Shock absorber chassis and a sightseeing vehicle composed of the shock absorber chassis and the sightseeing vehicle

A vehicle chassis and chassis frame technology, which is applied to vehicle components, elastic suspension, suspension, etc., can solve the problems of unilateral wear of friction wheels, inconvenient adjustment, and uneven force, so as to reduce serious unilateral wear and cushion. The effect is stable and the performance is ensured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

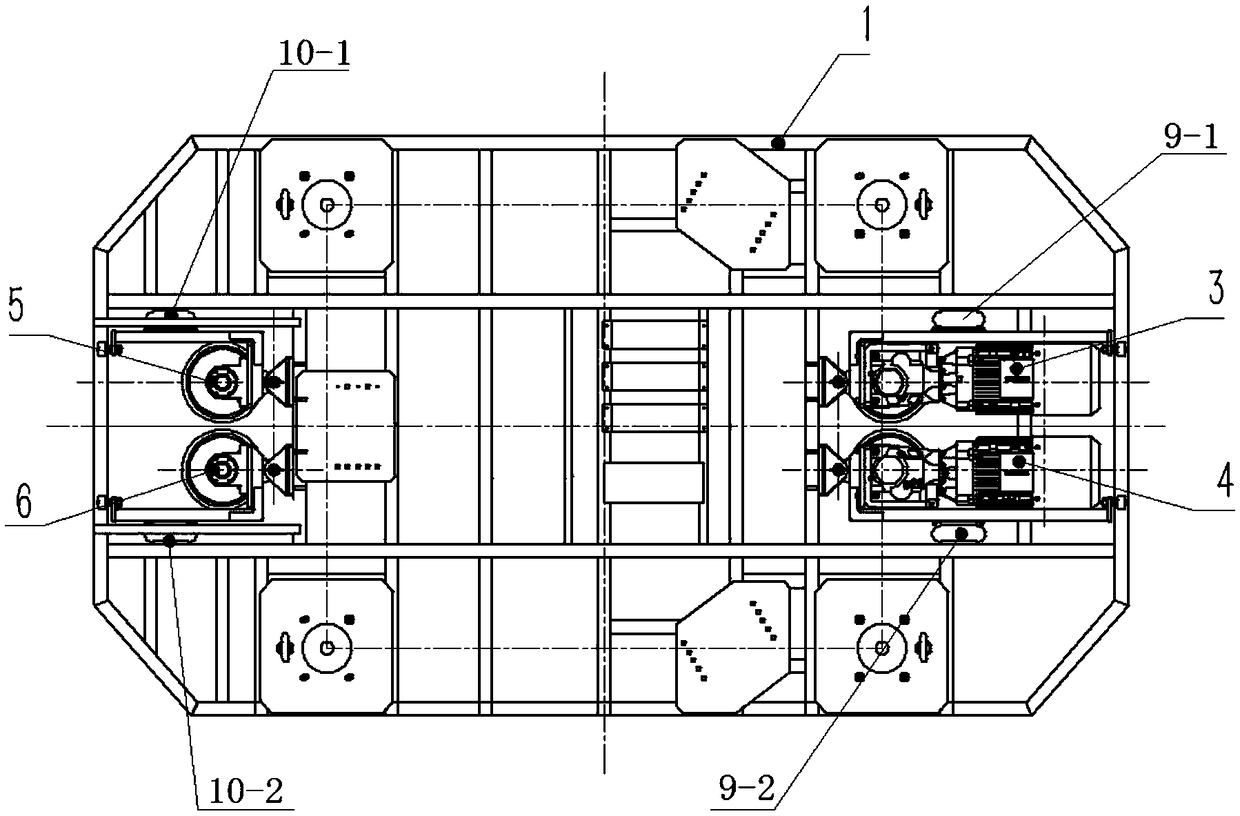

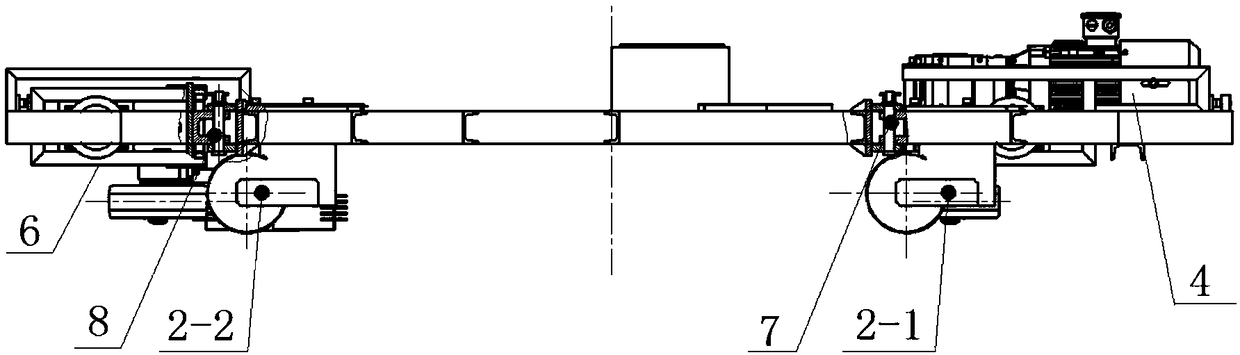

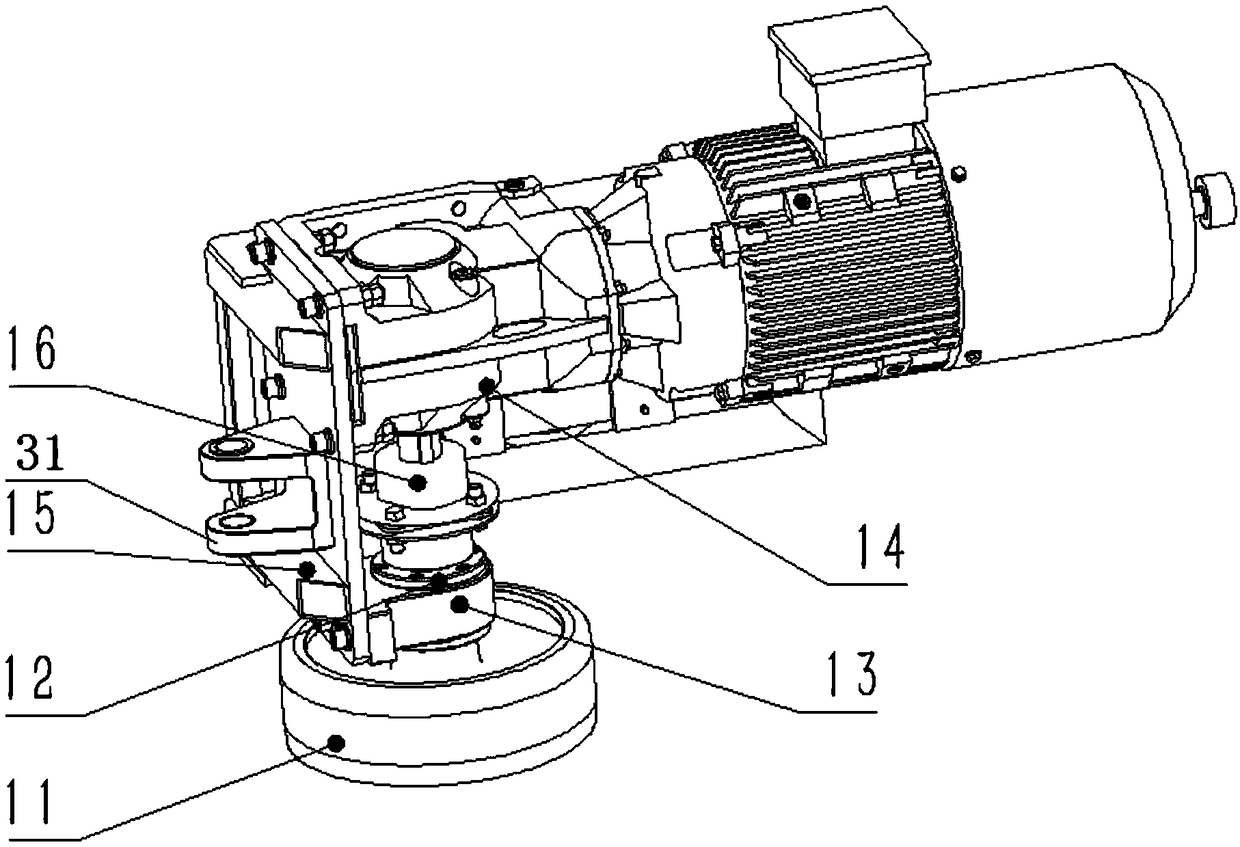

[0031] Specific implementation mode one: please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the specific embodiment adopts the following technical scheme, which includes a chassis frame 1, a shock absorbing support mechanism, a left drive assembly 3, a right drive assembly 4, a left limit mechanism 5 and a right limit mechanism 6, and the shock absorber support mechanism includes The first airbag 9-1, the second airbag 9-2, the third airbag 10-1, the fourth airbag 10-2, the first damping wheel 2-1 and the second damping wheel 2-2, the left drive The assembly 3 and the right drive assembly 4 are horizontally arranged at one end of the chassis frame 1, the left drive assembly 3 is connected with the chassis frame 1 through the first airbag 9-1, and the right drive assembly 4 is connected with the chassis frame 1 through the second airbag 9-2. Connected, the bottom of the left drive assembly 3 and the bottom of the right drive assembly 4 are each prov...

specific Embodiment approach 2

[0044] Specific implementation method two: please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , the specific embodiment adopts the following technical solutions, and the specific embodiment adopts the following technical solutions, which include a shock absorbing vehicle chassis 27, a six-degree-of-freedom motion mechanism 28, a rotating mechanism 29 and a cabin 30, and the described shock absorbing vehicle chassis 27, The six-degree-of-freedom motion mechanism 28, the rotating mechanism 29, and the cabin 30 are arranged sequentially from bottom to top. The bottom is connected, and the top of the rotating mechanism 29 is hinged with the bottom of the cabin 30;

[0045] The shock-absorbing vehicle chassis 27 includes a chassis frame 1, a shock-absorbing support mechanism, a left drive assembly 3, a right drive assembly 4, a left limiting mechanism 5 and a right limiting mechanism 6, and the shock-absorbing supporting mechanism includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com