Heelless shoes

A technology without heels and soles, which is applied in the field of shoe manufacturing, can solve the problems of reduced service life, risk-prone, and poor stability of shoes, and achieve the effects of prolonging service life, good walking stability, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

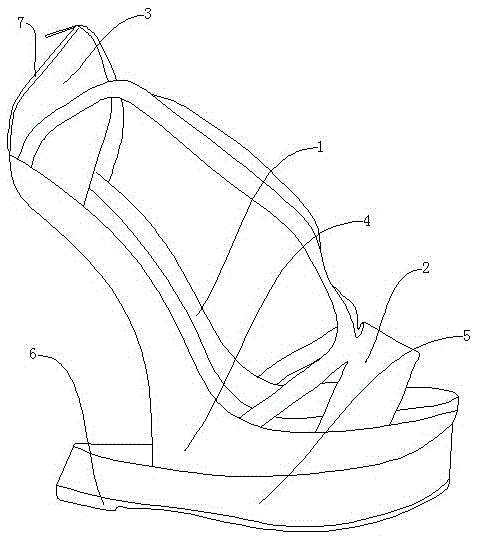

[0012] Such as figure 1 As shown, the heelless shoes described in this embodiment include a sole 1 and a vamp 2, the front end of the sole 1 is horizontal, the middle and rear ends of the sole 1 are inclined upwards, and a rear wall 3 is provided at the rear end of the sole 1. The lower surface of the sole 1 is attached with a shoe sole holder 4, the front end of the shoe sole holder 4 is horizontal, and the middle and rear end of the shoe sole holder 4 is inclined upwards, and the front end bottom of the shoe sole holder 4 is provided with a walking pad 5.

[0013] The longitudinal length of the walking pad 5 is greater than half of the longitudinal length of the sole 1 and less than the longitudinal length of the sole 1 .

[0014] The bottom of the walking mat 5 is provided with a wear-resistant rubber layer 6 .

[0015] The rear wall 3 relative to the rearmost end of the sole 1 may have a disconnected structure, which is connected as a whole by a slide fastener 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com