Fuel assembly for isotope production of nuclear reactor

A technology for nuclear reactors and fuel assemblies, which is applied to the assembly of reactor fuel materials, fuel elements, and fuel elements, etc., can solve the problems affecting the safety of nuclear power plants, affecting the power generation and economy of nuclear power plants, and increasing the power peak factor of local fuel rods, etc. It can reduce the influence of reactivity and power peak factor, improve the processing and forming performance, and reduce the difficulty of separation and purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

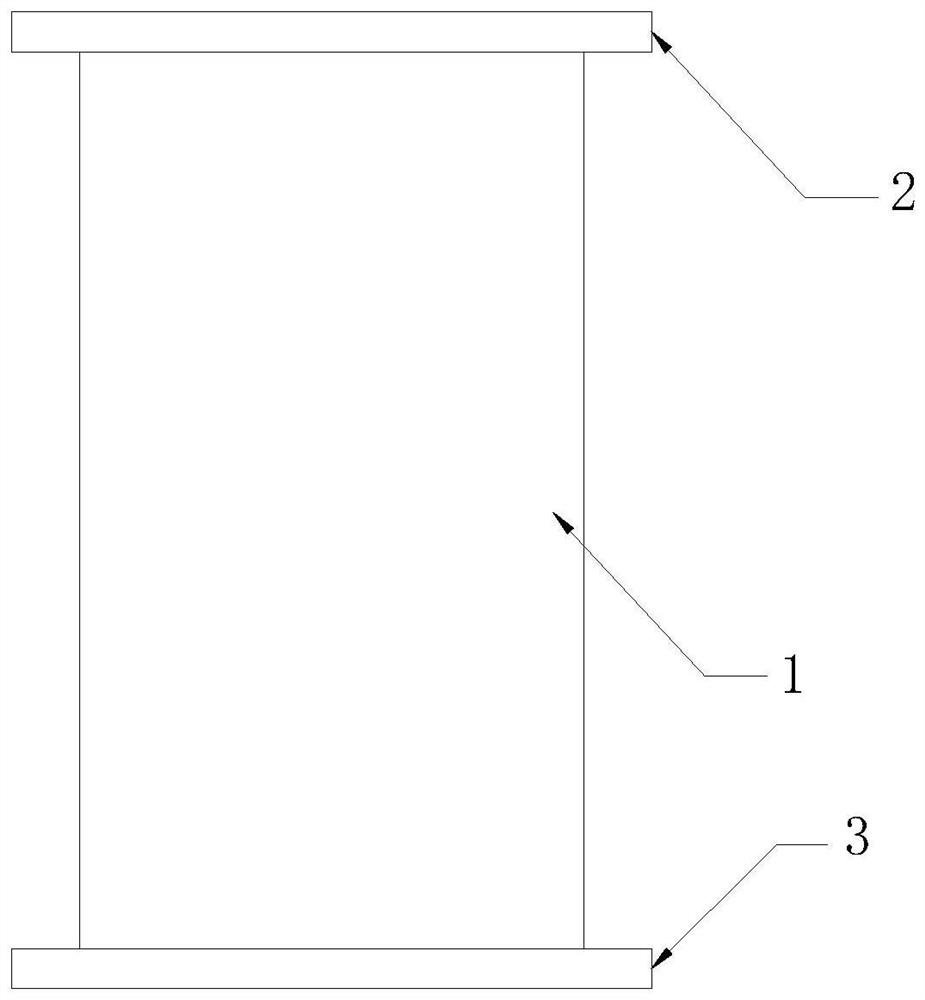

[0030] The radioisotopic material NpO 2 An annular base material 5 core block with a wall thickness of 3 mm is prepared, the base material 5 has an outer diameter of 12 mm and an inner diameter of 5.7 mm, and is packed into the outer cladding shell 1 of zirconium alloy. Base metal 5 pellets made of NpO 2 It is prepared by mixing with Zr powder, the volume fraction of Zr powder is not less than 30%, the density after compression molding is about 80%, and the density of sintering can reach more than 95%.

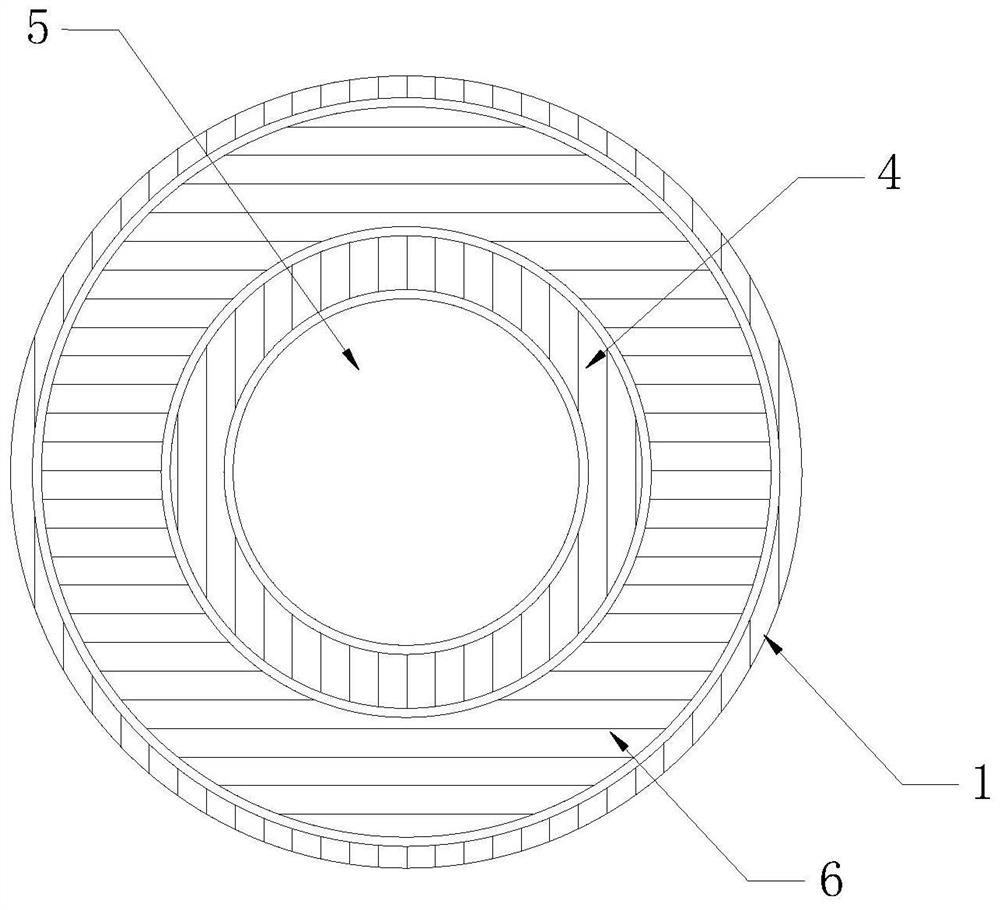

[0031] Will UO 2 Pellet 6 was prepared as a solid pellet with a diameter of 5.5 mm, and the enrichment of U-235 was increased to 25.8%. The prepared solid UO 2 The pellet 6 is placed on the radioactive isotope material NpO 2 In the ring-shaped parent material 5 core blocks, the specific form is as image 3 shown.

[0032] Base metal 5 and UO 2 The pellets 6 are independent of each other, and the isotope base material NpO can be directly dismantled in the nuclear power p...

Embodiment 2

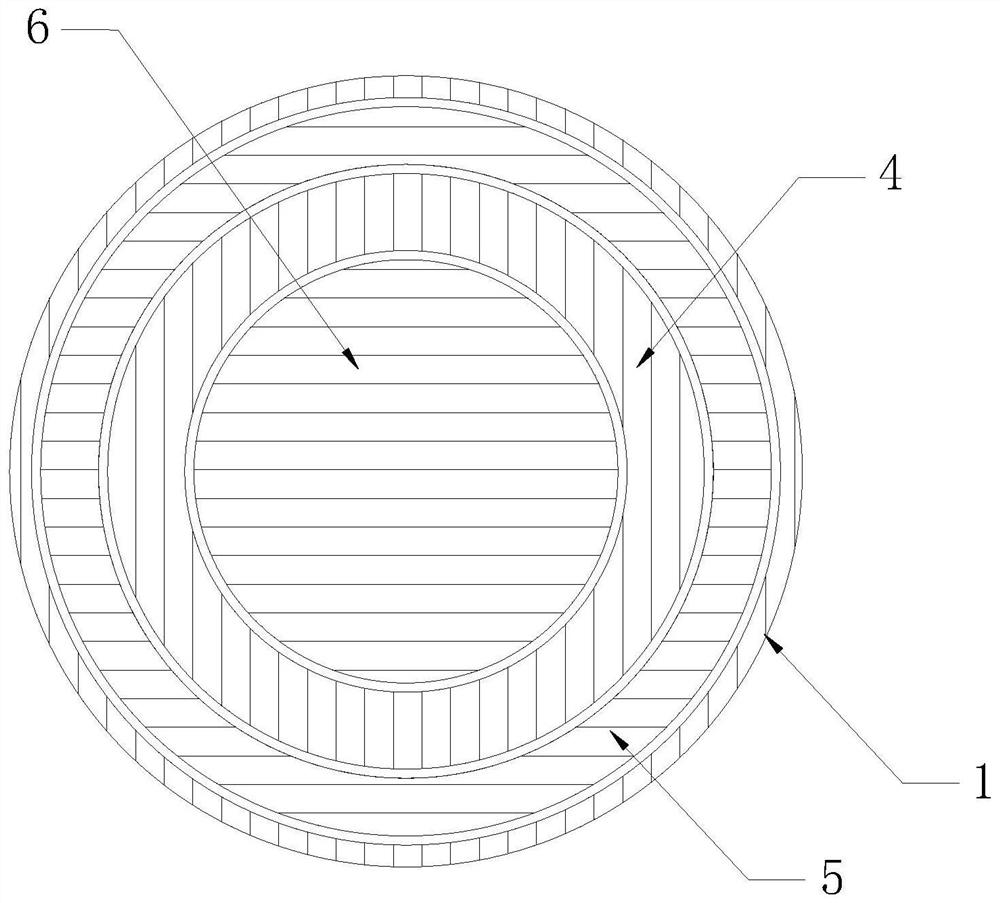

[0034] Ring UO 2 The design of the core block 6, select the annular UO with a wall thickness of 2.5mm 2 The pellet 6 has an outer diameter of 12 mm and an inner diameter of 7 mm, and the enrichment degree of U-235 is increased to 30%, and is loaded into the outer shell 1 .

[0035] NPO 2 Base material 5 is made of NpO 2 It is mixed with SiC powder to prepare a base material 5 with a diameter of 5.5mm, the volume fraction of SiC powder is not less than 30%, the compactness after compression molding is about 80%, and the compactness of sintering can reach more than 95%. NpO 2 The base metal 5 is put into the zirconium alloy inner cladding 4 to prepare thin-diameter rods. The outer diameter of the inner cladding 4 is 6.85mm and the inner diameter is 5.7mm.

[0036] The prepared NpO 2 The base metal 5 is placed on the annular UO 2 Pellet 6, as in figure 2 shown. UO 2 and NpO 2 independent of each other and can be directly separated.

Embodiment 3

[0038] The radioisotope material TeO 2 The base material 5 is prepared as an annular pellet with a wall thickness of 2mm, the outer diameter of the pellet is 11.2mm, and the inner diameter is 7.2mm, which is loaded into the outer shell 1 of zirconium alloy. Base metal 5 pellets made of TeO 2 It is prepared by mixing with alumina powder, the volume fraction of alumina powder is not less than 40%, the density after compression molding is about 85%, and the density of sintering can reach more than 95%.

[0039] Will UO 2 Pellet 6 was prepared as a solid pellet with a diameter of 5.7mm, and the enrichment of U-235 was increased to 46.7%. Will UO 2 The pellet 6 is put into the zirconium alloy inner cladding 4 to prepare a thin-diameter rod. The zirconium alloy inner cladding is 46.8mm in diameter and 5.7mm in inner diameter. The prepared solid UO 2 The pellet 6 is placed on the radioactive isotope material TeO 2 In the annular core block, the specific form is as image 3 sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com