Pure shear fatigue test device for metal web plate

A fatigue test and pure shearing technology, applied in the direction of measuring devices, using stable shearing force to test the strength of materials, instruments, etc., can solve the problems of crack initiation, damage, and difficulty in determining fatigue weak parts, so as to reduce stress concentration effect, increase utilization, avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following detailed description of the preferred embodiment, reference is made to the accompanying drawings which form a part hereof. The accompanying drawings show, by way of example, specific embodiments in which the invention can be practiced. The illustrated embodiments are not intended to be exhaustive of all embodiments in accordance with the invention. It is to be understood that other embodiments may be utilized and structural or logical changes may be made without departing from the scope of the present invention.

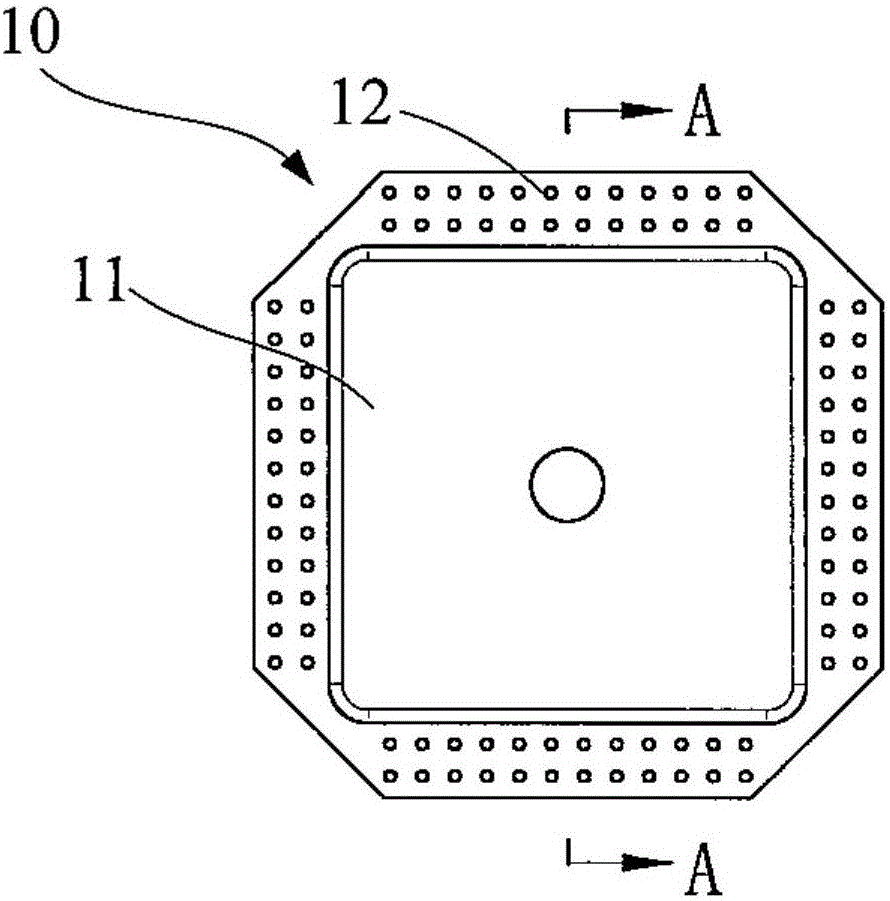

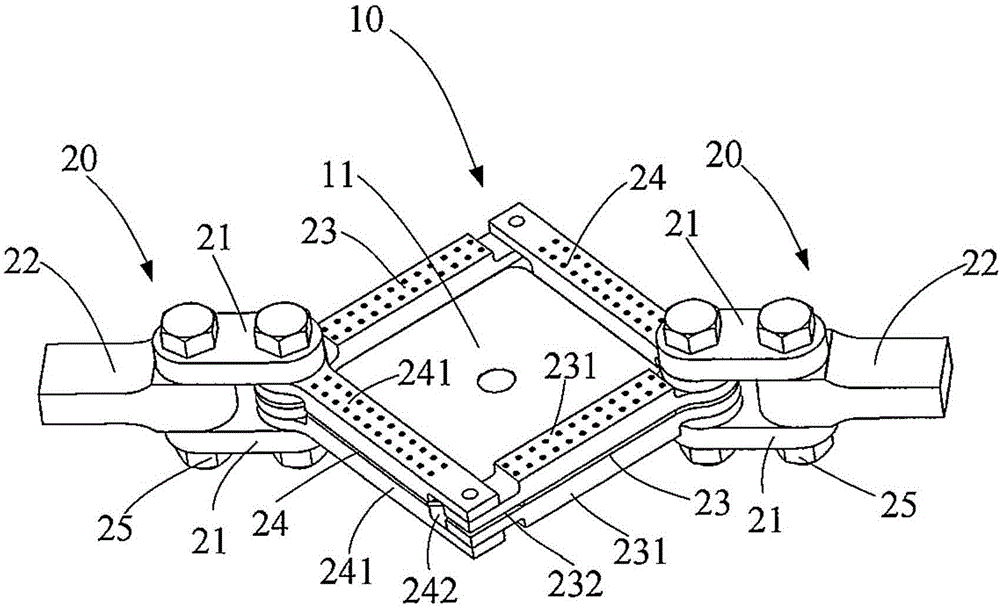

[0021] Such as Figure 1-3 As shown in , the metal web pure shear fatigue test device according to the present invention mainly includes a square metal web 10 and a clamp assembly. The metal web 10 has four chamfered portions and generally has an octagonal configuration. Preferably, the shape of the metal web 10 is an octagon with plane symmetry. The metal web 10 comprises a central area 11 and a peripheral area 12 , the thickness of which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com