Production method of low-alloy complex-phase (Q and P) steel

A production method and low-alloy technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems that the performance of steel used in automobile manufacturing cannot be well satisfied, the process is cumbersome, and the energy consumption is high, and a good comprehensive The effect of mechanical properties, simplifying process flow and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

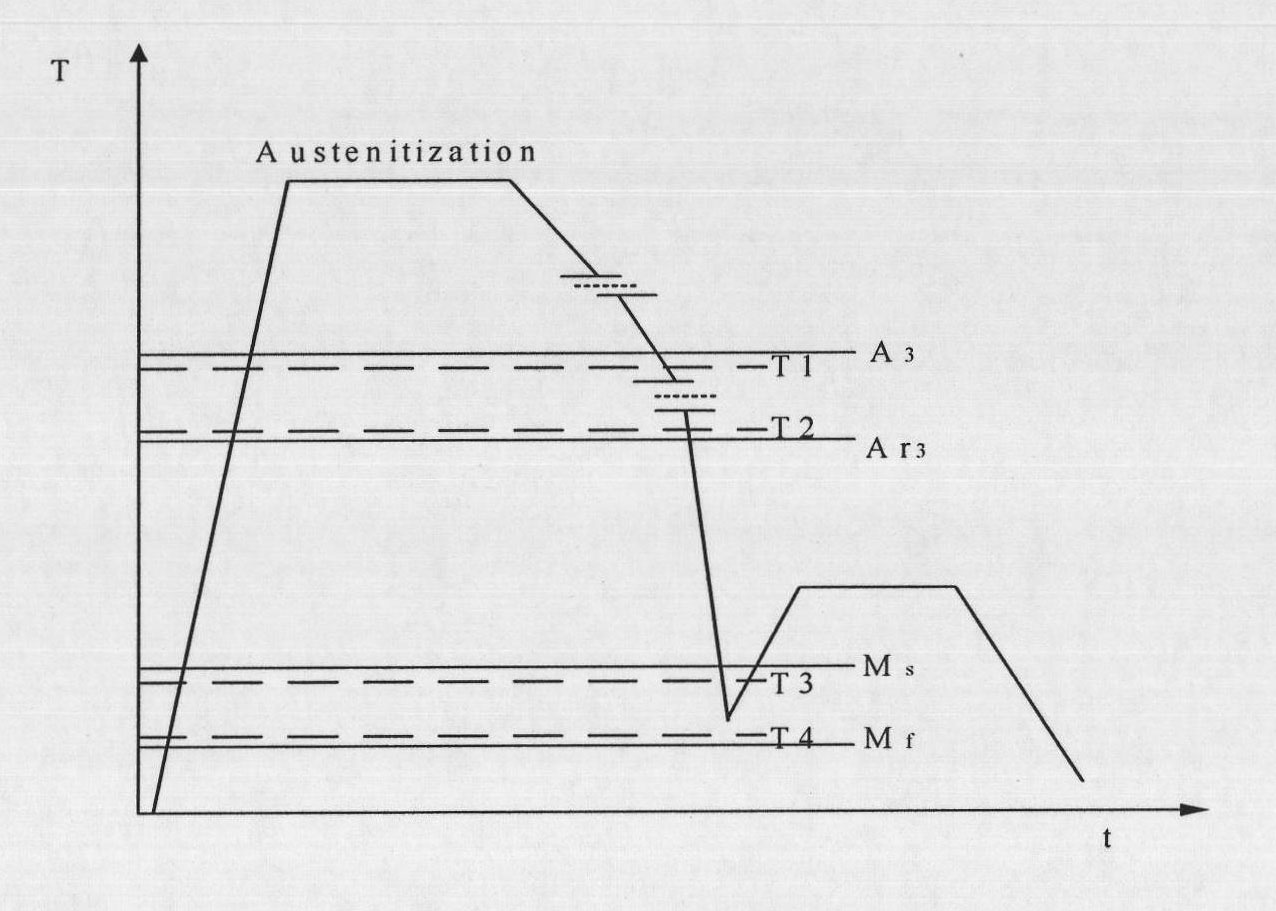

[0028] The chemical composition of selected raw material steel is calculated by weight percentage: C: 0.2, Mn: 1.50, Si: 1.60, N: 0.0034, P: 0.02, S<0.0045, O<0.003, and the balance is Fe and unavoidable impurities.

[0029] The production steps are as follows:

[0030] 1) Heat the billet to 1100°C and keep it warm for 120 minutes;

[0031] 2) Then cool it to 1000°C at a rate of 5°C / s;

[0032] 3) Take 1s again -1 Rough rolling is carried out at a strain rate of 100%, and 2 passes of deformation are carried out during rough rolling, and the strain of each pass is controlled at 50%;

[0033] 4) After rough rolling, cool down to 780°C at a rate of 5°C / s (the A of this steel is measured by thermal expansion method) r3 It is 750 ℃, use Thermo-Calc software to calculate the A of this steel 3 is 863°C);

[0034] 5) Take another 50s -1 Finish rolling is carried out at a certain strain rate, and 3 passes of deformation are carried out during finish rolling, and the strain of eac...

Embodiment 2

[0040] The chemical composition of the selected raw material steel is calculated by weight percentage: C: 0.2, Mn: 1.50, Si: 0.50, Al: 1.0, and the balance is Fe and unavoidable impurities.

[0041] The production steps are as follows:

[0042] 1) Heat the billet to 1250°C and keep it warm for 5 minutes;

[0043] 2) Then cool it to 1100°C at a speed of 20°C / s;

[0044] 3) Take another 50s -1 Rough rolling is carried out at a strain rate of 20%, and 3 passes of deformation are implemented during rough rolling, and the strain of each pass is controlled to be 20%;

[0045] 4) After rough rolling, cool down to 800°C at a rate of 50°C / s (the A of this steel is measured by thermal expansion method) r3 is 780°C, use Thermo-Calc software to calculate the A of this steel 3 is 974°C);

[0046] 5) Take 1s again -1 Finish rolling at a certain strain rate, 3-pass deformation is carried out at the finishing rolling rate, and the strain of each pass is controlled at 30%;

[0047] 6) I...

Embodiment 3

[0052] The chemical composition of the selected steel grade is the same as in Example 2.

[0053] The production steps are as follows:

[0054] 1) Heat the billet to 1200°C and keep it warm for 100 minutes;

[0055] 2) Then cool it to 1050°C at a speed of 10°C / s;

[0056] 3) Take another 25s -1 Rough rolling is carried out at a strain rate of 100%. During rough rolling, 2 passes of deformation are carried out, and the strain of each pass is controlled to be 30%;

[0057] 4) After rough rolling, cool down to 800°C at a rate of 30°C / s (the A of this steel is measured by thermal expansion method) r3 is 780°C, use Thermo-Calc software to calculate the A of this steel 3 is 974°C);

[0058] 5) Take another 20s -1 The strain rate of the finish rolling is carried out, and the deformation is carried out in 3 passes during the finish rolling, and the strain amount of each pass is controlled to 25%;

[0059] 6) Immediately after finish rolling, cool to 150°C at 60°C / s;

[0060] 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com