Method for nanocrystallization of magnesium-based hydrogen storage material

A hydrogen storage material and nanotechnology, applied in hydrogen production, grain processing, etc., can solve problems such as increasing cost, reducing ductility of ductile materials, and the size of grinding balls not being nanoscale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

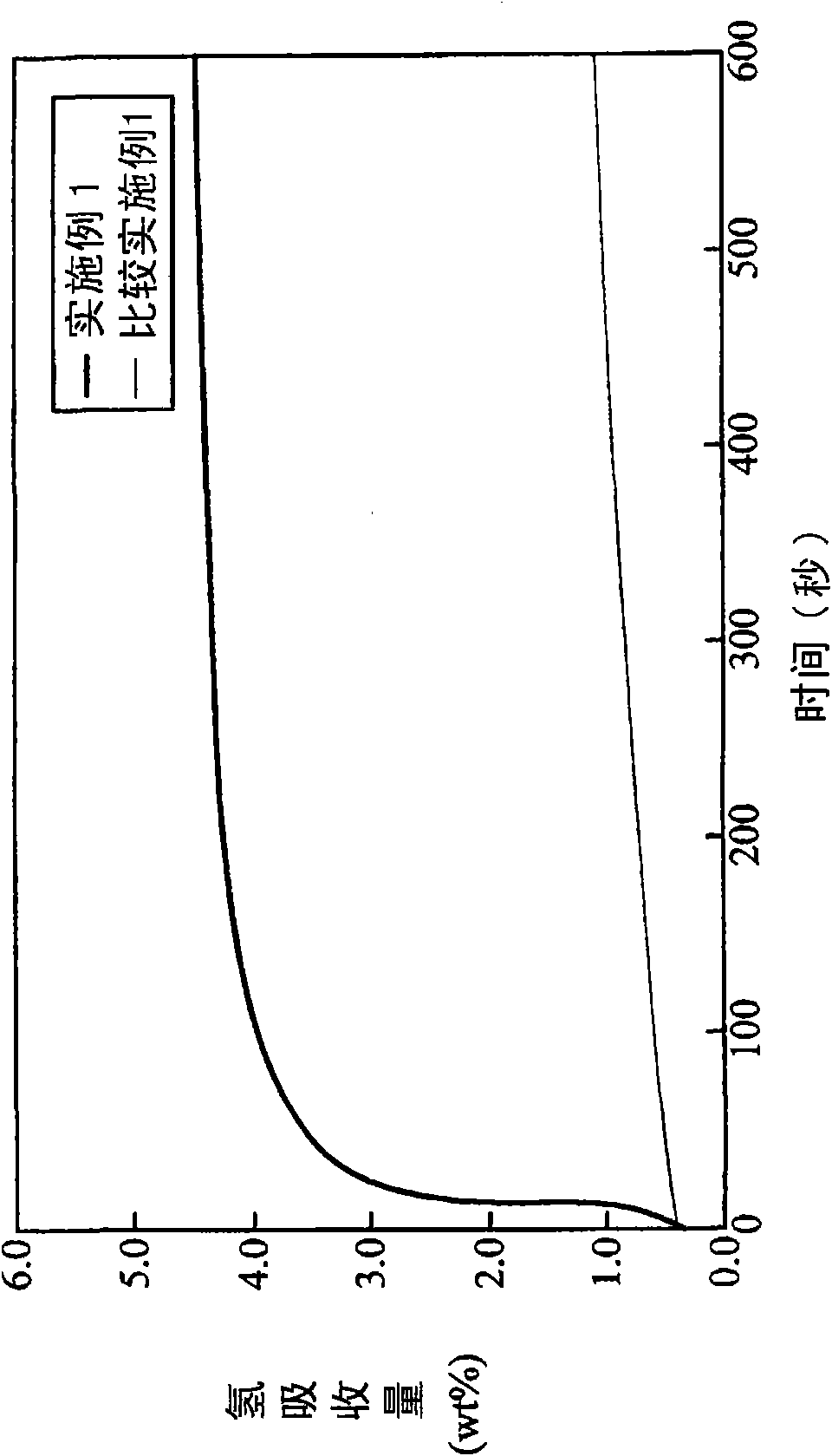

[0016] 0.7 g of magnesium (Weiss Enterprise Co., Ltd.), 0.3 g of FeTi (Simida International Development Co., Ltd.), and 0.01 g of carbon nanotubes (aldrich) were subjected to a ball milling process under argon gas. The grinding beads of the ball milling process are tungsten steel, the temperature is 27, the pressure is 1atm, and the time is 6 hours. According to the XRD diffraction results and transmission electron microscope image analysis, the average crystal of Mg after ball milling is less than 100nm. On the other hand, measuring pressure, hydrogen concentration, and temperature (Pressure-Concentration-Temperature) and other parameters to calculate its hydrogen storage rate, the results are as follows figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com