High-formability magnesium alloy

A formability and magnesium alloy technology, applied in the field of metal material processing, can solve the problems of poor formability and high processing cost of magnesium alloys, and achieve the effect of improving the formability of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

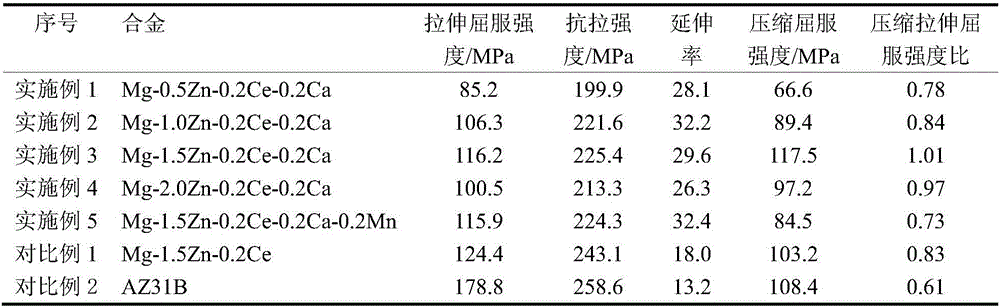

Embodiment 1

[0017] In this embodiment, the magnesium alloy is composed of the following components by mass percentage: Zn0.5%, Ce0.2%, Ca0.2%, unavoidable impurities are about 0.015%, and the rest is Mg.

Embodiment 2

[0019] In this embodiment, the magnesium alloy consists of the following components in terms of mass percentage: 1.0% Zn, 0.2% Ce, 0.2% Ca, about 0.015% of unavoidable impurities, and the rest is Mg.

Embodiment 3

[0021] In this embodiment, the magnesium alloy consists of the following components by mass percentage: Zn 1.5%, Ce 0.2%, Ca 0.2%, unavoidable impurities about 0.015%, and the rest being Mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com