High-toughness waste rubber asphalt and preparation method thereof

A technology of waste rubber and waste rubber powder, which is applied in building components, building insulation materials, construction, etc., can solve problems such as market promotion resistance, and achieve the effects of solving high temperature environment, improving viscosity and toughness, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

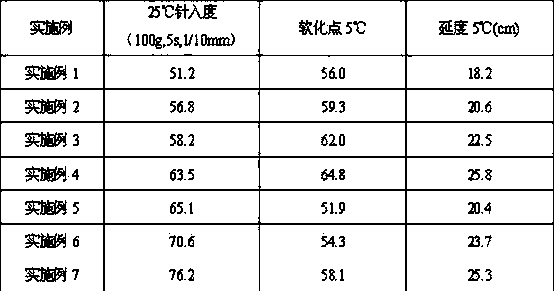

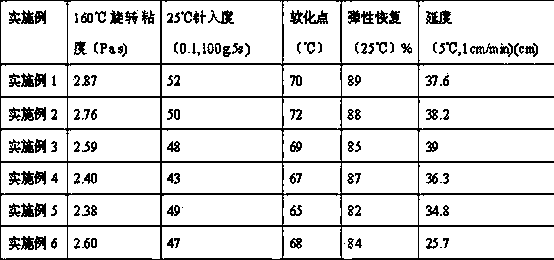

Examples

Embodiment 1

[0036] 1. Prepare materials according to the following proportions by weight:

[0037] Base bitumen (Road No. 70 bitumen): 89.5 copies Waste rubber powder (60 mesh): 10.0 copies Activator (thiuram disulfide): 0.20 servings Nano toughening agent (nano carbon black): 0.20 servings Cross-linking agent (ethylene glycol bisacryloyl ester): 0.10 parts

[0038] 2. Preparation of high toughness rubber modified asphalt

[0039] Put all the above base asphalt in a high-temperature tank, heat it to 150°C and melt it, then pump it through a metering device and send it to a processing reaction kettle with heating and heat preservation functions; at the same time, put all the above waste rubber powder, activator, nano The toughening agent and cross-linking agent are transported to the processing reactor through the gas metering and conveying device, and the matrix asphalt, waste rubber powder, activator, nano-toughening agent, and cross-linking ag...

Embodiment 2

[0044] 1. Prepare materials according to the following proportions by weight:

[0045] Base asphalt (No. 90 road asphalt): 84.07 copies Waste rubber powder (30 mesh): 15.0 servings Activator (diethanolamine): 0.30 servings Nano Toughener (Nano Calcium Carbonate) 0.45 servings Crosslinking agent (melamine formaldehyde resin): 0.18 servings

[0046] 2. Preparation of waste rubber solid modified asphalt

[0047] Put all the above base asphalt in a high-temperature tank, heat it to 160°C and melt it, then pump it through a metering device and send it to a processing reaction kettle with heating and heat preservation functions; at the same time, put all the above waste rubber powder, activator, nano The toughening agent and cross-linking agent are transported to the processing reactor through the gas metering and conveying device, and the matrix asphalt, waste rubber powder, activator, nano-toughening agent, and cross-linking agent ar...

Embodiment 3

[0052] 1. Prepare materials according to the following proportions by weight:

[0053] Base asphalt (No. 90 road asphalt): 79.34 copies Waste rubber powder (90 mesh): 20.0 servings Activator T (thiuram disulfide) 0.30 servings Nano Toughener (Nano Boron Nitride) 0.20 servings Cross-linking agent (acetate acrylic resin emulsion): 0.16 servings

[0054] 2. Preparation of waste rubber solid modified asphalt

[0055] Put all the above base asphalt in a high-temperature tank, heat it to 155°C and melt it, then pump it through a metering device and send it to a processing reaction kettle with heating and heat preservation functions; at the same time, put all the above waste rubber powder, activator, nano The toughening agent and cross-linking agent are transported to the processing reactor through the gas metering and conveying device, and the matrix asphalt, waste rubber powder, activator, nano-toughening agent, and cross-linking agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com