Rolling heating process for stainless steel for soldering

A heating method, stainless steel technology, applied in the field of rolling and heating of stainless steel for welding, can solve the problems of low yield, achieve stable yield, reduce stress concentration effect, and improve thermoplasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

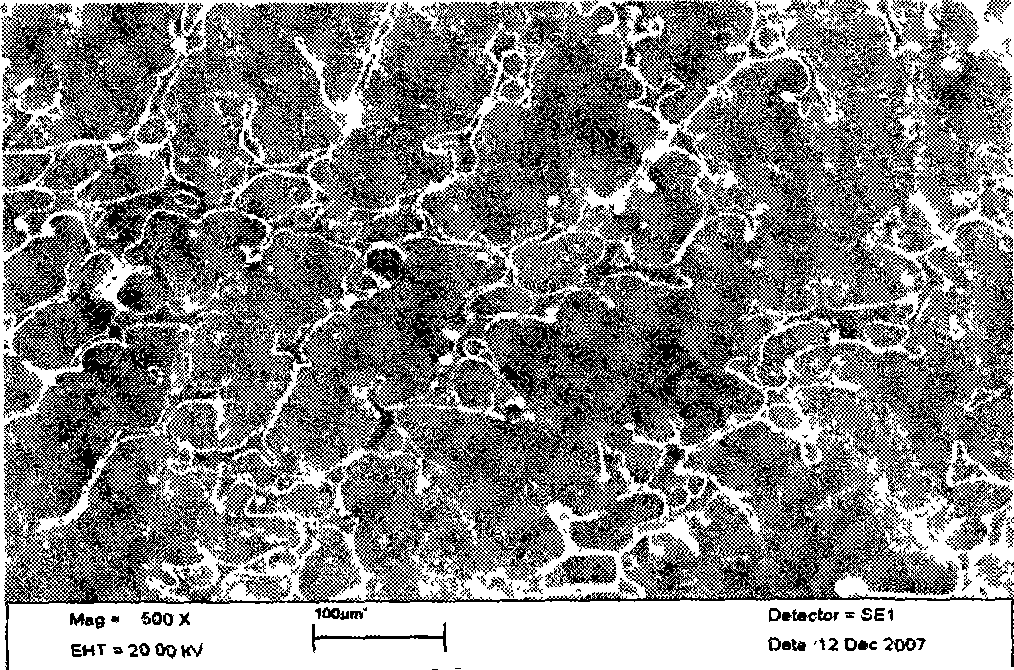

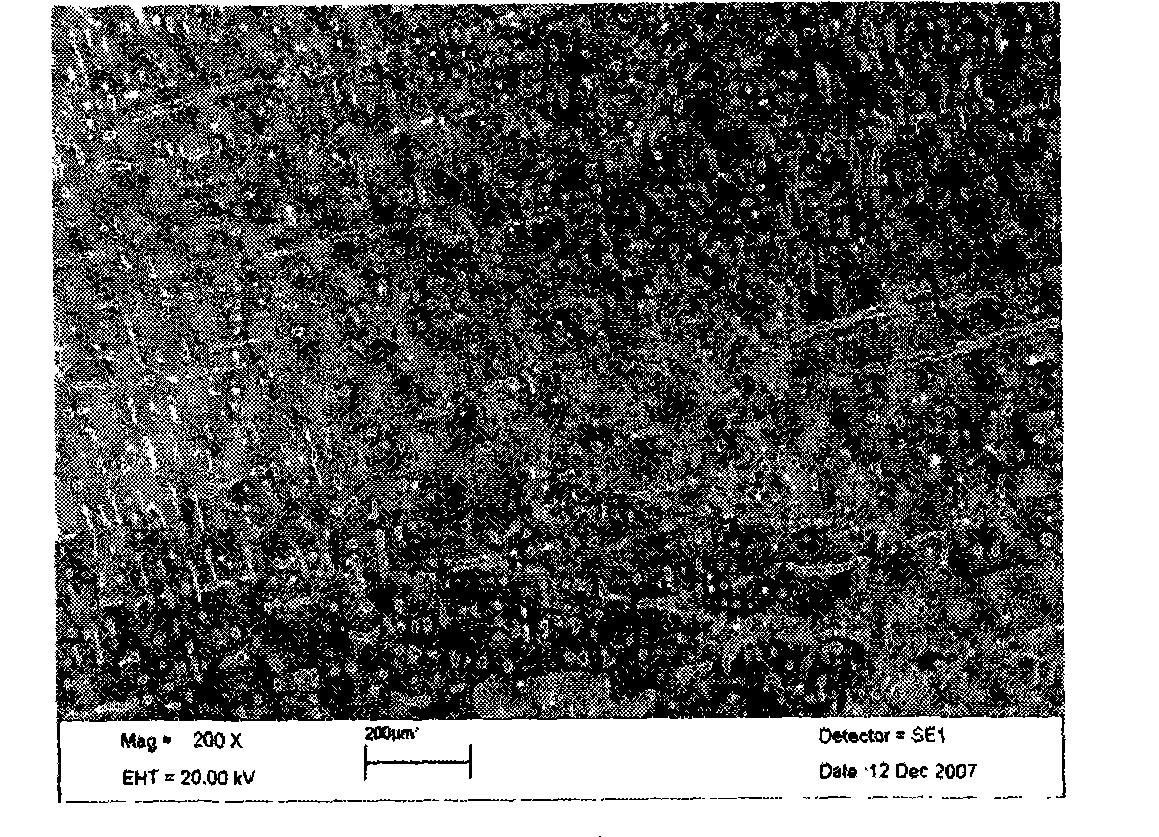

Image

Examples

Embodiment 1

[0024] The chemical composition (weight percentage) of the EQ309L stainless steel billet in this embodiment is: C: 0.025% Si: 0.70% Mn: 2.10% P: 0.025% S: 0.010% Cr: 23.10% Ni: 13.00% N: 0.06% The rest are Fe and inevitable impurities.

[0025] This embodiment of the rolling heating method of EQ309L stainless steel is the following sequential steps

[0026] (1) The first heating: The EQ309L stainless steel billet is heated in a step-by-step continuous heating furnace, and the continuous casting billet is heated to 1100 ° C for 180 minutes, and the EQ309L stainless steel billet is cooled to room temperature after leaving the heating furnace.

[0027] (2) Second heating: After cooling, the EQ309L continuous casting billet is put into the step-by-step continuous heating furnace again for heating, and the continuous casting billet is heated to 1250°C for 180 minutes, and then rolled out of the heating furnace.

[0028] (3) Rolling: The continuous casting billet after being releas...

Embodiment 2

[0030] The chemical composition (weight percent) of the EQ309L stainless steel billet of the present embodiment is:

[0031] C: 0.020% Si: 0.75% Mn: 2.30% P: 0.020% S: 0.005% Cr: 23.20% Ni: 12.80% N: 0.05% The rest are Fe and inevitable impurities.

[0032] The rolling heating method embodiment of this EQ309L stainless steel is the following sequential steps:

[0033] (1) The first heating: The EQ309L stainless steel billet is heated in a step-by-step continuous heating furnace, and the continuous casting billet is heated to 1130 ° C for 200 minutes, and the EQ309L stainless steel billet is cooled to room temperature after leaving the heating furnace.

[0034] (2) Second heating: The cooled EQ309L continuous casting billet is put back into the step-by-step continuous heating furnace, and the continuous casting billet is heated to 1220°C for 220 minutes, and then rolled out of the heating furnace.

[0035] (3) Rolling: The continuous casting billet after being released from th...

Embodiment 3

[0037] The chemical composition (weight percent) of the EQ309L stainless steel billet of the present embodiment is:

[0038] C: 0.018% Si: 0.75% Mn: 2.250% P: 0.017% S: 0.008% Cr: 23.250% Ni: 13.50% N: 0.07% The rest are Fe and inevitable impurities.

[0039] The rolling heating method embodiment of this EQ309L stainless steel is the following sequential steps:

[0040] (1) The first heating: The EQ309L stainless steel billet is heated to 1150°C in a walking continuous heating furnace for 180 minutes, and the EQ309L stainless steel billet is cooled to room temperature after leaving the heating furnace.

[0041] (2) Second heating: After cooling, the EQ309L continuous casting billet is put back into the walking continuous heating furnace, and the continuous casting billet is heated to 1240°C for 190 minutes, and then rolled out of the heating furnace.

[0042] (3) Rolling: The continuous casting billet after being released from the furnace is sent to the hot plate rolling mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com