Preparing method of hexagonal boron nitride/polystyrene composite

A hexagonal boron nitride and polystyrene technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of complex processing technology, low thermal conductivity, and difficult to process and shape, and achieve strong controllability and high Effects of mechanical properties and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

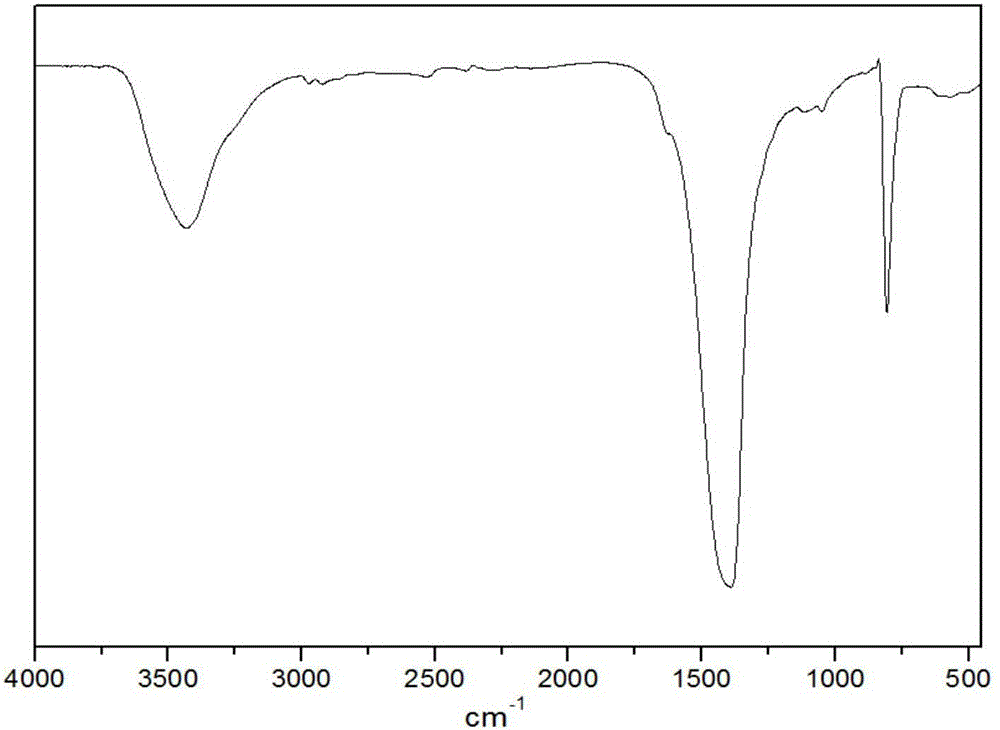

[0028] 1) Hexagonal boron nitride pretreatment: KH-570 (the amount of coupling agent added is 2% of the total mass of hexagonal boron nitride and styrene) and 200ml deionized water, magnetically stirred for about 20min, and hexagonal boron nitride Add in the solution and continue magnetic stirring for 40min, then continue stirring for 30min in a 70°C water bath, filter, and obtain boron nitride powder ( figure 1 ), figure 1 The peak positions shown are consistent with those reported for boron nitride in the literature. Located at 783cm -1 and 1383cm -1 The absorption band is the characteristic absorption peak of hexagonal boron nitride, of which 783cm -1 The absorption peak corresponding to the out-of-plane bending vibration of the B-N-B bond, while 1383cm -1 The in-plane stretching vibration absorption peak corresponding to the B-N bond. Dry at 110°C for 12 hours, and grind the dried boron nitride powder with a mortar for use.

[0029] 2) Preparation of h-BN@PS masterba...

Embodiment 2

[0033] The preparation method is the same as that in Example 1, except that, according to the mass ratio, hexagonal boron nitride:styrene=1:16.7, and the mass ratio of hexagonal boron nitride and polystyrene polymer is 1:61.

[0034] The mechanical properties of the obtained hexagonal boron nitride / polystyrene polymer composite were tested, and the test results are shown in Table 1.

Embodiment 3

[0036] The preparation method is the same as in Example 1, except that, according to the mass ratio, hexagonal boron nitride: styrene = 1:11.1, and the mass ratio of hexagonal boron nitride and polystyrene polymer is 1:40.7.

[0037] The mechanical properties of the obtained hexagonal boron nitride / polystyrene polymer composite were tested, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com