Detachable steel tube section construction method used for freezing method construction in tunnel contact channel

A technology of communication channel and construction method, applied in the field of steel pipe sheet structure construction, can solve problems such as affecting the safety of tunnel structures, and achieve the effects of reducing adverse effects, weakening stress concentration effects, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below in conjunction with the accompanying drawings.

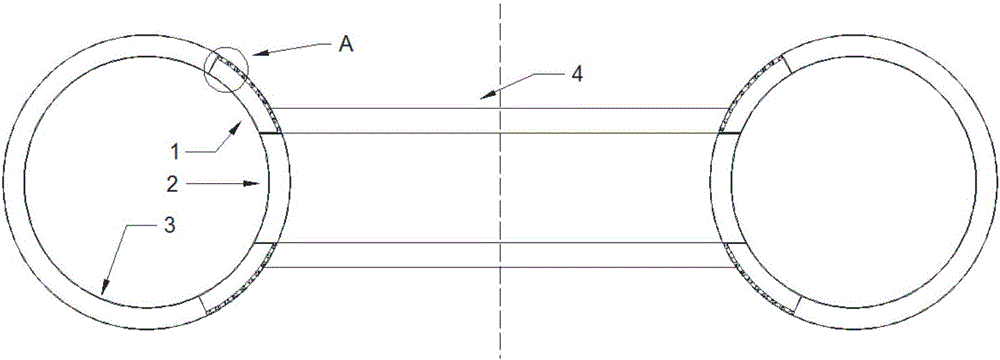

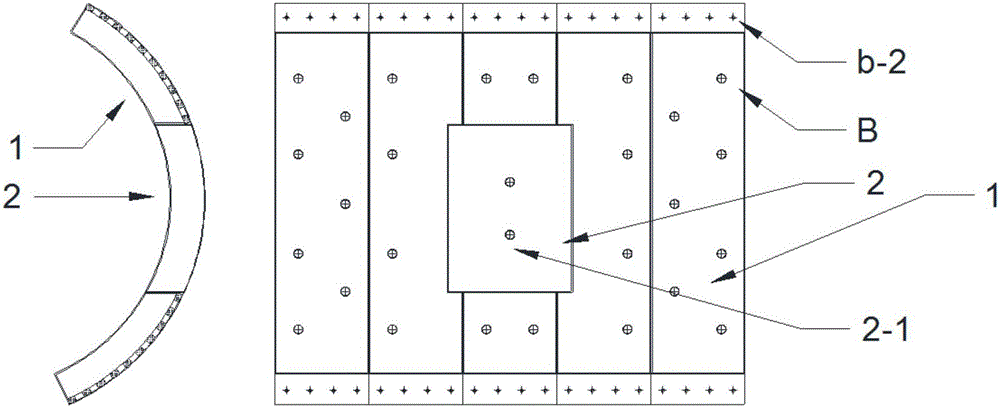

[0023] Such as figure 1 As shown, the present invention provides a detachable steel pipe segment suitable for the freezing method construction at the tunnel communication passage, including a non-detachable part 1 and a detachable part 2 .

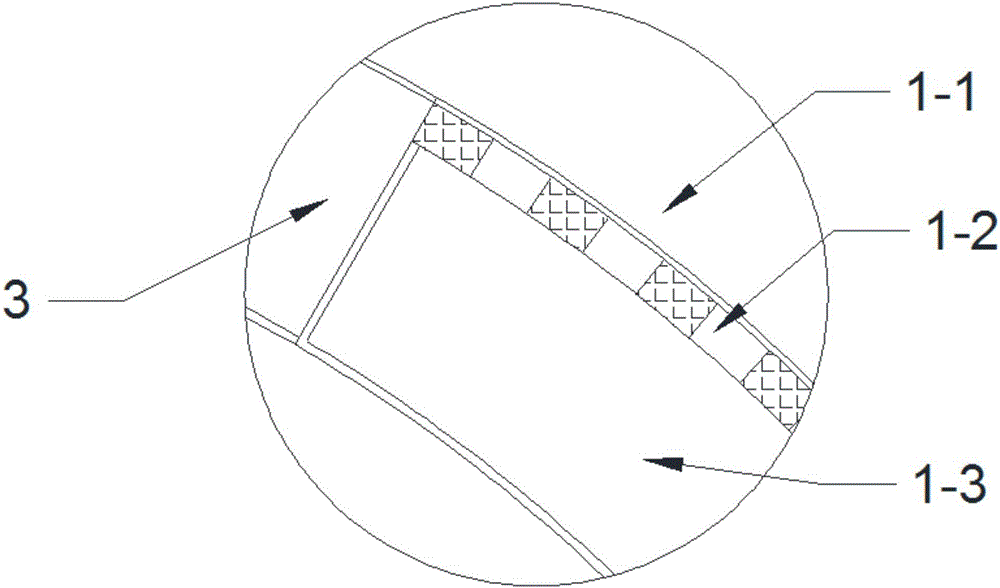

[0024] Such as image 3 As shown, the non-detachable part 1 includes an outer thin steel plate 1-1, a flexible transition layer 1-2 and an inner steel structural segment 1-3. During specific construction, the outer thin steel plate 1-1 is a 6mm steel plate; the flexible transition layer 1-2 is a thin rubber cushion layer, and the mesh of the same specification is evenly distributed on the rubber cushion layer, and penetrates the thin rubber cushion layer; the inner steel structure Segments 1-3 can be designed according to ordinary steel pipe segments. It should be emphasized that the cross-sectional area of the mesh is less t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com