Permanently antistatic PC/ASA material

A permanent antistatic agent and antistatic technology, which is applied in the field of permanent antistatic PC/ASA materials, can solve the problems of loss of antistatic effect, short antistatic time, and resistance to washing, and achieve cost reduction, high gloss, and Good light resistance

Inactive Publication Date: 2010-08-18

SHANGHAI JINCHANG ENG PLASTICS CO LTD

View PDF3 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] At present, the antistatic materials commonly used in the market are mainly to add some low molecular weight antistatic agents to the materials, which mainly rely on the precipitation of low molecular weight substances to form a hydrophilic layer on the surface of the material to produce antistatic effects, but its main disadvantage is that the antistatic time is short. Not resistant to washing, will lose antistatic effect in a short time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0022] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

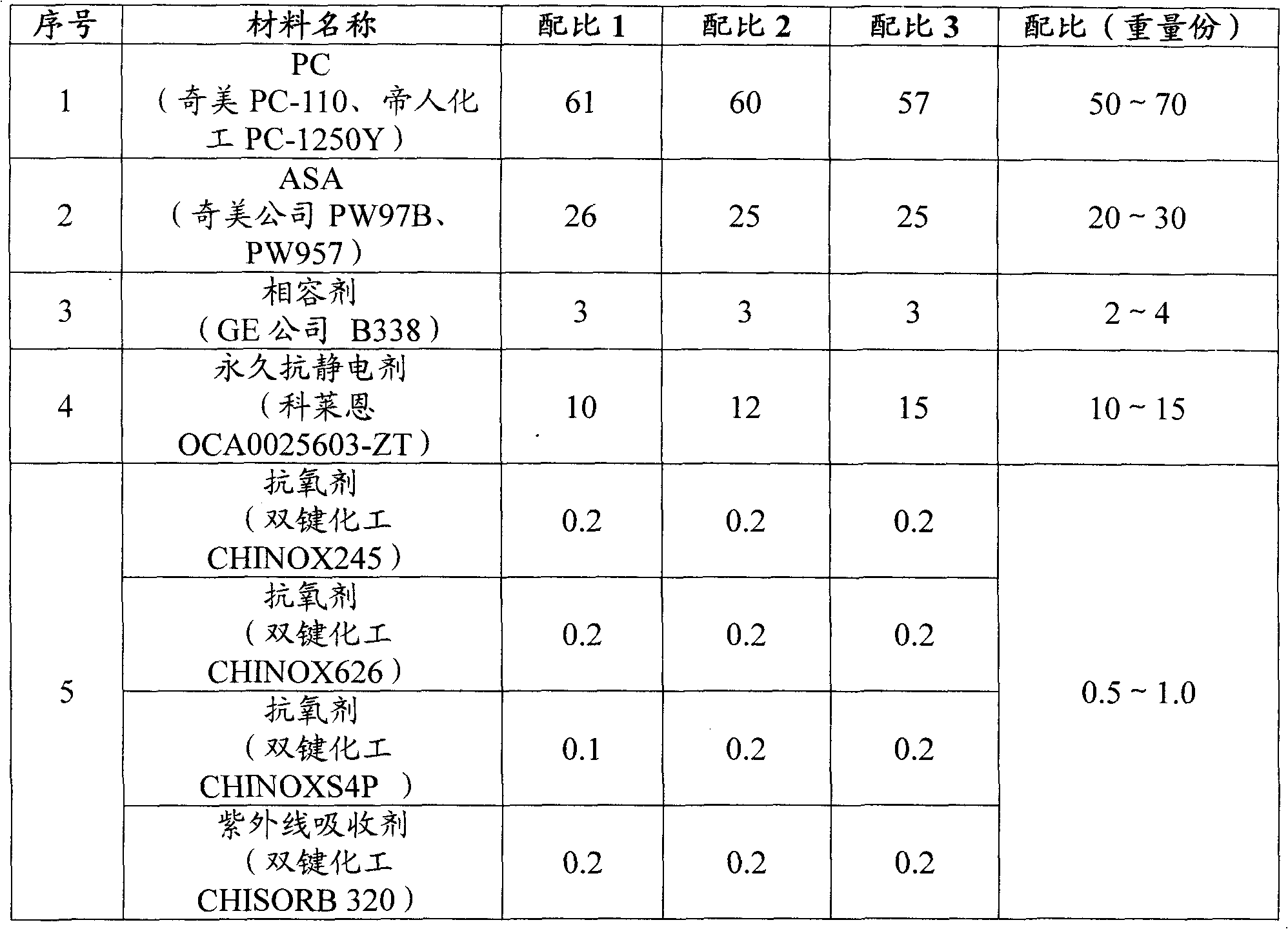

[0023] According to the following table, weigh PC, ASA, compatibilizer and additives in proportion, and add a certain amount of permanent antistatic agent:

[0024]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a permanently antistatic PC / ASA material, which comprises the following components by weight part: 50-70 parts of PC, 20-30 parts of ASA, 10-15 parts of permanent antistatic agent, 2-4 parts of compatibilizer and 0.5-1.0 part of additive, 0.4-0.7 part of antioxidant and 0.1-0.3 part of ultraviolet absorbent, wherein the additive comprises the antioxidant and the ultraviolet absorbent, and the permanent antistatic agent is synthesized based on polyamide and hindered amine polyether; the compatibilizer is of a PC / ASA special alloy modifier, and the PC comprises one or more of high-melting injection molding grade PC; and the ASA comprises one or more of high-gloss and high-mobility ASA. The invention has high gloss, good heat and light resistant performances, permanent anti-static property and wash resistance, thereby prolonging service life, reducing use cost, and being suitable for industrial scale production and large-scale popularization and application.

Description

technical field [0001] The invention relates to the technical field of polymer materials, in particular to the technical field of PC / ASA alloy materials, in particular to a permanent antistatic PC / ASA material. Background technique [0002] PC is polycarbonate, a new type of thermoplastic, with a transparency of 90%, rigidity and toughness, high impact strength, high dimensional stability, wide range of operating temperature, and good electrical insulation properties And heat resistance and non-toxicity, can be molded by injection and extrusion. [0003] ASA is a terpolymer composed of acrylonitrile-styrene-acrylate, which is an engineering plastic developed for the disadvantage of ABS's poor weather resistance. It integrates the impact resistance and weather resistance of acrylate, the chemical resistance and high hardness of acrylonitrile, and the excellent processability of styrene. It has good mechanical properties and excellent weather resistance, and is especially sui...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L69/00C08L51/00

Inventor 谢荣海陈静周容孙佳

Owner SHANGHAI JINCHANG ENG PLASTICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com