Low-melting point and high-crystallization temperature PET copolyester, its preparation method and application

A high-crystal, copolyester technology, applied in the field of PET copolyester, can solve the problems of high cost of polymer nucleating agent crustacean liquid crystal, inconsistency with actual production, affecting PET performance, etc., to improve processing and forming performance, good bending Modulus, effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

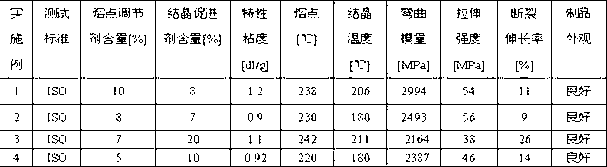

Examples

Embodiment 1

[0030] Put 3.74kg of terephthalic acid, 0.42kg of isophthalic acid, and 2.02kg of ethylene glycol into the esterification kettle, and carry out the esterification reaction at 0.2~0.4MPa and 260°C; when the amount of water distilled from the esterification reaches After the target value, it is transferred to the polycondensation kettle, and the catalyst is added with 0.5g antimony trioxide, 0.24g tetrabutyl titanate, stabilizer 0.72g triphenyl phosphate TPP, 1.2g antioxidant 1010 and 332g crystallization accelerator Polyethylene glycol 10000, polymerized under normal compression for 45 minutes, gradually reduced the pressure in the reactor to 60Pa within 45 minutes, and at the same time raised the temperature to 275°C, polycondensed for 2 hours under high vacuum; when the intrinsic viscosity reached the target value, filled Inject nitrogen, press out the resin from the reaction kettle under nitrogen pressure, and obtain copolyester slices through water cooling, drawing, and pell...

Embodiment 2

[0032] Put 4.98kg of terephthalic acid, 2.41kg of ethylene glycol, and 0.28kg of 1,4-butanediol into the esterification axe, and carry out the esterification reaction at 0.2~0.4MPa and 260°C; After the output reaches the target value, transfer it to the polycondensation kettle, add catalyst 0.6g antimony trioxide, 0.32g tetrabutyl titanate, stabilizer 1.05g triphenyl phosphate TPP, 0.95g antioxidant 1010 and crystallization Accelerator 348g polyethylene glycol 4000, after 60 minutes of normal compression polymerization, gradually reduce the pressure in the reactor to 60Pa within 45 minutes, and at the same time raise the temperature to 275 ° C, high vacuum polycondensation for 2 hours; when the intrinsic viscosity reaches the target After the value is filled, nitrogen is filled, and under nitrogen pressure, the resin is extruded from the reaction kettle, and the copolyester chips are obtained by water cooling, drawing, and pelletizing; then the chips are dried and pre-crystalli...

Embodiment 3

[0034] 4.64kg terephthalic acid, 0.35kg isophthalic acid, 2.41kg ethylene glycol, 996g polytetrahydrofuran 2000, 1.16g antimony trioxide catalyst, 0.26g tetrabutyl titanate, 1.05g triphenyl phosphate stabilizer Put TPP and 0.95g antioxidant 1010 into the esterification axe, carry out esterification reaction at 0.2~0.4MPa, 260°C, when the distilled amount of water generated by esterification reaches the target value, transfer it to the polycondensation kettle , after 60 minutes of normal compression polymerization at 260°C, gradually reduce the pressure in the reactor to 60Pa within 45 minutes, and at the same time raise the temperature to 270°C, and perform high vacuum polycondensation for 2 hours; when the intrinsic viscosity reaches the target value, fill in Nitrogen, under the pressure of nitrogen, the resin is pressed out from the reactor, and the copolyester slices are obtained by water cooling, drawing, and pelletizing; then the slices are dried and pre-crystallized at 13...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com