Weather-resistant environment-friendly vinyl resin

A vinyl resin, weather-resistant technology, applied in the polymer field, can solve the problems of insufficient weather resistance, vinyl resin weather resistance can not meet the needs and other problems, to achieve the effect of good flexural modulus and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

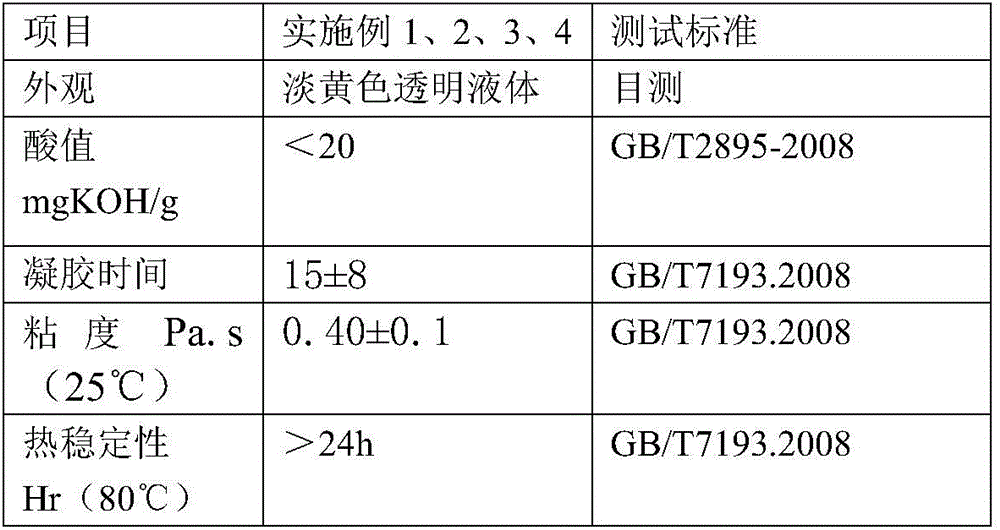

Image

Examples

Embodiment 1

[0022] A weather-resistant environment-friendly vinyl resin, its formula is: bisphenol F epoxy resin 43kg, silicone modified epoxy resin 8kg, styrene modified alkyd resin 12kg, methacrylic acid 18kg, acrylic acid 11kg, rich Maleic acid 7kg, maleic anhydride 10kg, ethyltriphenylphosphine bromide 1kg, hydroquinone 0.5kg, styrene 36kg, flame retardant 5kg, weather modifier 2kg; carbomer is Carbopol ETD 2020 ;

[0023] The weathering modifier is formulated in the following proportions: 8kg citraconic anhydride, 5kg carbomer, 3kg polydimethylsiloxane, 4kg ethylene glycol, 0.5kg 4,4'-diaminodiphenylsulfone, cis Butenedioic acid 5kg, propylene glycol methyl ether acetate 3kg, compounding agent 8kg, compounding agent is triethanolamine 3kg, 1,4-butyrolactone 2.5kg, palm kernel oil fatty acid 2.5kg.

Embodiment 2

[0025] A weather-resistant environment-friendly vinyl resin, its formula is: bisphenol F epoxy resin 45kg, silicone modified epoxy resin 5kg, styrene modified alkyd resin 15kg, methacrylic acid 15kg, acrylic acid 15kg, rich 5kg of malic acid, 12kg of maleic anhydride, 0.5kg of ethyltriphenylphosphine bromide, 0.8kg of hydroquinone, 33kg of styrene, 5kg of flame retardant, and 8kg of weather resistance modifier. Carbopol for Carbopol ETD 2020.

[0026] The weathering modifier is formulated in the following proportions: 10kg citraconic anhydride, 3kg carbomer, 5kg polydimethylsiloxane, 2kg ethylene glycol, 2kg 4,4'-diaminodiphenyl sulfone, butadiene 3kg of olefinic acid, 4kg of propylene glycol methyl ether acetate, 5kg of compounding agent, 1.5kg of compounding agent is triethanolamine, 2kg of 1,4-butyrolactone, 1.5kg of palm kernel oil fatty acid.

Embodiment 3

[0028] On the basis of Example 1, add 1 kg of self-curing agent, which is a mixture of xylylenediamine and acrylonitrile, and the ratio of the two is 2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com