Nano-magnesium-based hydrogen storage material and preparation method thereof

A hydrogen storage material, nano-magnesium technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of unsatisfactory hydrogen absorption and desorption kinetics, high dehydrogenation temperature, etc., and achieve excellent Low-temperature hydrogen absorption kinetics and the effect of improving hydrogen storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Put carbon nanofiber powder into concentrated HNO 3 reflux at 140°C for 8 hours, wash with deionized water until neutral and dry after cooling to obtain functionalized carbon nanofiber powder. 0.3g functionalized carbon nanofiber powder and 6g Ni(NO 3 ) 2 ·6H 2 O (the content of nickel accounts for 80% of the total weight of carbon and nickel) is added in the ethanol reagent, dried after ultrasonic mixing; the powder after drying is calcined in the argon atmosphere of 450 ℃ for 3 hours, and then Reduction in a hydrogen atmosphere at 500° C. for 3 hours, and natural cooling to obtain carbon-supported nickel powder. Take 8.5g of magnesium powder and 1.5g of carbon-supported nickel powder and place them in acetone reagent, ultrasonically mix and then dry to obtain magnesium / carbon-supported nickel powder. The magnesium / carbon-supported nickel powder is subjected to hydrogenation combustion synthesis. During the hydrogenation-combustion synthesis process, the magnesium / ...

Embodiment 2

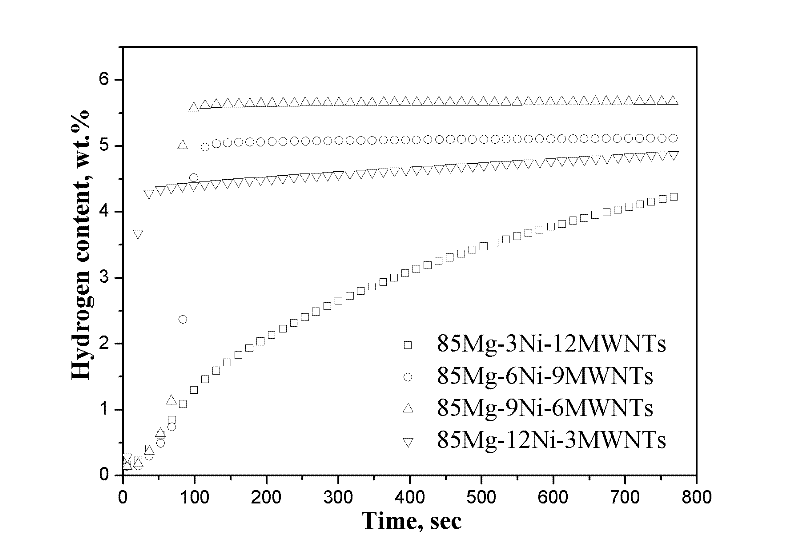

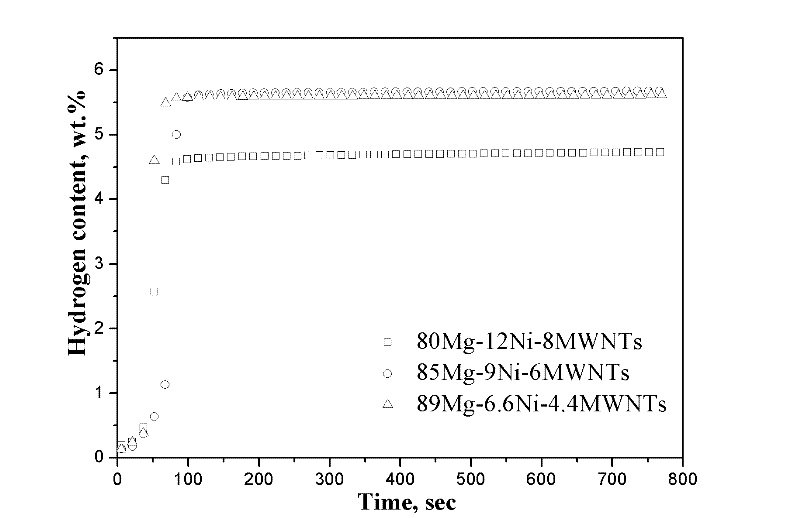

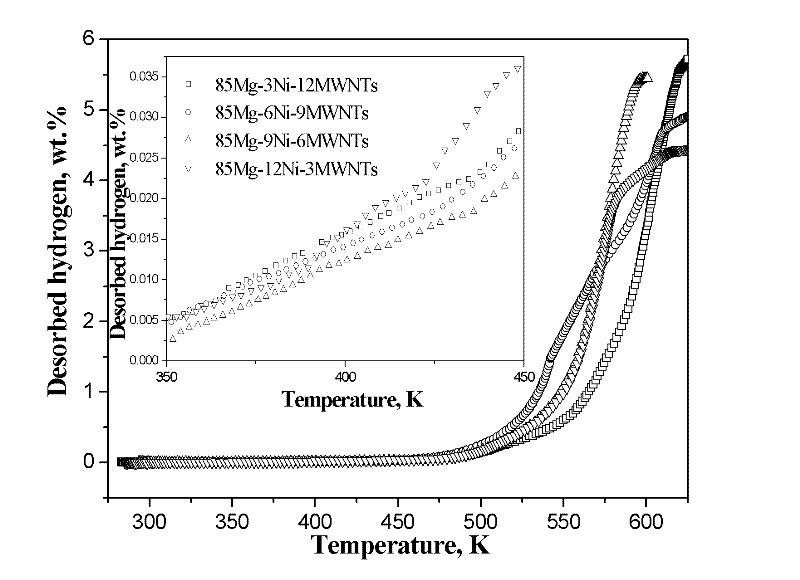

[0032] Putting MWCNT powder into concentrated HNO 3 reflux at 140° C. for 6 hours, wash with deionized water until neutral and dry after cooling to obtain functionalized multi-walled carbon nanotube powder. 0.6g functionalized multi-walled carbon nanotube powder and 4.5g Ni(NO 3 ) 2 ·6H 2 O (the content of nickel accounts for 60% of the total weight of carbon and nickel) is added to the ethanol reagent, dried after ultrasonic mixing; the dried powder is calcined in an argon atmosphere at 400 ° C for 4 hours, and then Reduction in a hydrogen atmosphere at 450° C. for 4 hours, and natural cooling to obtain carbon-supported nickel powder. 8.5g of magnesium powder and 1.5g of carbon-supported nickel powder were placed in acetone reagent, ultrasonically mixed and then dried to obtain magnesium / carbon-supported nickel powder. The magnesium / carbon-supported nickel powder is subjected to hydrogenation combustion synthesis. During the hydrogenation-combustion synthesis process, the...

Embodiment 3

[0035] Putting MWCNT powder into concentrated HNO 3 reflux at 140°C for 7 hours, wash with deionized water until neutral and dry after cooling to obtain functionalized multi-walled carbon nanotube powder. 0.78g functionalized multi-walled carbon nanotube powder and 2.6g Ni(NO 3 ) 2 ·6H 2 O (the content of nickel accounts for 40% of the total weight of carbon and nickel) is added in the ethanol reagent, dried after ultrasonic mixing; the powder after drying is calcined in the argon atmosphere of 380 ℃ for 5 hours, then in Reduction in a hydrogen atmosphere at 470° C. for 5 hours, and natural cooling to obtain carbon-supported nickel powder. 8.7g of magnesium powder and 1.3g of carbon-supported nickel powder were placed in acetone reagent, ultrasonically mixed and then dried to obtain magnesium / carbon-supported nickel powder. The magnesium / carbon-supported nickel powder is subjected to hydrogenation combustion synthesis. During the hydrogenation-combustion synthesis process,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com