Environmentally-friendly halogen-free PC/ABS alloy and preparation method thereof

An environmentally friendly and alloy technology, applied in the field of polymer materials, to achieve the effect of good application prospects, excellent processing performance, high flexural strength and flexural modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

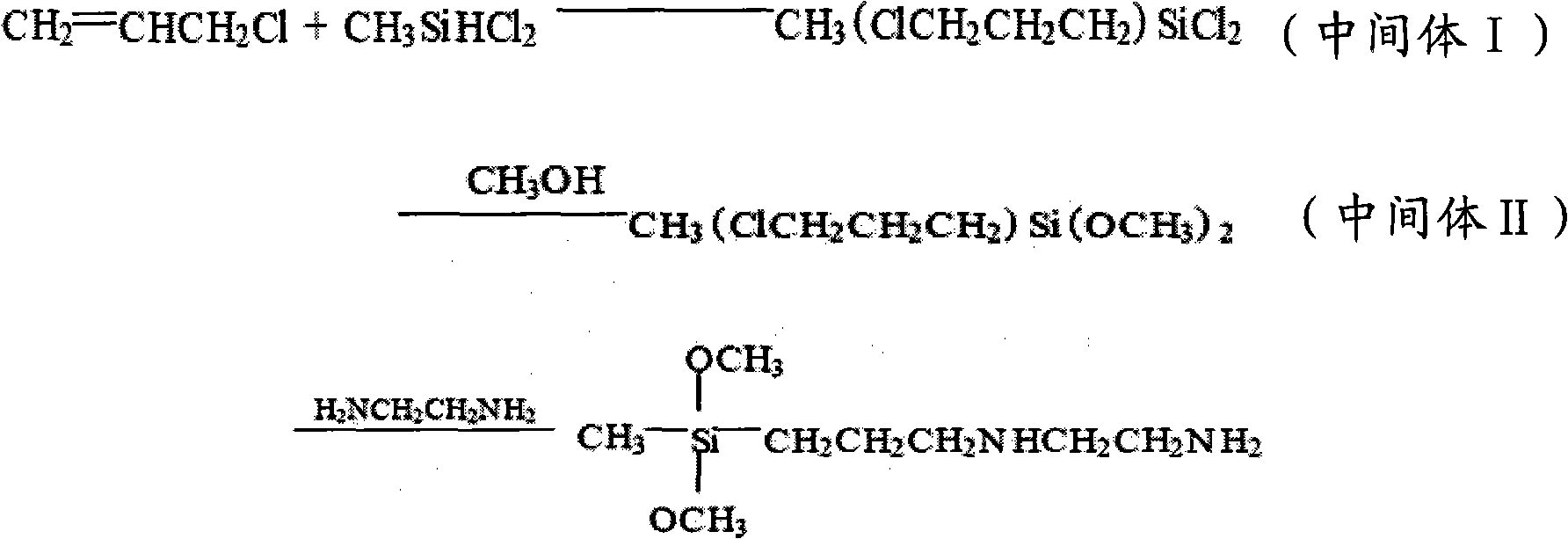

[0029] The preparation method of self-made silane coupling agent:

[0030] Raw material: Methyldichlorosilane: purity 98.2%, Xinghuo Chemical Plant

[0031] Propyl chloride: purity 98.5%, Hunan Yueyang Chemical

[0032] Anhydrous methanol, analytically pure, Beijing Chemical Plant

[0033] Ethylenediamine: analytically pure, Shenyang Xinxing Reagent Factory

[0034] Chloroplatinic acid: chemically pure, Shenyang Keda Reagent Factory

[0035] Composite path:

[0036]

[0037] Basic method: Using methyl dichlorosilane and allyl chloride as raw materials and chloroplatinic acid as a catalyst, an intermediate I was synthesized: methyl (γ-chloropropyl) dichlorosilane, which was combined with Ethylenediamine reacts to give the product.

[0038] Synthesis of Intermediate I: In a 250ml three-neck flask equipped with a thermometer, a constant pressure dropping funnel, and a reflux condenser, add 0.2mol of allyl chloride and chloroplatinic acid solution, and stir electromagnetic...

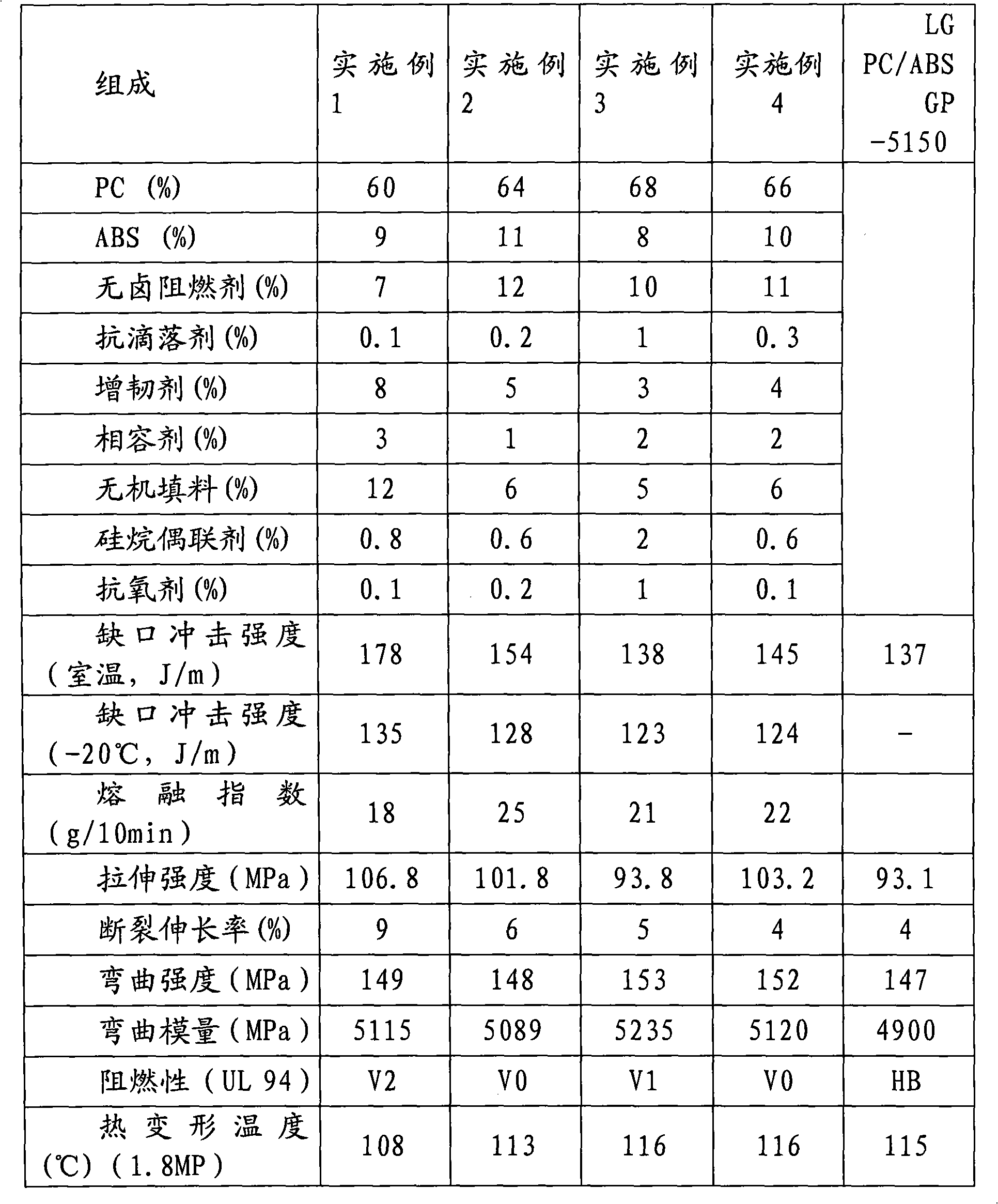

Embodiment 1

[0042] Add 0.8% of silane coupling agent and 12% of 2000 mesh talc powder into a high-speed batch mixer for pre-mixing for 3 minutes, then add 7% of halogen-free flame retardant, 0.1% of flame retardant and anti-dripping agent, 8% of toughening agent, 3% of the compatibilizer and 0.1% of the antioxidant were added together into a high-speed batch mixer and stirred for 5 minutes, and each component was in weight percentage. Then add the baked 60% PC and 9% ABS, and then stir together for 5 minutes for later use. Put the stirred mixture in a twin-screw machine to melt, extrude and granulate. The process conditions are as follows: twin-screw first stage temperature 220-230°C, second-stage temperature 230-240°C, third-stage temperature 240-250°C, mold temperature 60 ~100℃, residence time 1~2 minutes, pressure 10~15MPa.

[0043] In this embodiment, the toughening agent is a core-shell ABS impact modifier with a rubber content of 60-80%. The compatibilizer is ABS grafted malanic a...

Embodiment 2

[0046] Add 0.6% of silane coupling agent and 6% of 2000 mesh calcium carbonate to a high-speed batch mixer for pre-mixing for 3 minutes, then add 12% of halogen-free flame retardant, 0.2% of flame retardant and anti-dripping agent, 5% of toughening agent, Add 1% of compatibilizer and 0.2% of antioxidant together into a high-speed batching mixer and stir for 5 minutes, and each component is in weight percentage. Then add the baked 64% PC and 11% ABS, and then stir together for 5 minutes for later use. Put the stirred mixture in a twin-screw machine to melt, extrude and granulate. The process conditions are as follows: twin-screw first stage temperature 220-230°C, second-stage temperature 230-240°C, third-stage temperature 240-250°C, mold temperature 60 ~100℃, residence time 1~2 minutes, pressure 10~15MPa.

[0047]In this embodiment, the toughening agent is a core-shell ABS impact modifier with a rubber content of 60-80%. The compatibilizer is ABS grafted malanic anhydride wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com