Heat-conducting nylon composite special for injection molding-grade LED lamps and preparation method thereof

A nylon composite material, LED lamp technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of weak thermal conductivity, large amount of thermally conductive fillers, complicated processing technology, etc., to achieve improved thermal conductivity and excellent thermal conductivity. Conductive ability, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

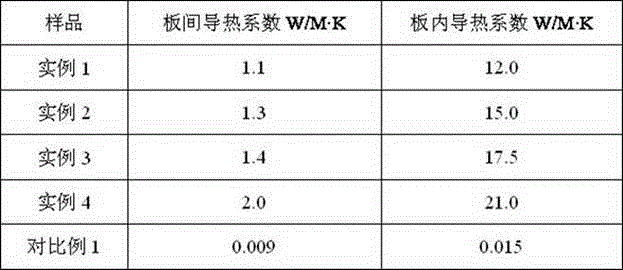

Examples

Embodiment 1

[0024] The composition ratio of the preparation of a thermally conductive nylon composite material for injection molding grade LED lamps:

[0025] Attapulgite / alumina 20.0 parts, 5.0 parts of Japanese Kao EBS as dispersant, 1.0 part of fumed silica as dispersant, 1.0 part of nano-silica with an average particle size of 600nm as other additives, 1.0 part of nano-silica with an average particle size of 600nm, and PA6 Huajian nylon 73.0 parts.

[0026] First, vacuum dry PA6 at 120°C for 4 hours, then physically mix the raw materials according to the above ratio, and then extrude and granulate with twin-screw, the processing temperature is 255°C, and the rotation speed is 250r / min.

Embodiment 2

[0028] The composition ratio of the preparation of a thermally conductive nylon composite material for injection molding grade LED lamps:

[0029] Attapulgite / alumina 25.0 parts, 5.0 parts of Japanese Kao EBS as dispersant, 1.0 part of fumed silica as auxiliary dispersant, 1.0 part of nano-silica with an average particle size of 600nm as other additives, and 1.0 part of nano-silica with an average particle size of 600nm, PA6 Huajian nylon 68.0 parts.

[0030] First, vacuum dry PA6 at 120°C for 4 hours, then physically mix the raw materials according to the above ratio, and then extrude and granulate with twin-screw, the processing temperature is 255°C, and the rotation speed is 250r / min.

Embodiment 3

[0032] The composition ratio of the preparation of a thermally conductive nylon composite material for injection molding grade LED lamps:

[0033] Attapulgite / alumina 30.0 parts, 5.0 parts of Japanese Kao EBS as dispersant, 1.0 part of fumed silica as auxiliary dispersant, 1.0 part of nano-silica with an average particle size of 600nm as other additives, 1.0 part of nano-silica with an average particle size of 600nm, and PA6 Huajian nylon 63.0 parts.

[0034] First, vacuum dry PA6 at 120°C for 4 hours, then physically mix the raw materials according to the above ratio, and then extrude and granulate with twin-screw, the processing temperature is 255°C, and the rotation speed is 250r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com