Injection molding grade environment-friendly anti-flaming ultra-high molecular weight polyethylene and preparation method thereof

A technology of ultra-high polymer and polyethylene, applied in the field of polymer materials, can solve the problems of high price, inability to produce high-performance additive products, and high technical processing requirements, and achieve good self-lubricating properties, high impact mechanical properties, and use The effect of a wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

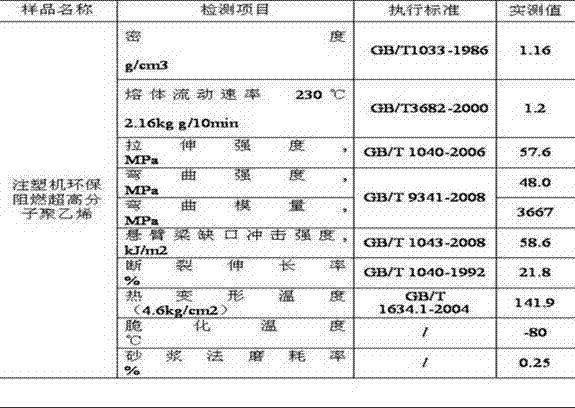

Image

Examples

Embodiment 1

[0025] UHMWPE powder in parts by weight: 45 parts, flame retardant; 5 parts, liquid crystal polymer; 8 parts, heat stabilizer; 2 parts, compatibilizer; Mix for 20 minutes, extrude and granulate at 220°C through a twin-screw extrusion granulator to obtain injection-grade environmentally friendly flame-retardant ultra-high molecular weight polyethylene.

Embodiment 2

[0027] Ultra-high molecular weight polyethylene with a molecular weight of more than 3.5 million in parts by weight: 80 parts, silicon nitrogen compound halogen-free environmental protection flame retardant; 20 parts, low melting point liquid crystal polymer; 20 parts, calcium zinc liquid compound heat stabilizer ; 5 parts, the compatibilizer of maleic anhydride grafted polyethylene; 10 parts were mixed at 90°C for 15 minutes by a high-speed kneader, extruded and granulated by a twin-screw extrusion granulator within the range of 190°C to obtain injection molding Grade environmentally friendly flame-retardant ultra-high molecular weight polyethylene.

Embodiment 3

[0029] Ultrahigh molecular weight polyethylene with a molecular weight of more than 3.5 million in parts by weight: 60 parts, silicon nitrogen composite halogen-free environmental protection flame retardant; 15 parts, low melting point liquid crystal polymer; 15 parts, zinc liquid composite thermal stabilizer; 4 parts, a compatibilizer for maleic anhydride grafted polyethylene; 8 parts were mixed at 100°C by a high-speed kneader for 18 minutes, extruded and granulated by a twin-screw extruder at 200°C to obtain injection molding grade Environmentally friendly flame-retardant ultra-high molecular polyethylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com