Shank tool

A chisel and chisel head technology, applied in roads, manufacturing tools, road repairs, etc., to achieve the effect of small friction and wear, reliable surface pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

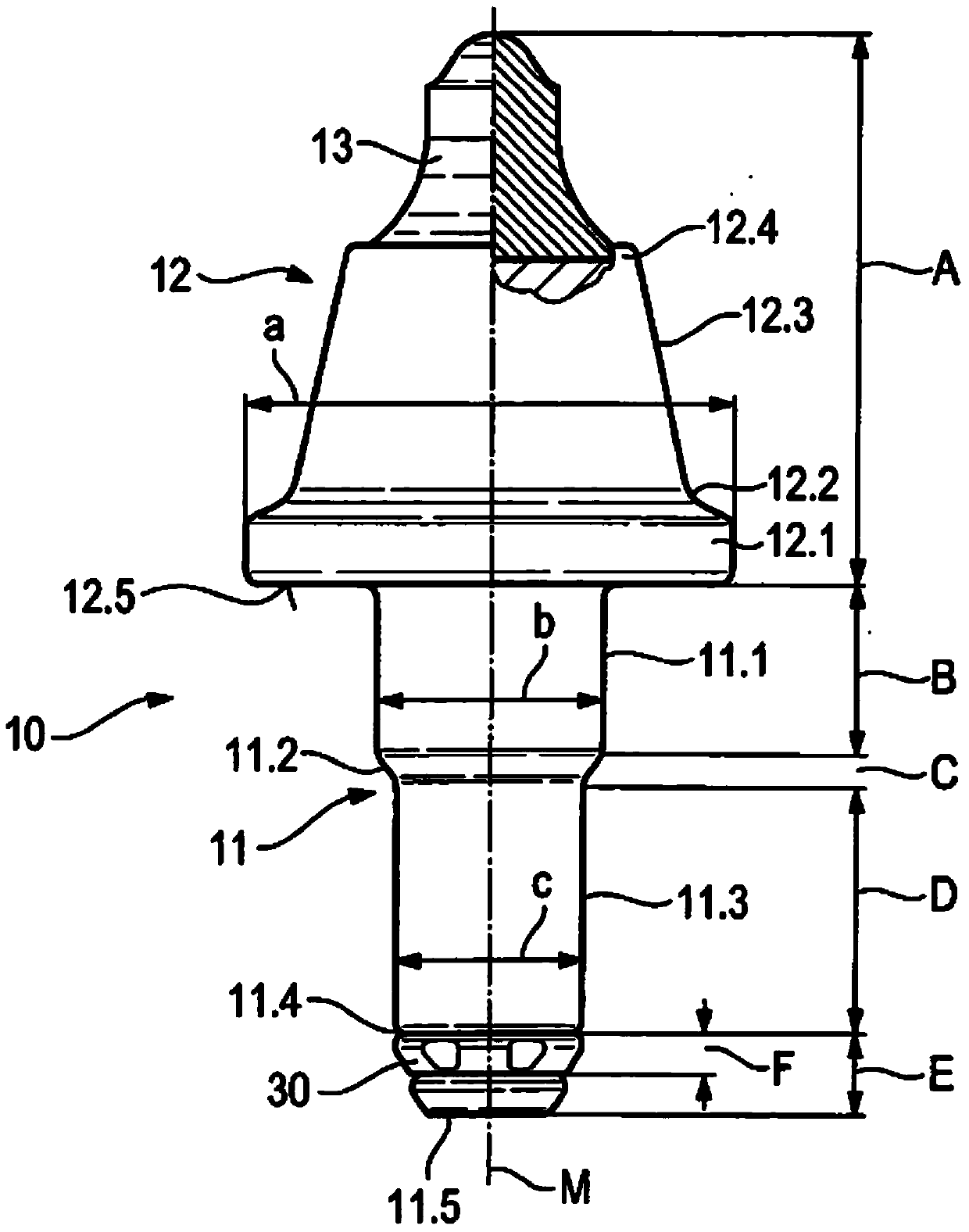

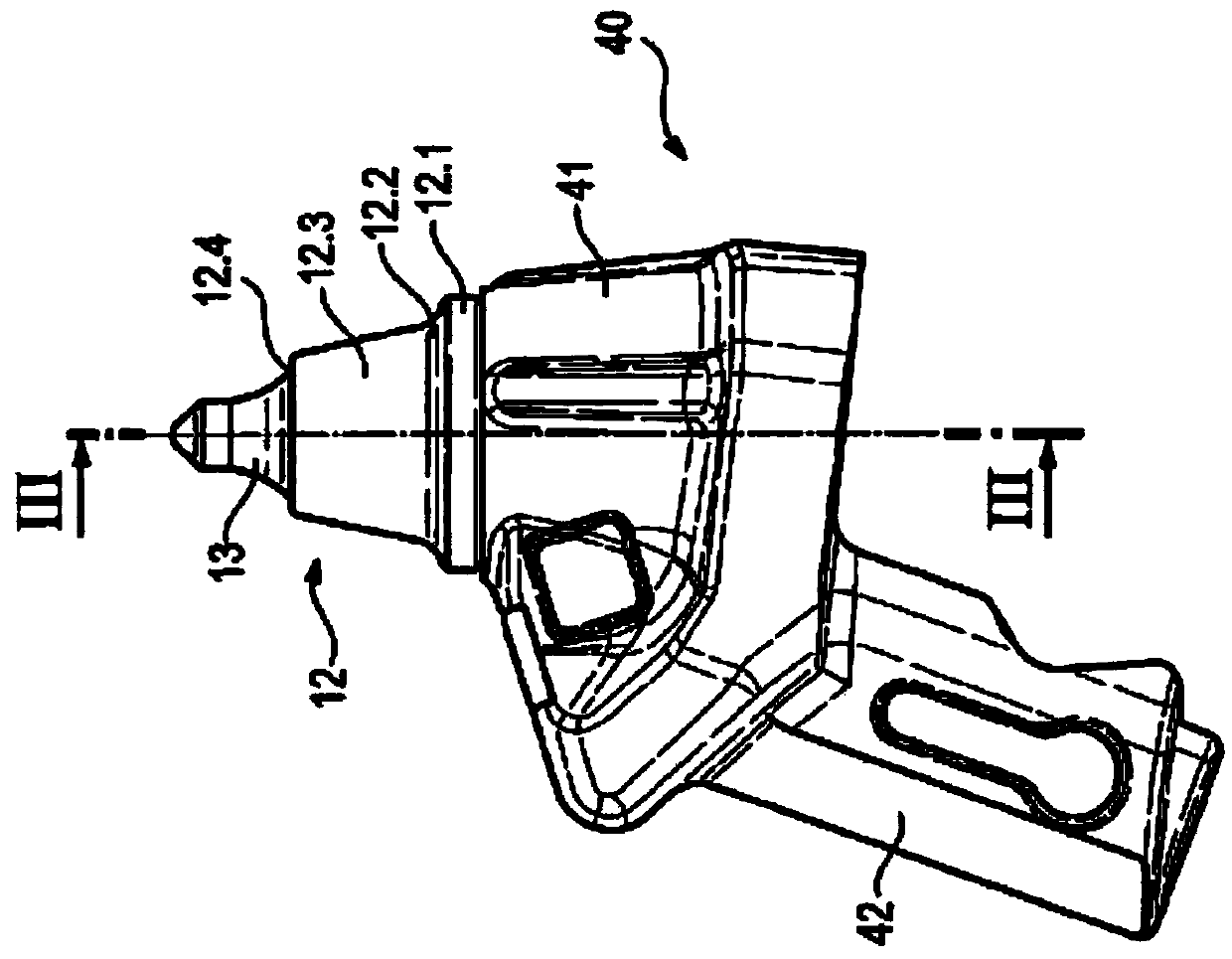

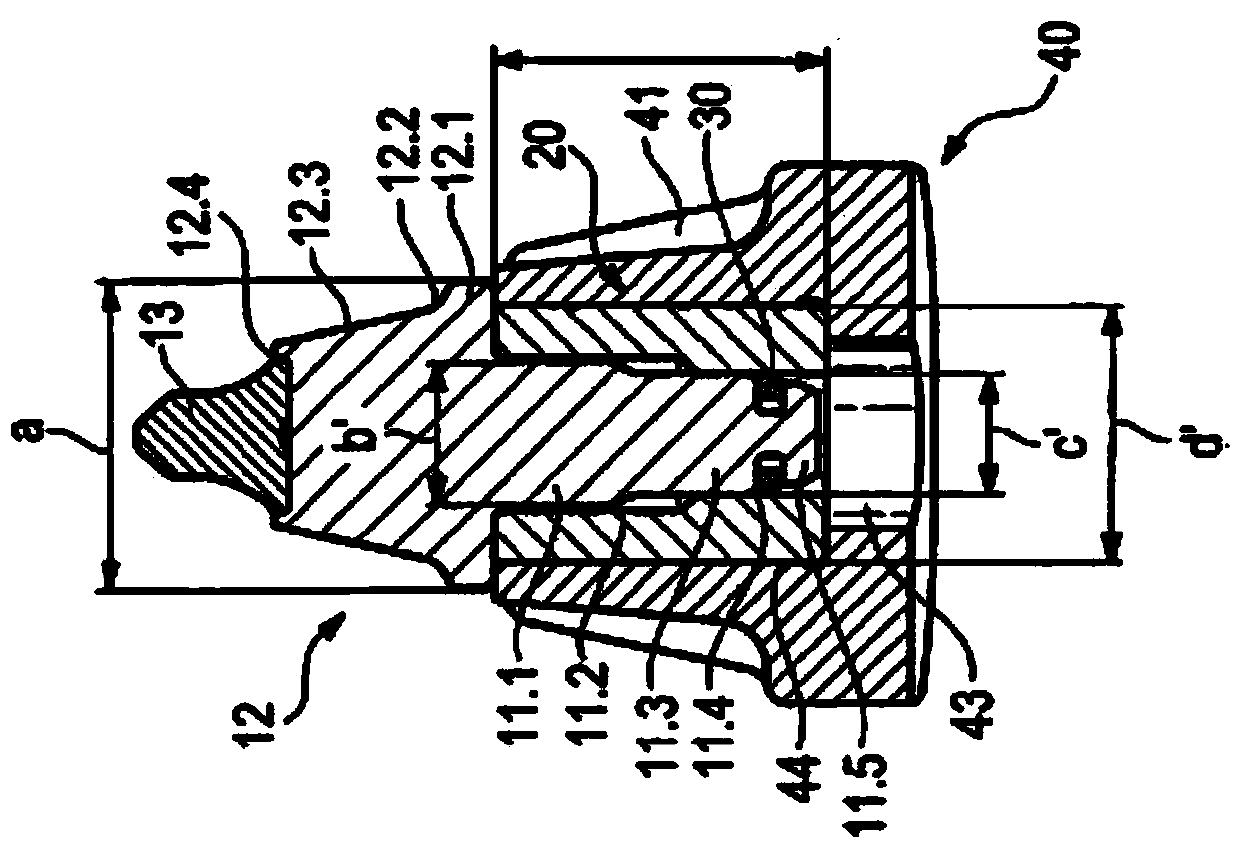

[0039] figure 1 Shown is a shank chisel 10 with a chisel shank 11 and a chisel head 12 formed on it. The chisel shank 11 is designed as a multi-stage shank and has a first cylindrical section 11.1 which transitions via a frustoconical transition section 11.2 into a second cylindrical section 11.3 in the region of the second cylindrical section 11.3 A safety receiver 11.4 in the form of an annular groove is provided in the middle. The safety receptacle 11.4 is delimited at the end by a collar 11.5. The first cylindrical section 11.1 is directly connected to the support surface 12.5 of the chisel head 12 via a circular transition or alternatively via a frusto-conical transition section. A stress-optimized contour shape has proven to be advantageous when using a frustoconical transition section with a cone angle of 45° and an extension of less than 4 mm in the direction of the central longitudinal axis M of the chisel shank 11 . The support surface 12.5 is annular here and is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com