A kind of fiber-reinforced polymer-based composite material T-joint and its manufacturing method

A composite material and fiber-reinforced technology, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of destroying the stress conduction between the vertical web and the lower wall, the destruction of the T-joint structure, and uneven stress distribution. , to achieve the effect of improving tensile and bending properties, excellent tensile and bending properties, high toughness and damage tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

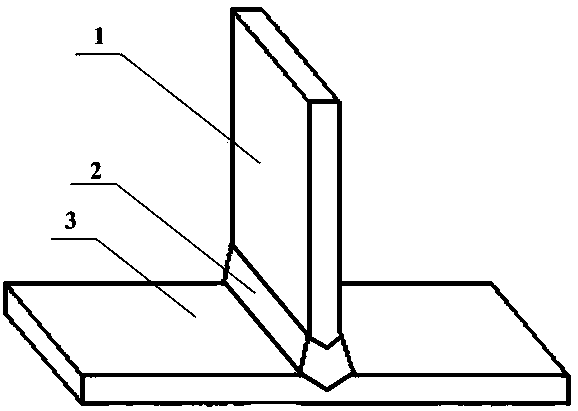

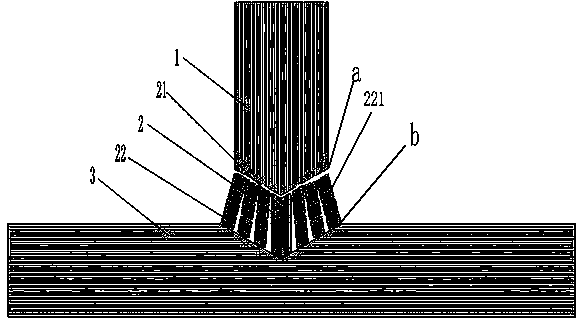

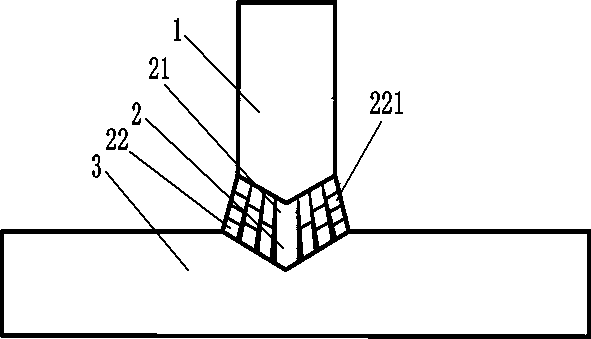

[0020] see figure 1 , figure 2 and image 3 As shown, the fiber-reinforced polymer-based composite T-joint of the present invention is composed of a vertical web 1, a bionic transition fillet area 2 and a lower wall plate 3, and the two ends of the bionic transition fillet area 2 are respectively fixedly connected to the vertical web 1 and the lower wall plate 3; the bionic transition fillet area 2 includes a tensile unit body 21 and several anti-bending unit rows 22, and several anti-bending unit rows 22 are arranged on both sides of the tensile unit body 21, and the bending-resistant unit row 22 There are several composite material unit sections 221; the interface bonding angle a between the vertical web 1 and the bionic transition fillet area 2 is limited to 100°-120°, and the interface between the bionic transition fillet area 2 and the lower wall plate 3 The interface bonding angle b is limited between 100°-120°;

[0021] The materials of the vertical web 1, the lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com