Flame retardant polymer blends

A technology of flame-retardant polymers and blends, which is applied in the field of polyimide and can solve the problems of opacity of PEI-PC blends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

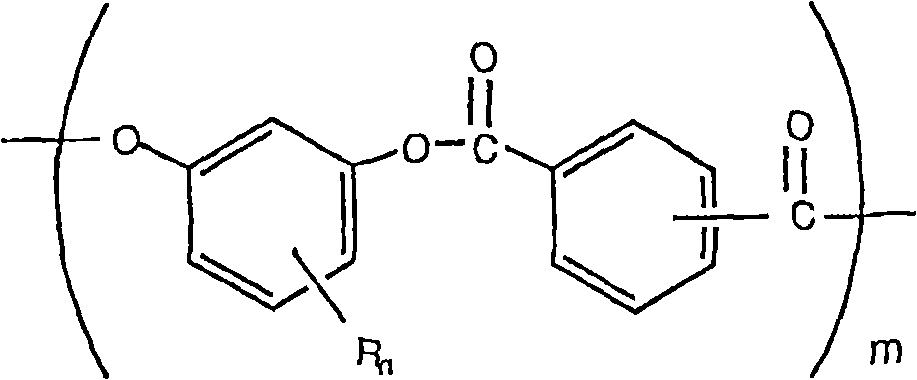

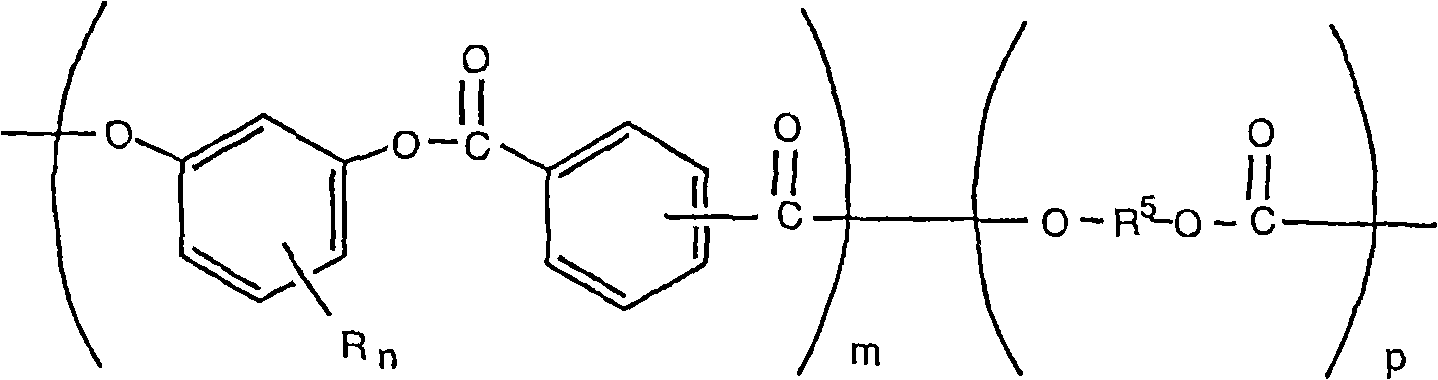

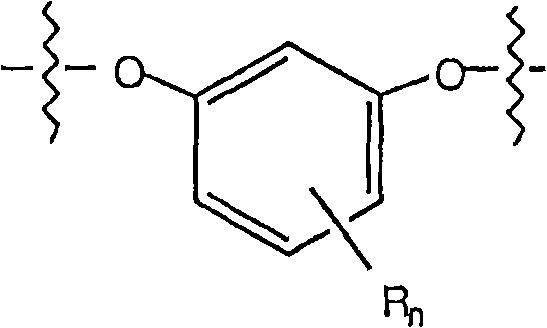

[0004] Combinations of silicone copolymers, such as silicone polyimide or silicone polycarbonate, and high glass transition temperature (Tg) polyimide (PI), polyetherimide (PEI) and poly The combination of an etherimide sulfone (PEIS) resin, and a resorcinol-derived aryl polyester has surprisingly low exotherm values and improved solvent resistance. The resorcinol-derived aryl polyesters may also be copolymers containing non-resorcinol linkers, such as resorcinol-bisphenol A copolyestercarbonate. For better results, the resorcinol ester content (REC) should be greater than about 50 mol% of the resorcinol-derived polymer linker. A higher REC may be preferred. In some cases, a REC of greater than 75 mol% of the resorcinol-derived linker, or as high as 90 or 100 mol%, may be desirable.

[0005] The amount of resorcinol ester-containing polymer used in the flame retardant blend can vary widely, and any effective amount can be used to reduce exotherm, increase time to peak exot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com