Method for preparing nitrogen-doped porous carbon material by two-step method and application thereof

A nitrogen-doped porous carbon and two-step technology, which is applied in the field of hydrogen storage materials and new energy materials, can solve the problems of large mesopores and achieve the effects of increased low-temperature hydrogen storage, good reversible adsorption performance, and stability maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

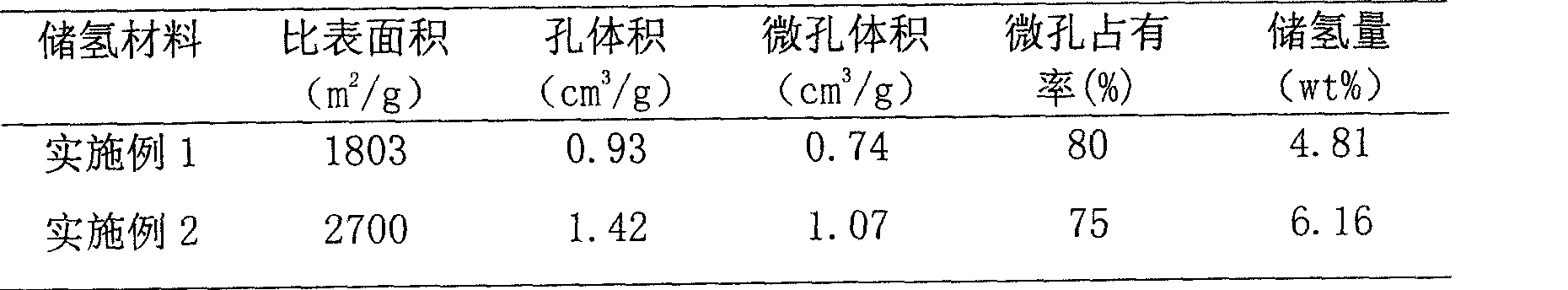

[0018] Using molecular sieve 13X as a template, nitrogen-doped porous carbon was prepared by template carbonization by introducing carbon or carbon-nitrogen precursors through a two-step method, using furfuryl alcohol and acetonitrile as carbon or carbon-nitrogen precursors for liquid impregnation and vapor deposition, respectively. The specific surface area of the 13X used is 674m 2 / g, the pore volume is 0.32cm 3 / g. First weigh 4g 13X and immerse it into a solution consisting of 1.5ml furfuryl alcohol, 10ml absolute ethanol and 0.01g oxalic acid, stir at room temperature for 4h to fully mix, then heat at 60°C and 80°C for 16h, respectively, to obtain The yellow-brown solid powder was put into a tube furnace, and then heated at 150 °C under N 2 Heating under the atmosphere for 3h to complete the pre-polymerization of furfuryl alcohol, then the temperature was raised to 700 ° C, followed by 70cm 3 N / min 2 Pass acetonitrile gas into the gas carrier, and heat for 4 hours ...

Embodiment 2

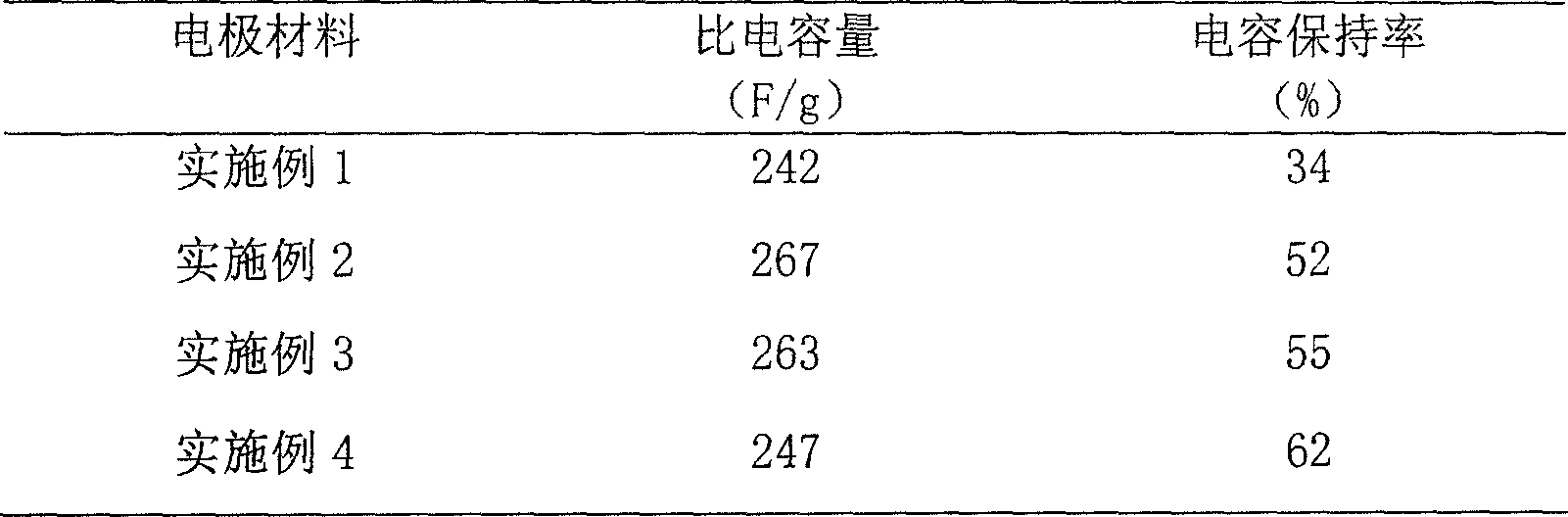

[0021] The method of this example is basically the same as that of Example 1, except that the temperature is raised to 700° C., and then heated for 8 hours under an acetonitrile atmosphere to complete the carbonization of furfuryl alcohol and the deposition of acetonitrile. Figure 1 shows the transmission electron microscope picture of the nitrogen-doped porous carbon material, and the ordered micropore structure can be seen. Figure 2 shows the change of the hydrogen absorption capacity of the nitrogen-doped porous material under different pressures, and it can be seen that the hydrogen absorption capacity increases as the pressure increases. Figure 3 shows the hydrogen absorption and dehydrogenation changes of the nitrogen-doped porous material under different pressures. It can be seen that the entire adsorption process is reversible and can quickly reach the equilibrium of adsorption and desorption. Figure 4 shows the variation of the specific capacitance of the electrode ma...

Embodiment 3

[0023] The method of this example is basically the same as that of Example 1, except that 4g of 13X is immersed in a solution consisting of 3.0ml of furfuryl alcohol, 10ml of absolute ethanol and 0.02g of oxalic acid. The specific test results of the electrode material can be obtained from FIG. 4 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com