Prestressed Cable Point Curtain Wall Structure and Construction Method

A prestressed and curtain wall technology, applied in the direction of walls, building components, building structures, etc., to achieve the effects of small space, stable overall force, and reduced damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

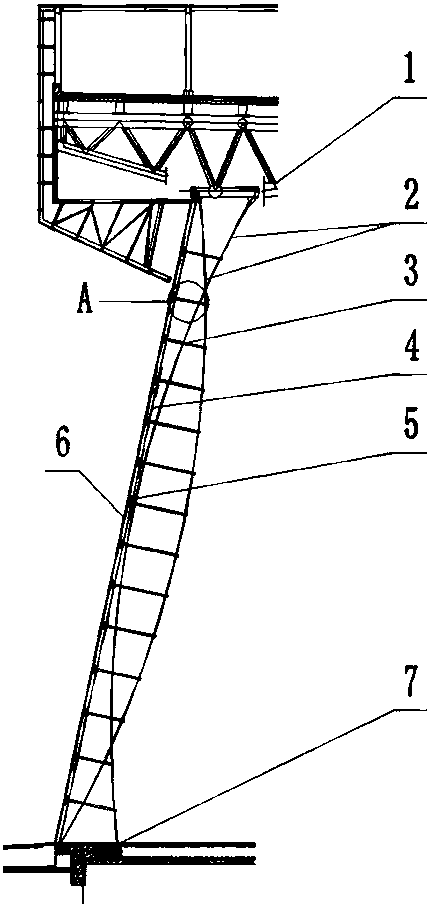

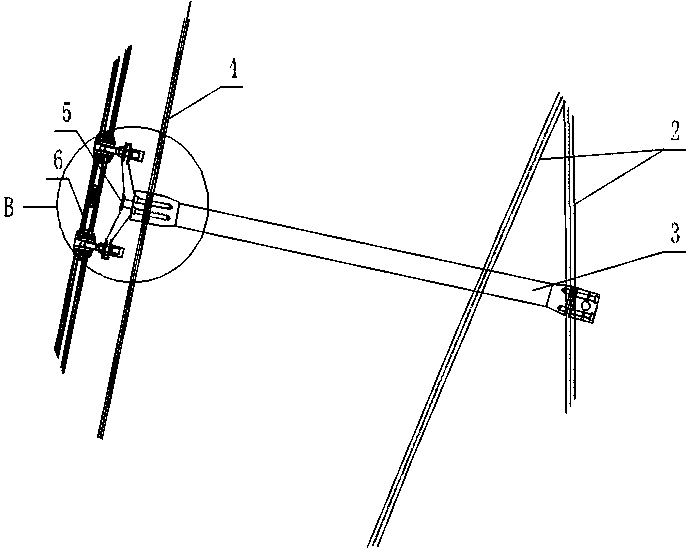

[0039] Such as Figure 1 to Figure 5 As shown, the prestressed cable-point curtain wall structure includes a cable, a strut 3, a connection device 5 and a curtain wall glass 6, and the two ends of the cable are fixed on the truss 1 of the building or on the ground anchor 7. The draglines include two main draglines 2, the number of the struts 3 and the connecting devices 5 are multiple, and the numbers of the struts 3 and the connecting devices 5 are equal;

[0040] The struts 3 are provided with two cable fixing parts, the struts 3 are arranged side by side in a row, and the two main cables 2 pass through the different cable fixing parts on each strut 3 successively, and are located at two The struts 3 between the main cables 2 constrain the main cables 2 into a corrugated or arc shape, and the two main cables 2 cross each other, and the two main cables 2 are both in a tensioned state;

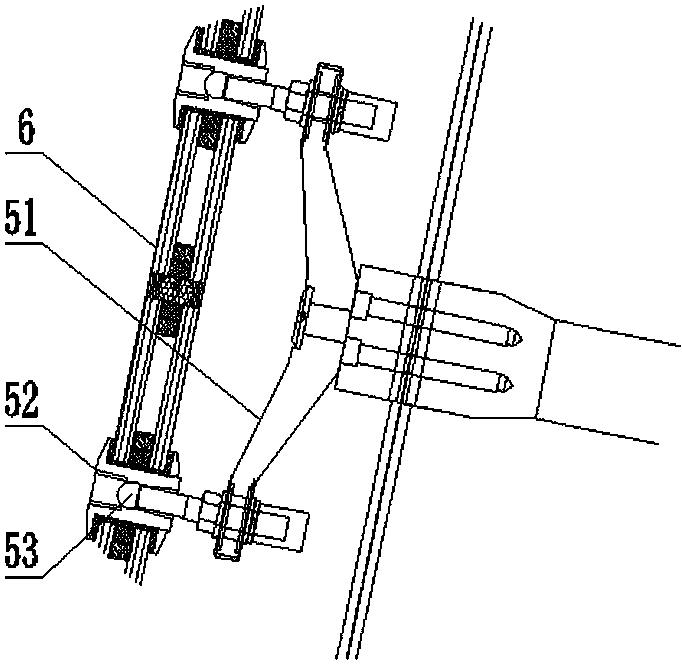

[0041] Each support rod 3 is fixed with a connecting device 5 , and the connecting device...

Embodiment 2

[0046] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 5 As shown, as a specific connection form of the main stay cables 2 on the building, the upper ends of the two main stay cables 2 are fixed on the truss 1 of the building, and the lower ends of the two main stay cables 2 are fixed on the ground anchor 7 Above, the projections of the two main cables 2 toward the side of the curtain wall glass 6 are both straight lines, and the two straight lines coincide, and the struts 3 are perpendicular to the plane where the curtain wall glass 6 is located. The above connection form of the main cable 2 on the building, the gravity of the curtain wall glass 6 support structure composed of the main cable 2, the strut 3 and the connecting device 5 can be balanced by the pulling force on the main cable 2, which can effectively avoid or Reduce the impact of the gravity of the supporting structure of the curtain wall glass 6 on the stress of the ...

Embodiment 3

[0054] This embodiment further defines the present invention on the basis of any one of the technical solutions provided in embodiment 1 or embodiment 2:

[0055] Such as Figure 1 to Figure 5 As shown, in order to facilitate the realization of connecting a large glass curtain wall into a whole, to realize the mutual restraint of the glass support structure of the glass curtain wall, which is beneficial to the stability of the whole, two main cables 2, multiple support rods 3, A plurality of connecting devices 5 form a glass fixing part, and the glass fixing part is multiple, and also includes a plurality of integral cables, and each integral cable has a connection point with the glass fixing part.

[0056] At the same time, this embodiment provides a specific application example. The curtain wall structure is used as the curtain wall of the commodity exhibition center. The total construction area of the commodity exhibition center is 116702.46 square meters, and the main bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com