Functional admixture for treating desulfurized gypsum with high chloride ion content as well as preparation method and application of functional admixture

A technology for desulfurization gypsum and ion content, applied in the field of building materials, can solve problems such as limited curing capacity and difficulty in dealing with desulfurization gypsum, achieve the effect of reducing industrial costs, good application prospects, and improving the curing efficiency of chloride ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

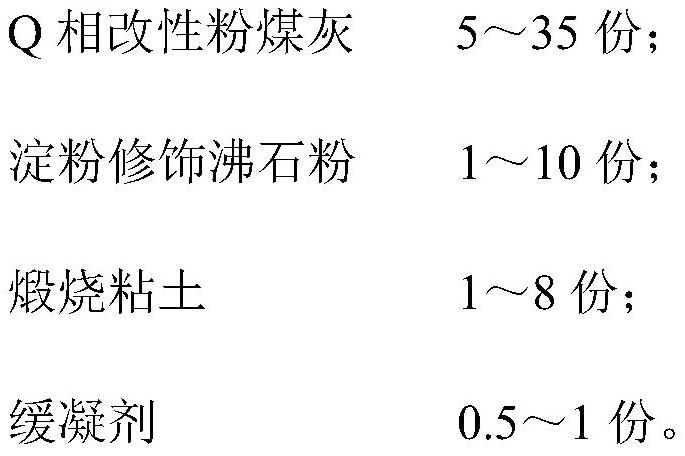

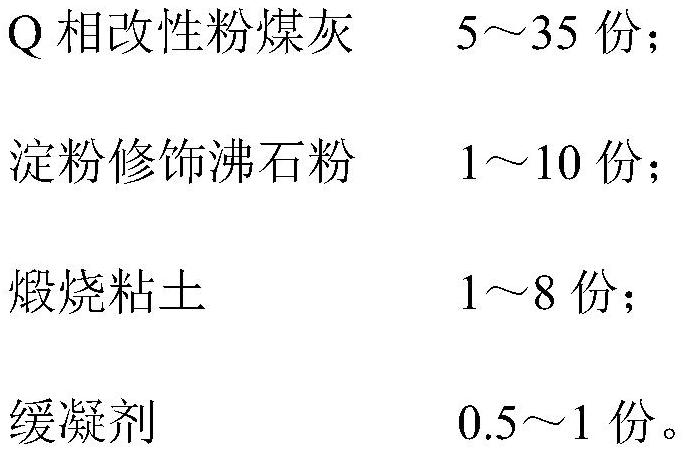

[0047] 7 parts of Q-phase modified fly ash, 3 parts of starch-modified zeolite powder, 2 parts of calcined clay, and 0.5 part of retarder.

[0048] Among them, Q phase modified fly ash is to control the mass fraction of Q phase in the range of 65%, mix with excited fly ash in the ball mill at a speed of 500rpm for 150min, and the excited fly ash is fly ash passing through 6mol / L The sodium hydroxide solution was excited for 180min and washed with water to a product with a pH of 8.

[0049] Starch-modified zeolite powder is mixed with modified zeolite powder and modified starch with a water content of 40% in a mixer with a rotation speed of 200rpm for 240min, wherein the mass fraction of modified zeolite powder is 97% of the mixture, and then dried Can do it. Modified zeolite powder is obtained by calcining natural zeolite powder at 300°C and washing with water to remove organic matter. The specific surface area of modified zeolite powder is not less than 100m 2 / g.

[005...

Embodiment 2

[0054] 11 parts of Q-phase modified fly ash, 5 parts of starch-modified zeolite powder, 3 parts of calcined clay, and 0.6 part of retarder. The source of each component is the same as in Example 1.

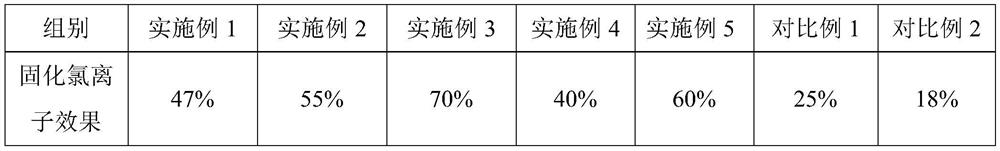

[0055] Mix the above-mentioned mineral admixture with the plaster made from flue gas desulfurization gypsum evenly, and prepare the gypsum slurry according to the water consumption of the standard consistency. The slurry is poured into a steel mold of 20×20×20mm for molding. After the mold is removed, it is naturally cured to the specified age. The obtained gypsum is qualified gypsum that meets the national standard GB / T 37785 third-grade desulfurization gypsum 600ppm. Refer to the national standard method to test the detected content of chloride ions, and the results are shown in Table 1 below.

Embodiment 3

[0057] 15 parts of Q-phase modified fly ash, 7 parts of starch-modified zeolite powder, 4 parts of calcined clay, and 0.7 parts of retarder. The source of each component is the same as in Example 1.

[0058] Mix the above-mentioned mineral admixture with the plaster made from flue gas desulfurization gypsum evenly, and prepare the gypsum slurry according to the water consumption of the standard consistency. The slurry is poured into a steel mold of 20×20×20mm for molding. After the mold is removed, it is naturally cured to the specified age. The obtained gypsum is qualified gypsum that meets the national standard GB / T 37785 third-grade desulfurization gypsum 600ppm. Refer to the national standard method to test the detected content of chloride ions, and the results are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com