Variable jaw structure protecting helmet

A chin guard and variable technology, applied in helmets, helmet covers, clothing, etc., can solve the problems of weak fit and strength of the chin guard and the main body of the helmet shell, weakening the flexural modulus of the chin guard, and aggravating stress concentration. , to achieve the effect of eliminating the hidden danger of stress concentration, enhancing the flexural modulus and improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

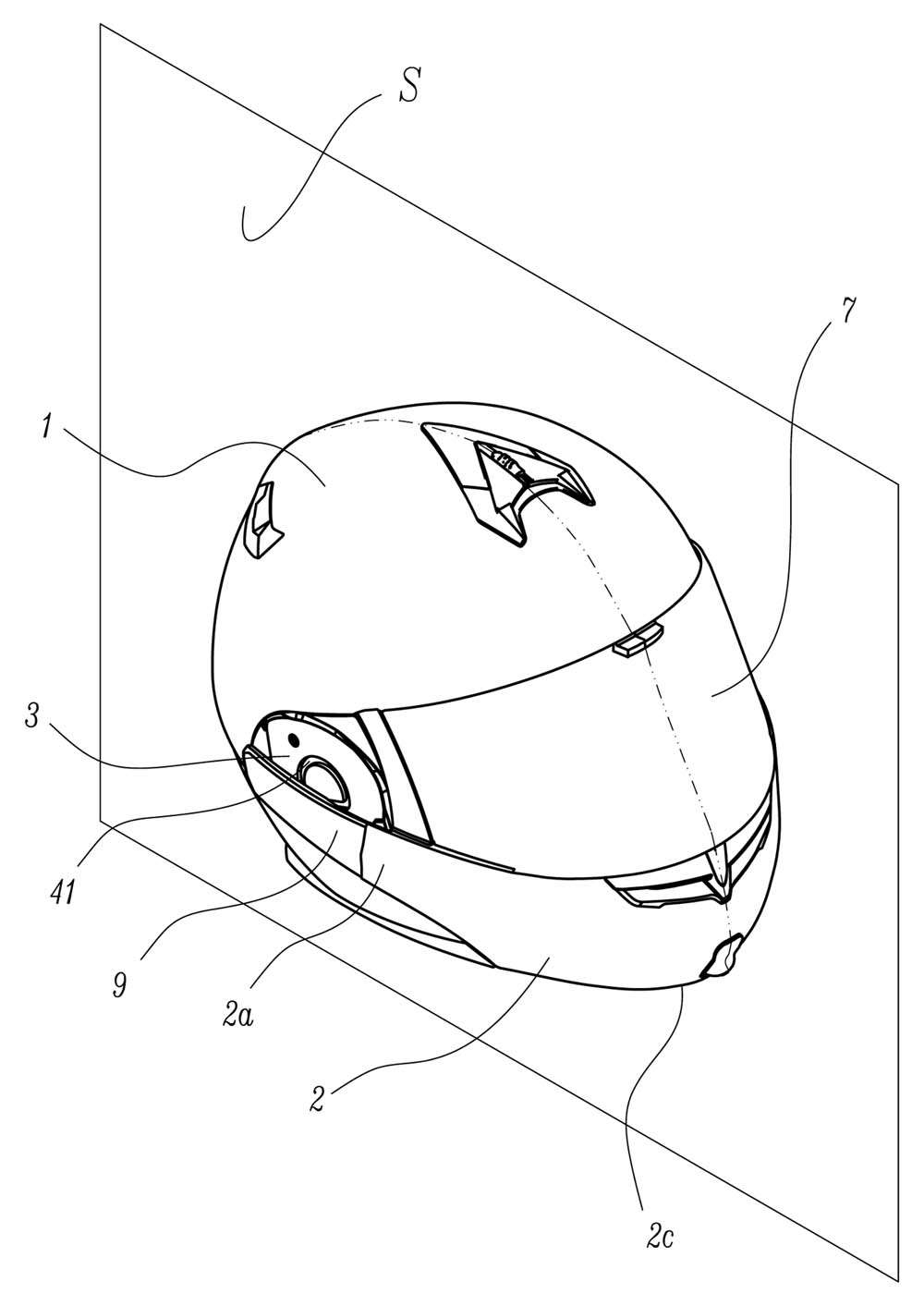

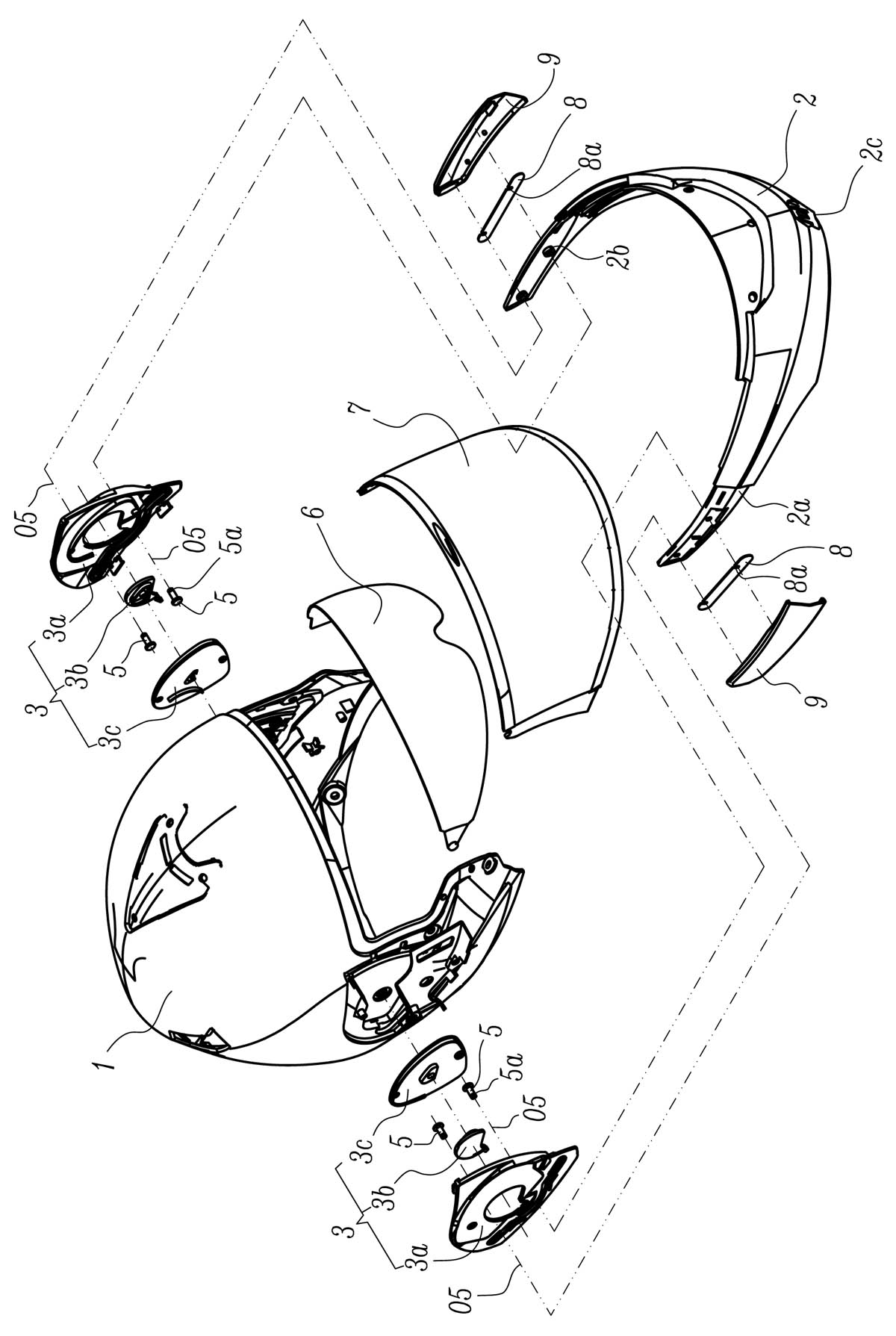

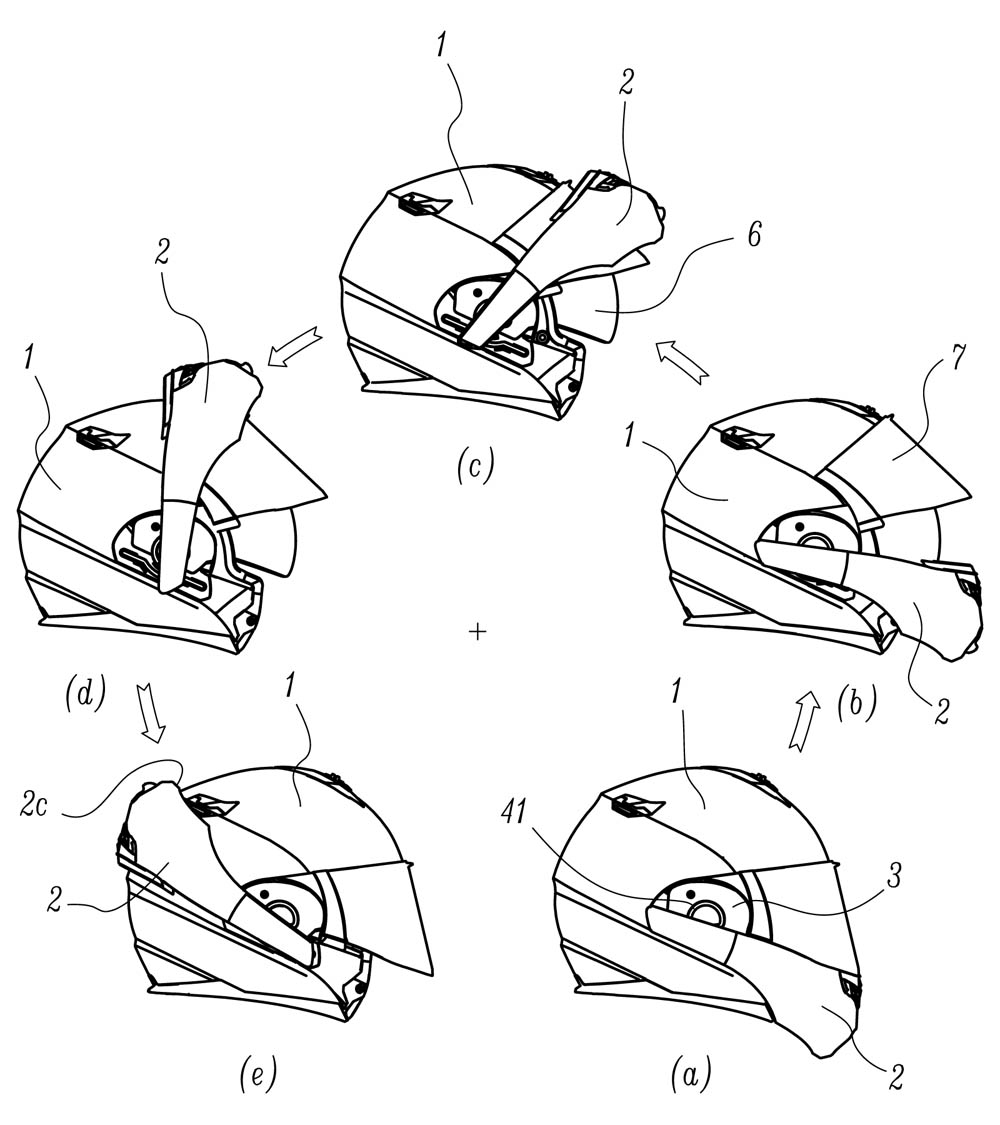

[0063] The present invention will be further described below with specific embodiment, see figure 1 —31:

[0064] A helmet with a variable jaw guard structure, comprising: a helmet shell main body 1, a jaw guard 2 and two templates 3, the jaw guard 2 has two fork handles 2a, and the two templates 3 are separately placed on the helmet shell main body 1 Two sides; the biggest feature of the present invention is that two groove-shaped tracks (41, 42) are opened on each template 3, and each track (41, 42) in the tracks (41, 42) can be formed by a complete The groove track of a section (that is, the groove rail of this section is generated according to the same law method), or it can be formed by the butt joint of several sections of groove rail (that is, the groove rail sections generated by different rules are connected to form a combined track), so as to Figure 10 For example, the track 41 is a complete circular groove, and the track 42 is connected by a total of five grooves:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com