Preparation method of titanium dioxide nanotube film

A titanium dioxide and nanotube technology, which is applied in the fields of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of large inner diameter of nanotubes, complicated experimental operations, and tube wall thickness, and achieves good integrity and cost. Inexpensive, simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1, raw material pretreatment:

[0028] Cut the pure titanium foil into length×width: 2cm×1cm, put it in acetone solution for ultrasonic cleaning for 10min, and then place it in a molar ratio of HF:HNO 3 :H 2 Polish in a solution of O=1:4:5 for 15 minutes until no bubbles are violently generated, then ultrasonically clean in distilled water for 5 minutes, and dry at room temperature;

[0029] Step two, chemical treatment:

[0030] The pretreated pure titanium foil was placed in a hydrochloric acid solution with a mass fraction of 36%, treated at room temperature for 8 days, then rinsed with distilled water, and dried at room temperature;

[0031] Step three, hydrothermal treatment:

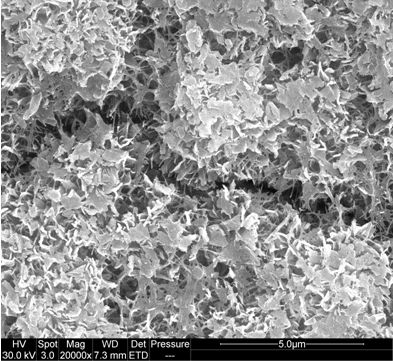

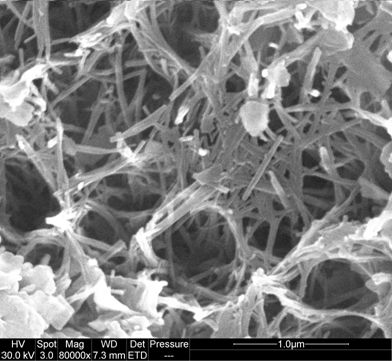

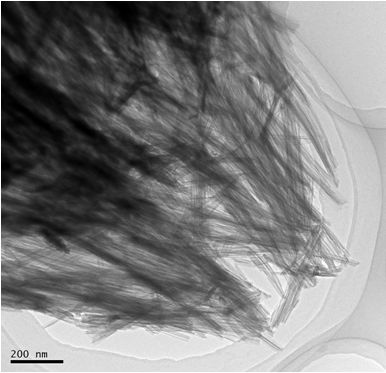

[0032] Put the chemically treated pure titanium foil into a high-pressure reactor, and conduct a hydrothermal reaction for 20 hours in a 5mol / L sodium hydroxide solution at 140°C and a steam pressure of 0.361MPa. After the hydrothermal reaction is completed, take out the titanium she...

Embodiment 2

[0037] Step 1, raw material pretreatment:

[0038] Put the pure titanium foil with a length×width of 2cm×1cm into the acetone solution and ultrasonically clean it for 10min, and then place it in a molar ratio of HF:HNO 3 :H 2 Polish in a solution of O=1:4:5 for 15 minutes until no bubbles are violently generated, then ultrasonically clean in distilled water for 5 minutes, and dry at room temperature;

[0039] Step two, chemical treatment:

[0040] The pretreated pure titanium foil was placed in a hydrochloric acid solution with a mass fraction of 40%, treated at room temperature for 2 days, then rinsed with distilled water, and dried at room temperature;

[0041] Step three, hydrothermal reaction

[0042] Put the chemically treated pure titanium foil into a high-pressure reactor, and conduct a hydrothermal reaction for 25 hours in a 5mol / L sodium hydroxide solution at 170°C and a steam pressure of 0.792MPa. After the hydrothermal reaction is over, take out the titanium shee...

Embodiment 3

[0047] Step 1, raw material pretreatment:

[0048] Put the pure titanium foil with the length × width: 2cm × 1cm in the acetone solution for ultrasonic cleaning for 10min, and then put it in the molar ratio of HF:HNO 3 :H 2 Polish in a mixed solution of O=1:4:5 for 15 minutes until no bubbles are violently generated; then place in distilled water for ultrasonic cleaning for 5 minutes, and dry at room temperature;

[0049] Step two, chemical treatment:

[0050] The pretreated titanium foil was placed in a hydrochloric acid solution with a mass fraction of 30%, treated at room temperature for 5 days, then rinsed with distilled water, and dried at room temperature;

[0051] Step three, hydrothermal treatment:

[0052] Put the chemically treated pure titanium foil into a high-pressure reaction kettle, and conduct a hydrothermal reaction for 30 hours in a 7mol / L sodium hydroxide solution at 150°C and a steam pressure of 0.476MPa, and then wash it repeatedly with distilled water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com