Manufacturing method of flexible all-solid-state array type perovskite solar battery

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems that affect production efficiency, unfavorable device stability, and inability to capture change information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

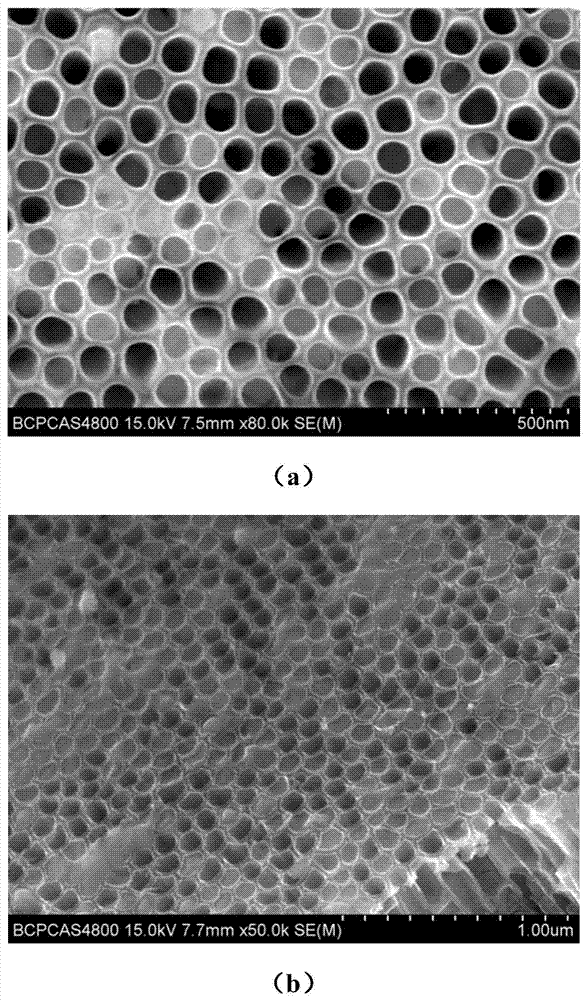

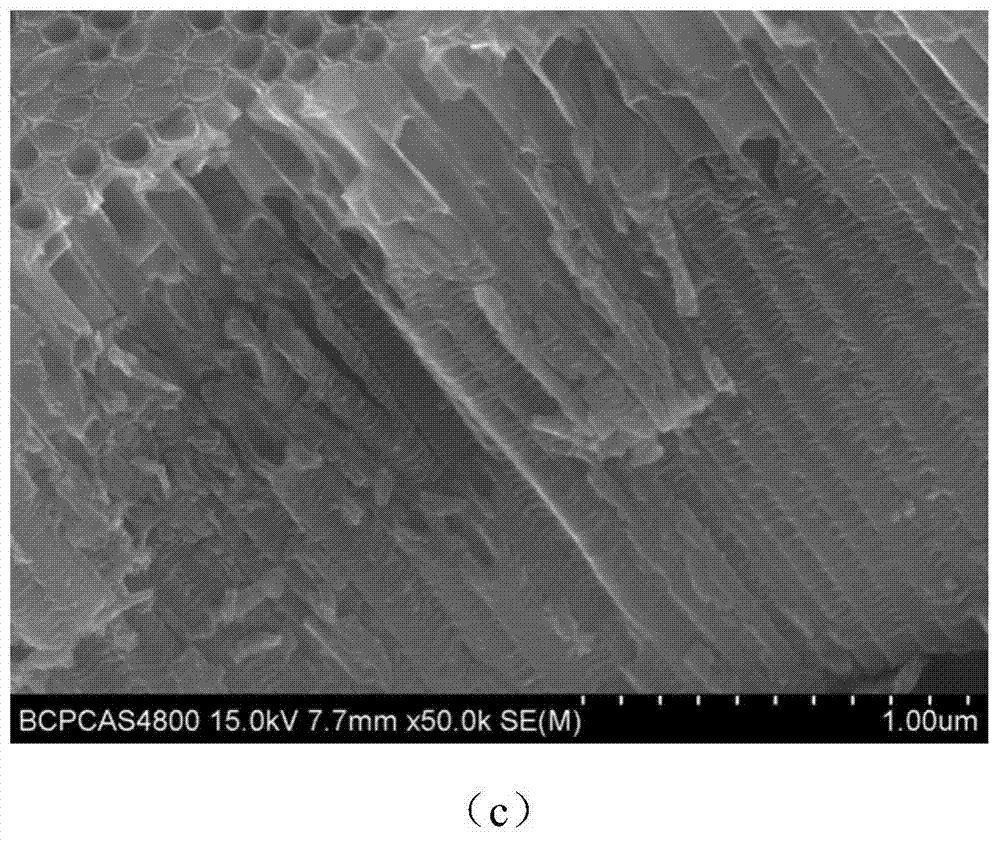

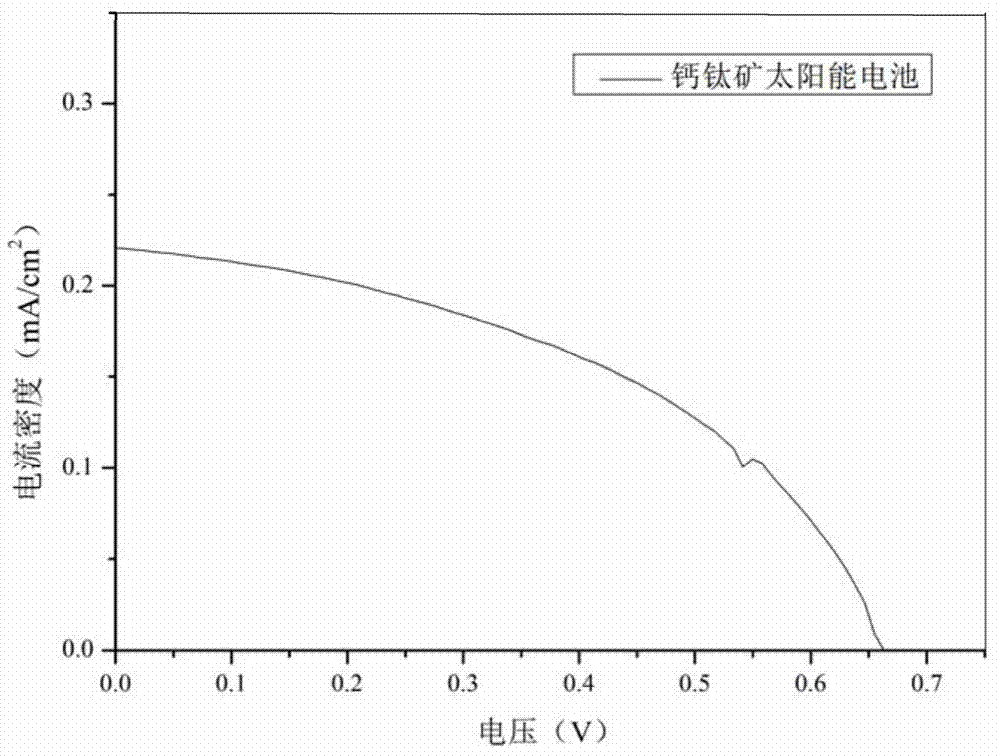

[0017] The metal titanium sheet was pre-treated, pulse anodized in an electrolyte solution containing fluorine ions for 100 minutes, taken out, rinsed with deionized water, and dried; prepared 0.5925g CH 3 NH 3 I powder with 1.7355g PbI 2 Particles, keeping the molar ratio of 1:1, were dissolved in 0.5mL of γ-butyrolactone solution, and stirred at 40°C for 16h. The perovskite sensitizer was spin-coated on the surface of the titanium dioxide nanotube array and the inner and outer walls of the tube at a spin-coating speed of 1kr / min within 5s, and formed CH after drying. 3 NH 3 PB 3 / TiO 2 Structure: 126 mg of hole transport material HTM was dissolved in 0.5 mL of chlorobenzene and stirred to form a solution, which was spin-coated on CH at a spin-coating speed of 4 kr / min for 5 s. 3 NH 3 PB 3 / TiO 2 on, after drying to form HTM / CH 3 NH 3 PB 3 / TiO 2 Structure; Au counter electrode deposited on HTM / CH by magnetron sputtering 3 NH 3 PB 3 / TiO 2 on, forming Au / HTM / C...

Embodiment 2

[0019] The metal titanium sheet was pre-treated, pulse anodized in an electrolyte solution containing fluorine ions for 100 minutes, taken out, rinsed with deionized water, and dried; prepared 0.5925g CH 3 NH 3 I powder with 1.7355g PbI 2 Particles, keeping the molar ratio of 1:1, were dissolved in 1mL of γ-butyrolactone solution, and stirred at 50°C for 20h. The perovskite sensitizer was spin-coated on the surface of the titanium dioxide nanotube array and the inner and outer walls of the tube at a spin-coating speed of 2kr / min within 10s, and formed CH after drying. 3 NH 3 PB 3 / TiO 2 Structure: 126mg of hole transport material HTM was dissolved in 1mL of chlorobenzene and stirred to form a solution, which was spin-coated on CH at a spin-coating speed of 5kr / min within 10s. 3 NH 3 PB 3 / TiO 2 on, after drying to form HTM / CH 3 NH 3 PB 3 / TiO 2 Structure; Au counter electrode deposited on HTM / CH by magnetron sputtering 3 NH 3 PB 3 / TiO 2 on, forming Au / HTM / CH ...

Embodiment 3

[0021] The metal titanium sheet was pre-treated, pulse anodized in an electrolyte solution containing fluorine ions for 100 minutes, taken out, rinsed with deionized water, and dried; prepared 0.5925g CH 3 NH 3 I powder with 1.7355g PbI 2 The particles, keeping the molar ratio of 1:1, were dissolved in 1.5mL of γ-butyrolactone solution respectively, and stirred at 60°C for 24h. The perovskite sensitizer was spin-coated on the surface of the titanium dioxide nanotube array and the inner and outer walls of the tube at a spin-coating speed of 3kr / min within 15s, and formed CH after drying. 3 NH 3 PB 3 / TiO 2 Structure: 126mg of hole transport material HTM was dissolved in 1.5mL of chlorobenzene and stirred to form a solution, which was spin-coated on CH at a spin-coating speed of 6kr / min for 15s. 3 NH 3 PB 3 / TiO 2 on, after drying to form HTM / CH 3 NH 3 PB 3 / TiO 2 Structure; Au counter electrode deposited on HTM / CH by magnetron sputtering 3 NH 3 PB 3 / TiO 2 on, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com