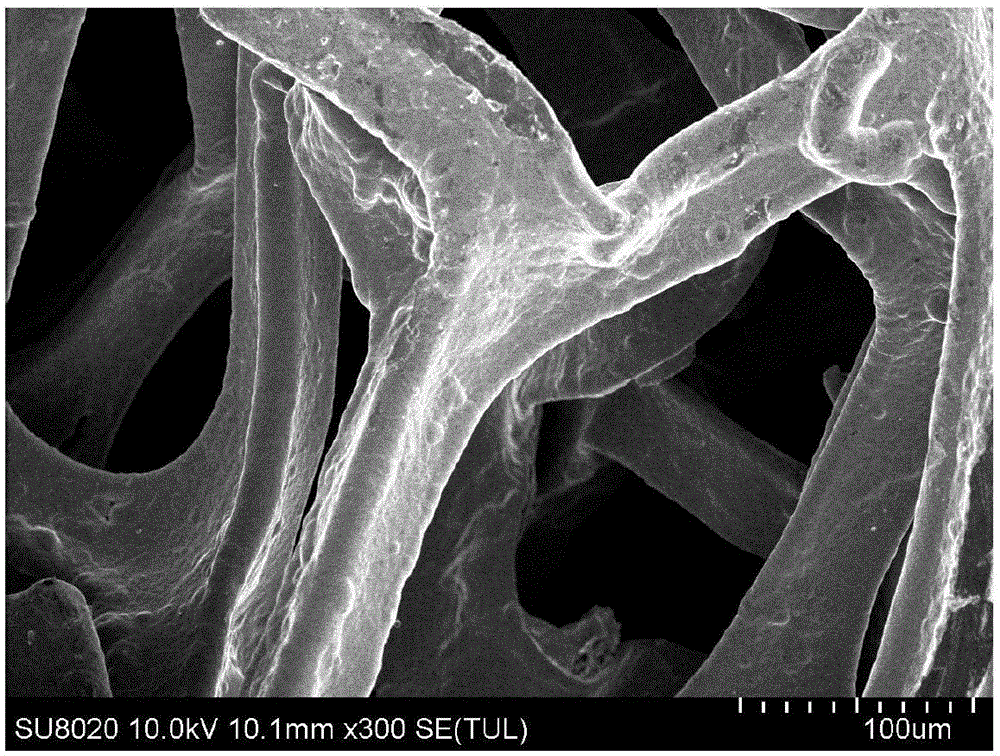

[0027] (1) Electrode pretreatment: First, cut the foamed nickel base material into a size of 3cm×5cm, place the cut foamed nickel base material in 1mol / L H 2 SO 4 or HNO 3 Medium acid treatment for 5 minutes to remove the oxide layer on the surface; then, the acid-treated nickel foam substrate was ultrasonicated in ethanol and deionized water for 15 minutes to remove the oil on the surface.

[0028] (2) Electrodeposition: with 0.01mol / L CoCl 2 and 0.1mol / L Na 2 SO 4 As an electrodeposition solution, an inert graphite electrode was used as an anode, and the pretreated nickel foam substrate was used as a cathode. Under the condition of a water bath at 60 ° C, a constant current of 5 mA was used for 30 min to obtain a Co / foam nickel electrode. The prepared Co / The nickel foam electrode is placed in an oven and dried at 80°C for 1 hour;

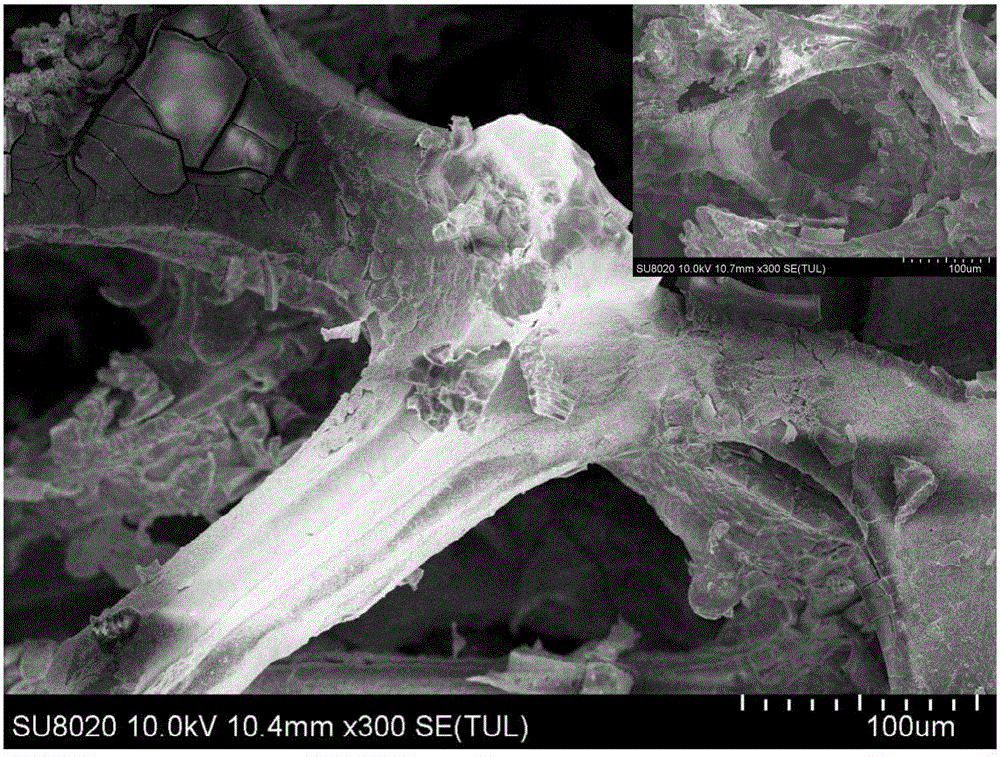

[0029] (3) Calcinatio...

Embodiment 2

[0032] Pd / Co 3 o 4 / The preparation process of foamed nickel electrode material is as followsfigure 1 shown.

[0033] (1) Electrode pretreatment: First, cut the foamed nickel base material into a size of 3cm×5cm, place the cut foamed nickel base material in 0.5mol / L H 2 SO 4 or HNO 3 Medium acid treatment for 8 minutes to remove the oxide layer on the surface; then, the acid-treated nickel foam substrate was ultrasonicated in ethanol and deionized water for 20 minutes to remove the oil on the surface.

[0034] (2) Electrodeposition: with 0.1mol / L CoCl 2 and 0.01mol / L Na 2 SO 4 As an electrodeposition solution, an inert graphite electrode is used as an anode, and the pretreated nickel foam substrate is used as a cathode. Under the condition of a water bath at 60 ° C, a constant current of 15 mA is used for 30 min to obtain a Co / foam nickel electrode. The prepared Co / The nickel foam electrode is placed in an oven and dried at 100°C for 0.5h;

[0035] (3) Calcination: ...

Embodiment 3

[0038] Pd / Co 3 o 4 / The preparation process of foamed nickel electrode material is as follows figure 1 shown.

[0039] (1) Electrode pretreatment: First, cut the foamed nickel base material into a size of 3cm×5cm, place the cut foamed nickel base material in 2mol / L H 2 SO 4 or HNO 3 Medium acid treatment for 3 minutes to remove the oxide layer on the surface; then, the acid-treated nickel foam substrate was ultrasonicated in ethanol and deionized water for 10 minutes to remove the oil on the surface.

[0040] (2) Electrodeposition: with 0.05mol / L Co(NO 3 ) 2 and 0.01mol / L NaNO 3 As an electrodeposition solution, an inert graphite electrode is used as an anode, and the pretreated nickel foam substrate is used as a cathode. Under the condition of a water bath at 80 °C, a constant current of 20 mA is used for electrodeposition for 20 minutes to obtain a Co / foam nickel electrode. The prepared Co / The nickel foam electrode is placed in an oven and dried at 100°C for 2 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com