Radial pushing and pressing fastening type shield segment joint and construction method

A shield segment and fastening technology, which is applied in the field of radial push and fasten shield segment joints and construction, can solve the problems of inconvenience, easy failure and installation of segment joints, and achieve easy replacement and maintenance, The effect of reducing joint waterproof failure and reducing the risk of concrete fracturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

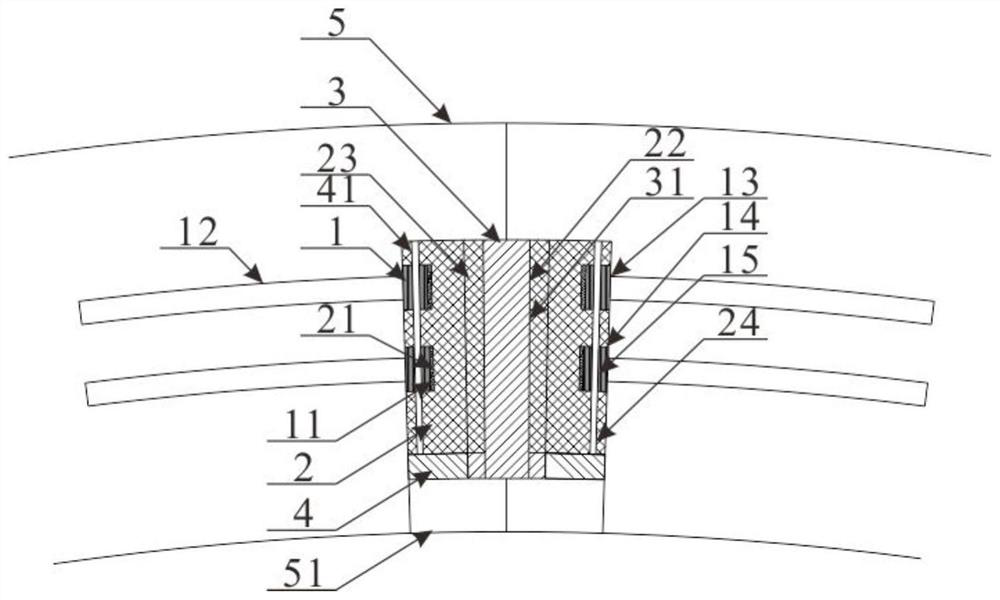

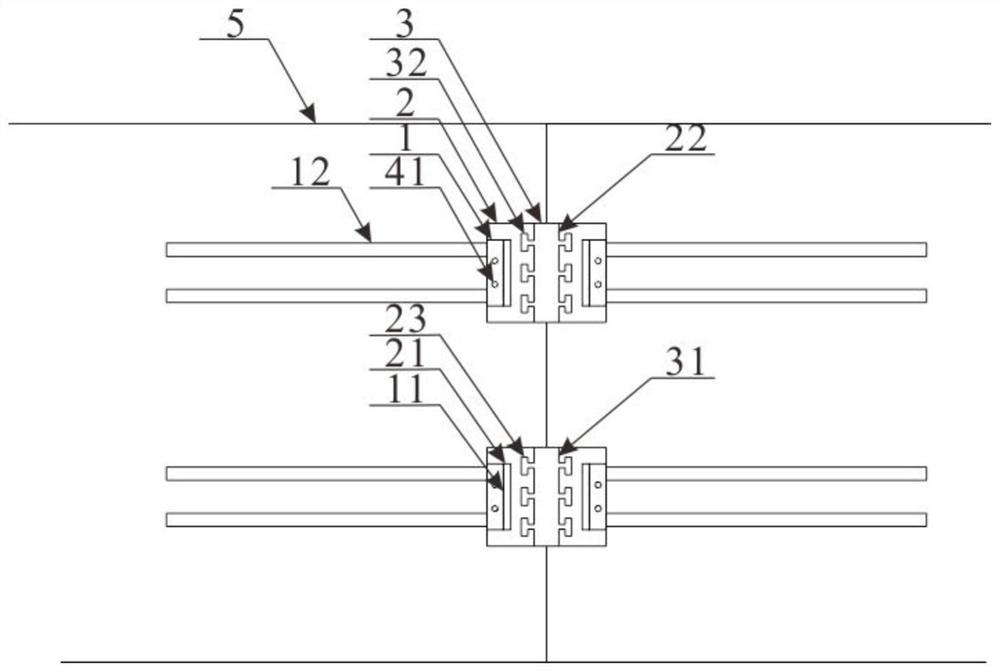

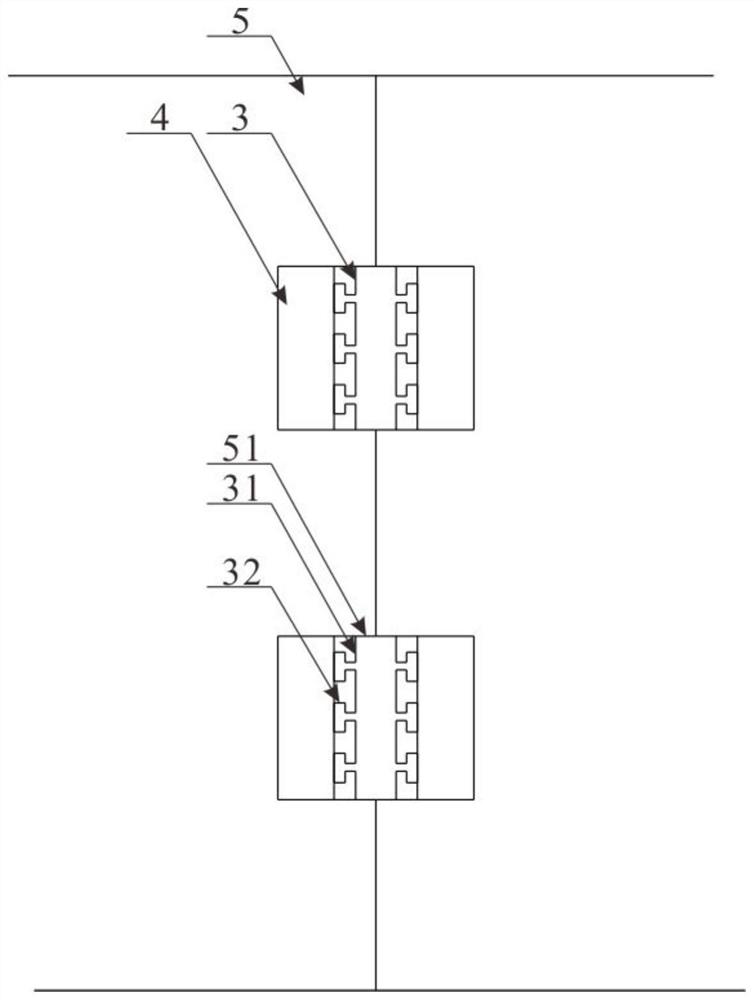

[0031] Such as figure 1 As shown in , it is a structural schematic diagram of the radial push fastening shield segment joint.

[0032] The radial push fastening type shield segment joint of the present invention includes several connecting grooves 51 arranged symmetrically on the ends of the secondary lining segments 5, and the connecting grooves 51 are connected to the inner side of the tunnel; the connecting grooves 51 The outer arc surface joint 13 and the inner arc surface joint 14 which are parallel to each other are respectively installed inside.

[0033] Such as figure 2 As shown, both the outer arc surface joint 13 and the inner arc surface joint 14 include symmetrically arranged fixing blocks 1 , and the fixing blocks 1 have a rectangular parallelepiped structure. An anchor bar 12 is perforated on the fixing block 1 along a direction perpendicular to the end su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com