Injection molding grade flame retardant PVC/ABS alloy material and preparation method thereof

An alloy material, injection molding technology, applied in the polymer field, can solve the problems of affecting the appearance and performance of the product, poor thermal stability, large smoke volume, etc., to improve processing stability, good thermal stability, and not easy to burn yellow burnt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

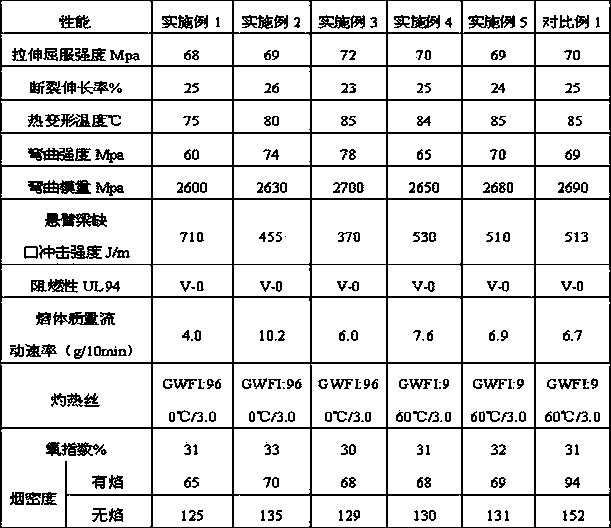

Examples

preparation example Construction

[0056] Another object of the present invention is to propose a method for preparing an injection-molded grade flame-retardant PVC / ABS alloy material with advantages such as good processing fluidity, good thermal stability, good flame retardancy and low smoke density. The steps of the method are as follows:

[0057] (1) Preparation of smoke suppressant: first prepare magnesium hydroxide coated with zinc hypophosphite by reacting zinc sulfate and sodium hypophosphite, and then prepare magnesium hydroxide coated with zinc hypophosphite in a weight ratio of (15~20):1 Magnesium is mixed with molybdenum oxide to obtain smoke suppressant;

[0058] (2) First weigh each component according to the formula amount, then put PVC resin, heat stabilizer and other additives into the high-speed mixer, stir at low speed for 30s, add plasticizer, and turn to high-speed mixing; when the temperature of the material rises When the temperature reaches 85°C, add processing aids; when the material tem...

Embodiment 1

[0062] This embodiment prepares the raw material composition of injection molding grade flame-retardant PVC / ABS alloy material as follows table 1:

[0063] components raw material name parts by weight PVC resin PVC resin 33 ABS resin ABS resin 36 Heat stabilizers Organotin Heat Stabilizer 3 Processing aids Methyl methacrylate-methyl acrylate core-shell copolymer 5 impact modifier Chlorinated polyethylene with a chlorine content of 30~45% 4 heat resistance modifier N-Substituted Maleimide Copolymer 2 plasticizer Diisononyl phthalate 2 flame retardant Long-chain chlorinated paraffin with a chlorine content of about 70% 5 smoke suppressant smoke suppressant 5 Other additives Phenolic Antioxidants 5

[0064] Table 1

[0065] The steps of a preparation method of an injection molding grade flame-retardant PVC / ABS alloy material are as follows:

[0066] (1) Preparation of smoke suppre...

Embodiment 2

[0070] This embodiment prepares the raw material composition of injection molding grade flame-retardant PVC / ABS alloy material as follows table 2:

[0071] components raw material name parts by weight PVC resin PVC resin 33 ABS resin ABS resin 38 Heat stabilizers epoxy compound 2 Processing aids Acrylic copolymer with core-shell structure 3 impact modifier Ethylene-propylene-diene terpolymer 4 heat resistance modifier α-Methylstyrene copolymer or blend 4 plasticizer Phosphite Antioxidants 3 flame retardant Decabromodiphenylethane + antimony trioxide 6 smoke suppressant smoke suppressant 4 Other additives Dioctyl terephthalate 3

[0072] Table 2

[0073] Compared with the preparation method of Example 1, the preparation method of this example differs in that the mass ratio of magnesium hydroxide coated with zinc hypophosphite to molybdenum oxide is 16:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Smoke density level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com