Heat conduction electromagnetic shielding composite material and preparation method thereof

A composite material, electromagnetic shielding technology, applied in the fields of magnetic field/electric field shielding, chemical instruments and methods, electrical components, etc., can solve the problems of the folding method, which is difficult to produce in large quantities and quickly, difficult to obtain thick graphite sheets, and thick graphite sheets. Achieve the effect of flexible adjustment of appearance and size, simple structure and processing technology, and improved vertical thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

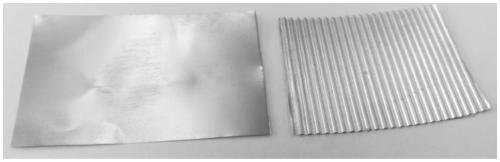

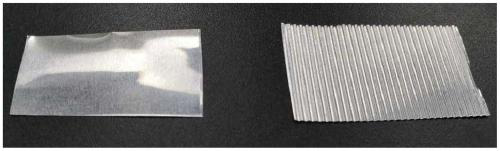

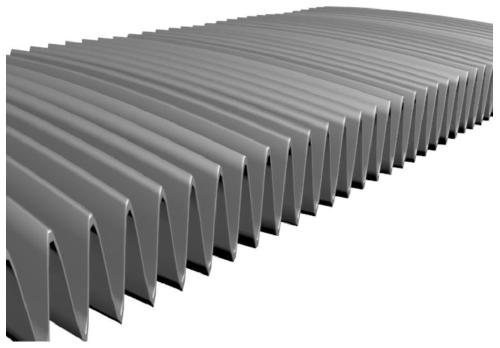

[0042] First, the copper foil with a thickness of 50 μm is cut into long strips ( figure 1 Left), the cut copper foil is put into a mechanical device, and after rolling, a copper foil with a vertically oriented structure is obtained ( figure 1 Right), converting the high thermal conductivity in the horizontal plane of the copper foil to the high thermal conductivity out-of-plane in the vertical direction. The mixture of premixed epoxy resin and dicyandiamide and 1-cyanoethyl-2-ethyl-4-methylimidazole (mass ratio is 100:50:20) is poured on the oriented copper foil, The liquid epoxy resin will permeate and fill the gaps of the copper foil, and it will be cured after being heated at 120°C for 2 hours to obtain a copper foil composite material filled with epoxy resin and having a vertically oriented structure inside. Its thermal conductivity is 15W / m·K, and its shielding effectiveness is 60dB from 10MHz to 1GHz.

Embodiment 2

[0044] The same as the method of embodiment 1, the difference is only that the mixture of premixed epoxy resin and ethylenediamine and ethyl acetate (mass ratio is 100:8:20) is mixed uniformly with thermally conductive filler spherical alumina (aluminum oxide content of 90wt%), die-cast it into the gap of the copper foil with the orientation structure with a flat plate, heat at 120°C for 2 hours, and then solidify and form it to obtain a copper foil composite material with a vertical orientation structure filled with epoxy resin / alumina. Since epoxy / alumina is thermally conductive but insulating, the composite can be used as an insulating thermal interface material with high thermal conductivity, and its electromagnetic shielding performance comes only from copper foil. Its thermal conductivity is 25W / m·K, and its shielding effectiveness is 60dB from 10MHz to 1GHz.

Embodiment 3

[0046] Identical to the method of embodiment 1, the difference is only that the mixture of premixed epoxy resin and diaminomethylcyclohexane and triphenyl phosphite (mass ratio is 100:18:5) and carbon nanotube After the n-hexane dispersion is blended uniformly (the content of carbon nanotubes is 12wt%), it is poured into the gap of the copper foil with an orientation structure, and it is cured after heating at 150°C for 4h to obtain an epoxy resin / carbon nanotube filled interior with a vertical Oriented copper foil composites. Its thermal conductivity is 20W / m·K, and its shielding effectiveness is 80dB from 10MHz to 1GHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com