Recyclable nanocellulose reinforced polypropylene material and preparation method and application thereof

A polypropylene material and nano-cellulose technology, applied in the field of materials, can solve the problems of unrecyclable materials, insufficient rigidity, and high weight, and achieve the effects of recyclable, stable overall structure, and low processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

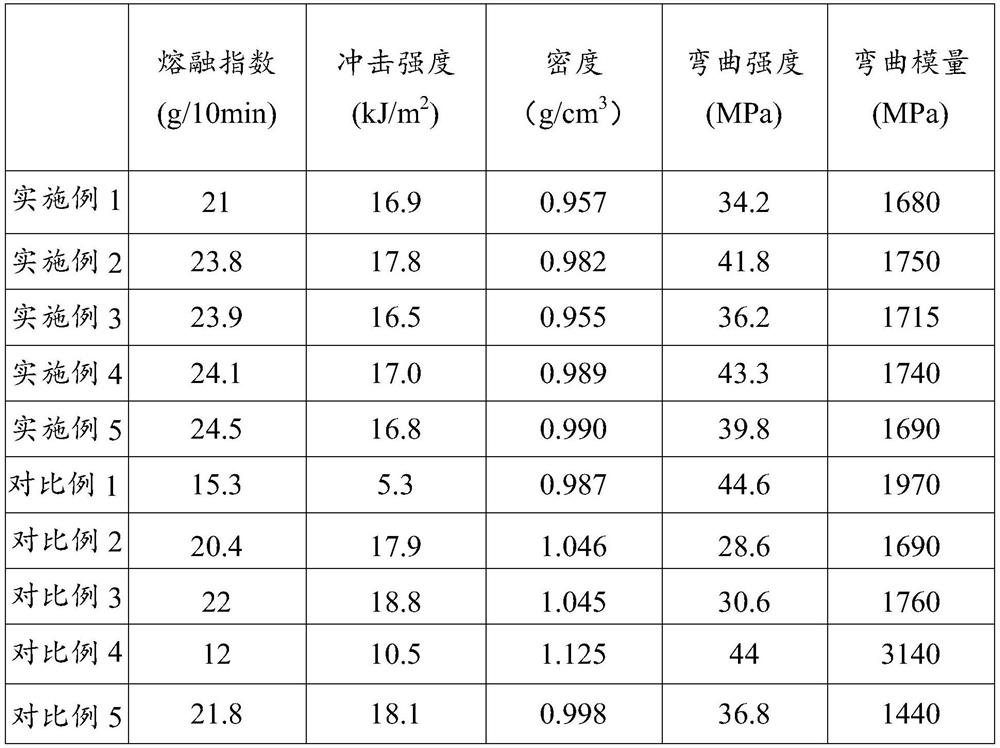

Examples

preparation example Construction

[0029] Another aspect of the embodiments of the present invention provides a method for preparing a recyclable nanocellulose-reinforced polypropylene material, comprising the following steps:

[0030] 49.5-73.5 parts of copolymerized polypropylene, 15-35 parts of nano-plant cellulose, 10-15 parts of ethylene-octene copolymer elastomer, 1.5-3 parts of polypropylene maleic anhydride graft and 0.5-1.5 parts of processing aid After the parts are mixed, melt extrusion and pelletization are carried out to obtain a recyclable nanocellulose reinforced polypropylene material.

[0031] The preparation method provided by the invention has simple process and is suitable for industrial application.

[0032] In the present invention, the mixing is preferably dry mixing, the mixing speed of the dry mixing is preferably 400-600 rpm, and the dry mixing time is preferably 5-10 minutes. In the embodiment of the present invention, the mixing is preferably performed in a high-speed mixer, and the...

Embodiment 1

[0044] Example 1, the nano-cellulose reinforced polypropylene material includes the following raw materials: 49.5 kg of polypropylene copolymer, 15 kg of nano-plant cellulose, 10 kg of ethylene-octene copolymer elastomer, polypropylene maleic anhydride graft 1.5kg, antioxidant 1010 0.2kg, antioxidant 168 0.1kg and nucleating agent 0.2kg.

[0045] Stir the weighed raw materials in a vertical stirring high-speed mixer at a speed of 600rpm for 10 minutes, and then transport them to a twin-screw extruder for melt extrusion, granulation and drying to obtain green low-carbon recyclable injection molding Grade nano plant cellulose reinforced polypropylene; the temperature of each temperature zone of the extruder is: 100°C in the first zone, 110°C in the second zone, 130°C in the third zone, 140°C in the fourth zone, 160°C in the fifth zone, 165°C in the sixth zone, 170°C in the seventh zone, 170°C in the eighth zone, 175°C in the ninth zone, 170°C in the tenth zone, and 180°C in the ...

Embodiment 2

[0046] Embodiment 2 is the best embodiment of the present invention, the nanocellulose reinforced polypropylene material includes the following raw materials: 51.5kg of polypropylene copolymer, 30kg of nano plant cellulose, 15kg of ethylene-propylene copolymer elastomer, 3kg of polypropylene maleic anhydride graft, 0.2kg of antioxidant 1010, 0.1kg of antioxidant 168, and 0.2kg of nucleating agent.

[0047] According to the method of Example 1, a green low-carbon recyclable injection molding grade nano-plant cellulose reinforced polypropylene automotive interior material was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com