Method for brazing ceramic and metal by adopting composite high-entropy alloy solder

A technology of high-entropy alloys and composite solders, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve problems affecting the mechanical properties of brazed joints, the type, quantity, shape, and distribution of brittle intermetallic compound phases , to achieve the effect of short cycle, simple operation and favorable mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

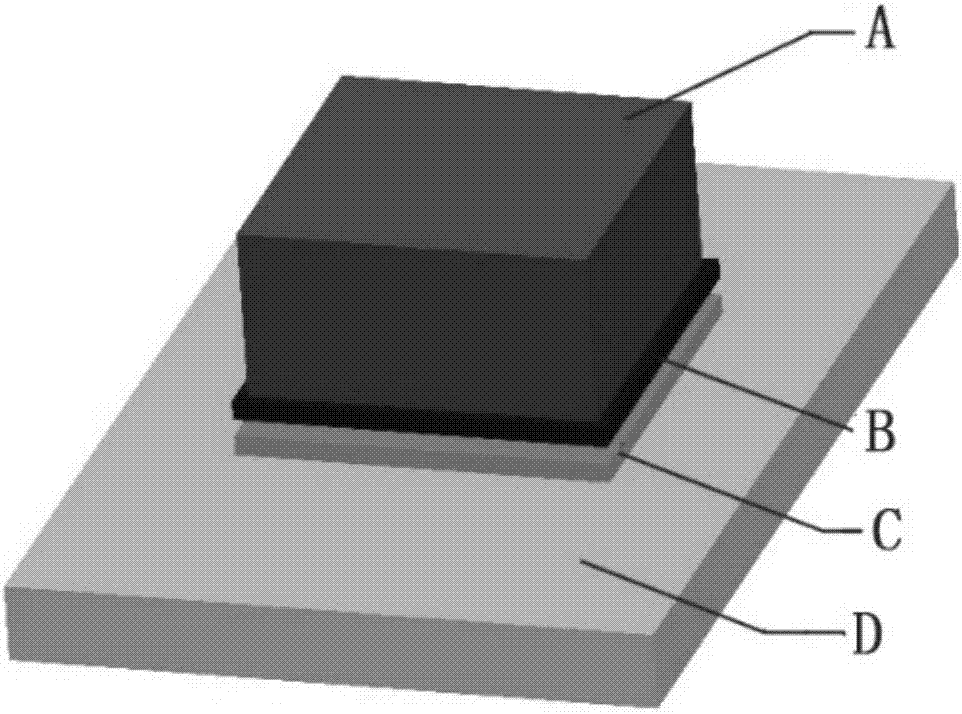

[0027] A method for brazing ceramics and metals with composite high-entropy alloy filler metal, the ceramic base material selected is ZrO 2 Ceramics, the sample size is 5×5×10mm, the metal is Ti-6Al-4V, the specific composition is: Al6.0%, V3.5%, and the rest is Ti. The sample size is 10×10×30mm, the thickness of high-entropy alloy AlNiCu foil is 100μm, and the thickness of titanium foil is 50μm. The width is 5mm.

[0028] After polishing the ceramic and titanium alloy substrates to be welded with 400-mesh, 600-mesh, and 800-mesh water-resistant sandpaper, the substrates were polished with 0.5M diamond grinding fluid, cleaned in acetone and ultrasonic waves for 20 minutes, and dried for later use. , wash the high-entropy alloy foil and titanium foil in acetone for 20 minutes to remove oil and impurities on the surface of the solder, and dry them for use.

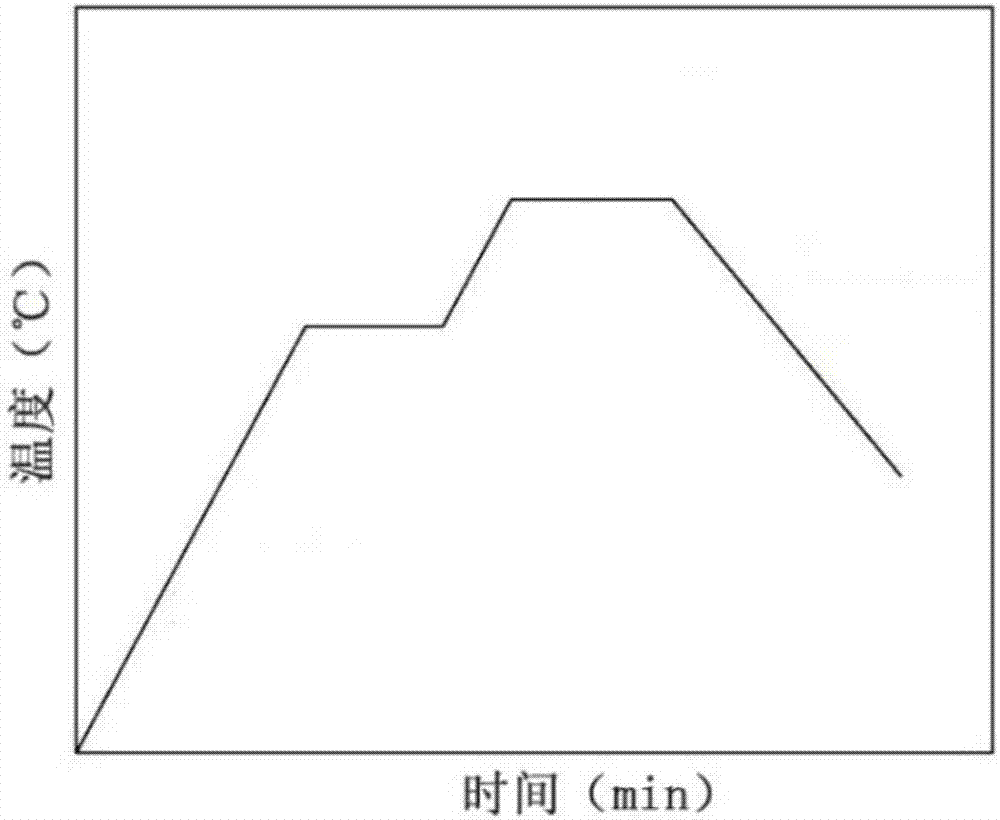

[0029] After assembling the treated substrate and the composite high-entropy solder foil, a pressure of 0.01 MPa was app...

Embodiment 2

[0033] A method for brazing ceramics and metals with composite high-entropy alloy filler metal, the ceramic base material selected is Si 3 N 4 The ceramic sample ruler is 5×5×10mm, and the metal is 304 stainless steel. The sample size is 10×10×30mm, the thickness of high-entropy alloy AlNiCu foil is 100 μm, and the thickness of titanium foil is 50 μm. The width is 5mm.

[0034] After the ceramics to be welded and 304 stainless steel are polished with 400 mesh, 600 mesh, and 800 mesh water-resistant sandpaper, respectively, the substrate is polished with 0.5M diamond abrasive liquid, placed in acetone, cleaned by ultrasonic waves for 20 minutes, and dried for use. Wash the high-entropy alloy foil and titanium foil in acetone for 20 minutes to remove oil and impurities on the surface of the solder, and dry them for use.

[0035] After assembling the treated substrate and the composite high-entropy solder alloy foil, a pressure of 0.02 MPa was applied on the metal to ensure th...

Embodiment 3

[0039] A method for brazing ceramics and metals with composite high-entropy alloy filler metal, the ceramic base material selected is Al 2 o 3 The ceramic sample size is 5×5×10mm, the metal is Ti-6Al-4V, and the specific composition is: Al6.0%, V3.5%, and the rest is Ti. The sample size is 10×10×30 mm, the thickness of the high-entropy alloy AlNiCu foil strip is 100 μm, and the thickness of the titanium foil is 50 μm. The width is 5mm.

[0040] Will be welded Al 2 o 3 The ceramics and Ti-6Al-4V alloy were polished with 400 mesh, 600 mesh, and 800 mesh water-resistant sandpaper respectively, and then the substrate was polished with 0.5M diamond abrasive liquid, cleaned in acetone and ultrasonic wave for 20 minutes, and dried for later use. Wash the high-entropy alloy foil and titanium foil in acetone for 20 minutes to remove oil and impurities on the surface of the solder, and dry them for use.

[0041] After assembling the treated substrate and the composite high-entropy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Room temperature shear strength | aaaaa | aaaaa |

| Room temperature shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com