Dynamically vulcanized styrene thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer, styrene-based technology, applied in the field of dynamically vulcanized styrene-based thermoplastic elastomer and its preparation, can solve the problems of restricting further use, mechanical properties, resistance to compression set, wear resistance, odor residue, etc. , to achieve the effects of safe use, compression set resistance, improved wear resistance, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

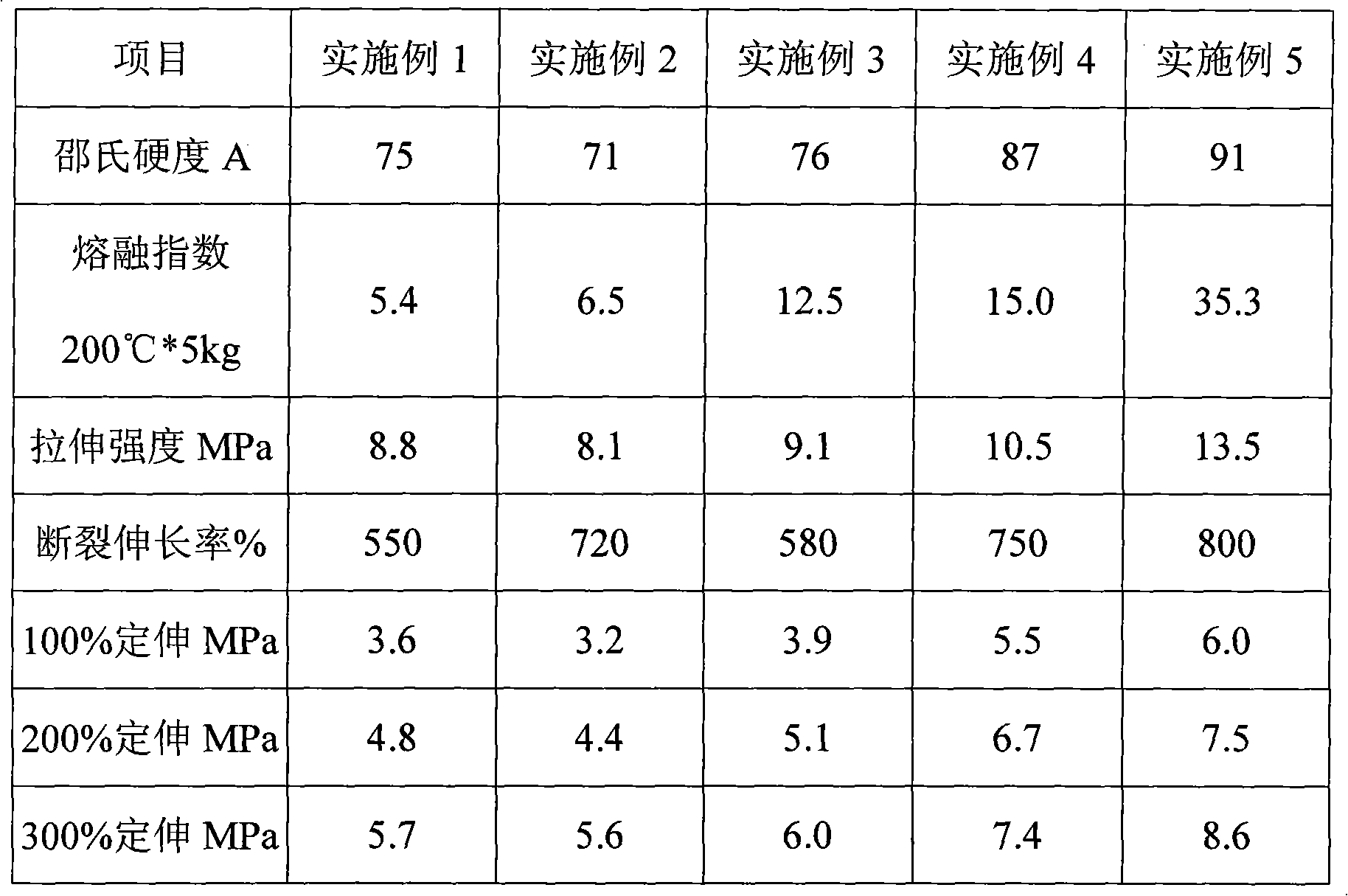

Examples

Embodiment 1

[0042] A preparation method of a dynamically vulcanized styrene-based thermoplastic elastomer, the method comprising the following steps:

[0043] (1) according to the following components of weight content (wt%):

[0044] SEBS1651 35

[0045] 100# white oil 39

[0046] PPY600 19

[0047] Talc powder (1500 mesh) 6.7

[0048] Antioxidant 1010 0.14

[0049] Cross-linking agent 0.1

[0050] Auxiliary cross-linking agent TAIC 0.06;

[0051] (2) Add each component into the high-speed mixer, mix at high speed for 1-3 minutes, and the spindle speed of the mixer is 700r / min;

[0052] (3) Put the well-mixed mixture into a twin-screw extruder with an aspect ratio greater than 36:1 to carry out dynamic vulcanization reaction in a molten state, extrude, and granulate. The processing temperature is 190-230°C. The rotational speed of the twin-screw extruder was 300 rpm to obtain a dynamically vulcanized styrene thermoplastic elastomer.

Embodiment 2

[0054] A preparation method of a dynamically vulcanized styrene-based thermoplastic elastomer, the method comprising the following steps:

[0055] (1) according to the following components of weight content (wt%):

[0056] SEBS1651 34.8

[0057]100# white oil 39

[0058] PPM800E 19.9

[0059] Talc powder (1500 mesh) 6

[0060] Antioxidant 1010 0.14

[0061] Cross-linking agent 0.1

[0062] Auxiliary cross-linking agent TAIC 0.06;

[0063] Steps (2) to (3) are the same as in Example 1.

Embodiment 3

[0065] A preparation method of a dynamically vulcanized styrene-based thermoplastic elastomer, the method comprising the following steps:

[0066] (1) according to the following components of weight content (wt%):

[0067] SEBS1654 34.8

[0068] 100# white oil 39

[0069] PPY600 19.9

[0070] Talc powder (1500 mesh) 6

[0071] Antioxidant 1010 0.14

[0072] Cross-linking agent 0.1

[0073] Auxiliary cross-linking agent TAIC 0.06

[0074] Steps (2) to (3) are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com