Method for preparing functional ultraviolet-resistant polyester staple fiber from waste renewable polyester bottle chips

A polyester staple fiber, anti-ultraviolet technology, applied in fiber processing, stretch spinning, filament forming processing, etc., to achieve good economic and social benefits, solve environmental protection problems, and low prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

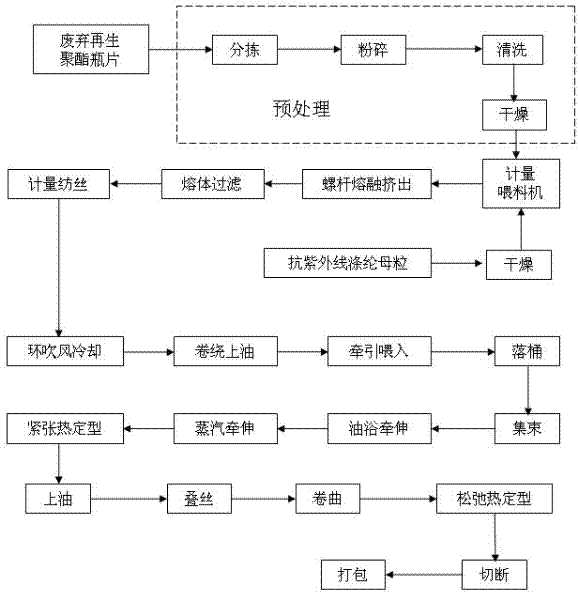

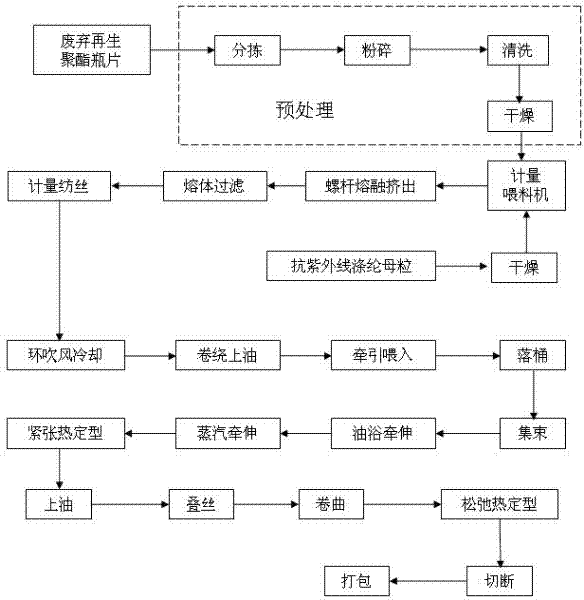

[0022] A method for preparing functional anti-ultraviolet polyester staple fibers from waste recycled polyester bottle flakes according to the present invention, see figure 1 , Firstly, pretreatment and drying are carried out on the recycled waste recycled polyester bottle flakes. Pretreatment includes a series of raw material preparations such as sorting, crushing, and cleaning waste recycled PET bottle flakes, and then put the cleaned bottle flakes into the drum vacuum dryer. After the materials are put in, the drum clamps Pass 3-5kg of steam or heat-conducting oil through the sleeve, and rotate the drum at a low speed at the same time, keep the temperature at 130-160°C, and start the vacuum pump to evacuate at the same time, the vacuum degree is kept at 0.06-0.10Mpa, and the drying time is 8-12 hours. The moisture content of the bottle flakes is controlled below 100PPm.

[0023] At the same time, the anti-ultraviolet polyester masterbatch is dried. The anti-ultraviolet po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| number of curls | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com