Manufacturing method of artificial core with crevices for simulated leaking stoppage experiment

A technology of artificial core and production method, which is applied in the field of drilling leak prevention and oil well operation, can solve the problems of not absorbing water, etc., achieve the effects of not easy to break, simple manufacturing process, and beneficial to oil well mining operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

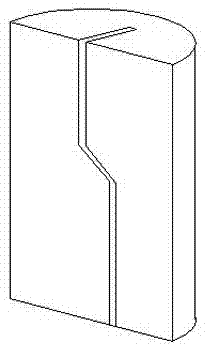

[0015] 1. Make a paraffin plate with curved surfaces on both sides of the reinforcement:

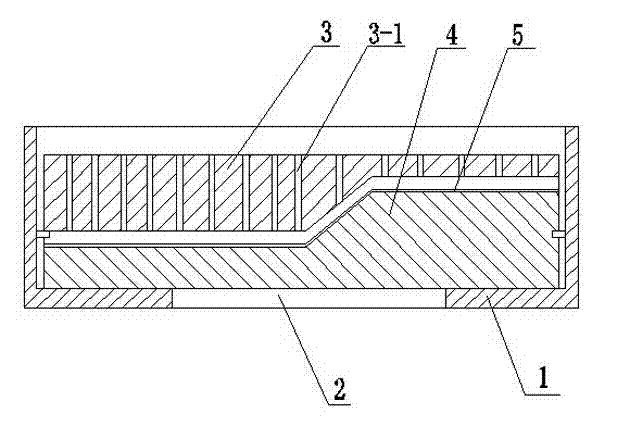

[0016] 1. Make a metal box 1 with a length of 60 cm, a width of 6 cm, and a height of 8 cm, and one side of the long end is open. A long groove 2 with a width of 1 cm and a length of 50 cm is opened at the bottom of the box 1 along the center to both ends.

[0017] 2. Make two metal plates or wooden boards 3, 4 with a length of 60 cm, a width of 6 cm, and a thickness of 2 cm. One side is a plane, and the other side is a curved surface. Through hole 3-1.

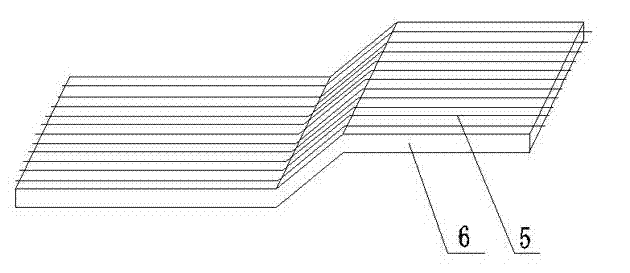

[0018] 3. Put the two curved panels 3 and 4 facing each other into the metal box 1, put the curved panel 3 with the through hole 3-1 on top, and put the curved panel 4 without holes on the bottom. Place a number of thin lines 5 with a length of at least 60cm on the curved surface along its length direction, so that the distance between the two boards is equal to the width of the design crack, and fix the upper board firmly, as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com