Double-medium multi-stage expansion packer and clamping and plugging method

A dual-media, packer technology, applied in the direction of sealing/isolation, earthwork drilling, mining fluid, etc., can solve the problems of insufficient sealing length, failure to meet the demand, and failure to meet the sealing demand, etc., to reduce the shoulder The effect of the stress concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The detailed description and technical content of the present invention are described below in conjunction with the accompanying drawings. However, the accompanying drawings are only for reference and description, and are not used to limit the present invention.

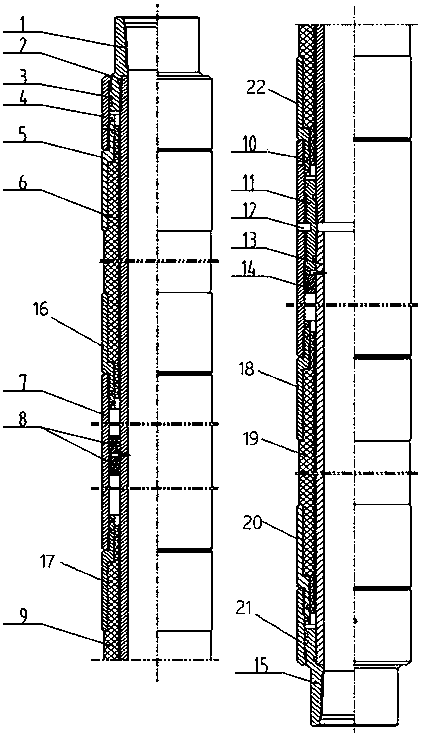

[0025] according to figure 1 As shown, the dual-medium multi-stage expansion packer includes a center tube and a rubber tube sleeved on the outer wall of the center tube. The rubber tube includes an upper shoulder short rubber tube 6, a middle long rubber tube 9, and a lower shoulder short rubber tube 19. The length of the middle and long rubber cylinder is greater than the length of the upper shoulder short rubber cylinder, and at the same time greater than the length of the lower shoulder short rubber cylinder, the hardness of the middle and long rubber cylinder is less than the hardness of the upper shoulder short rubber cylinder, At the same time, it is also less than the hardness of the lower shoulder short ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com