Injection-molding-grade nylon 6 composite material and application thereof

A composite material, injection molding technology, applied in the field of nylon materials, can solve problems such as inability to demold, and achieve the effects of excellent dimensional stability, rapid demoulding, and excellent cold resistance and heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

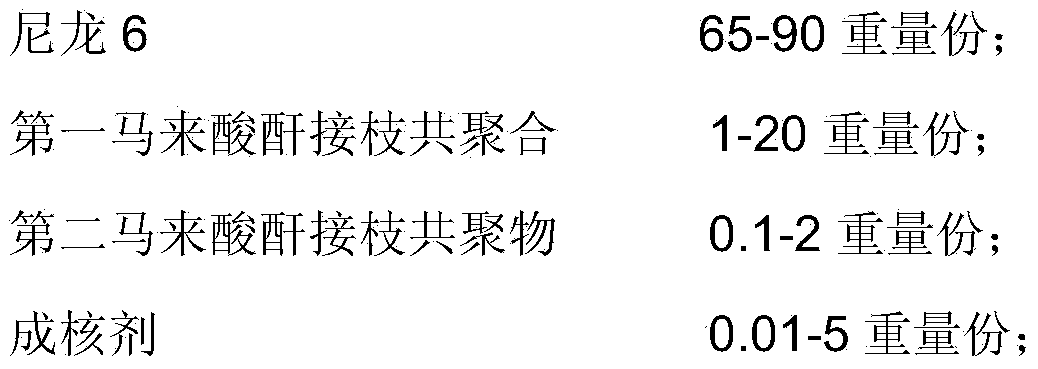

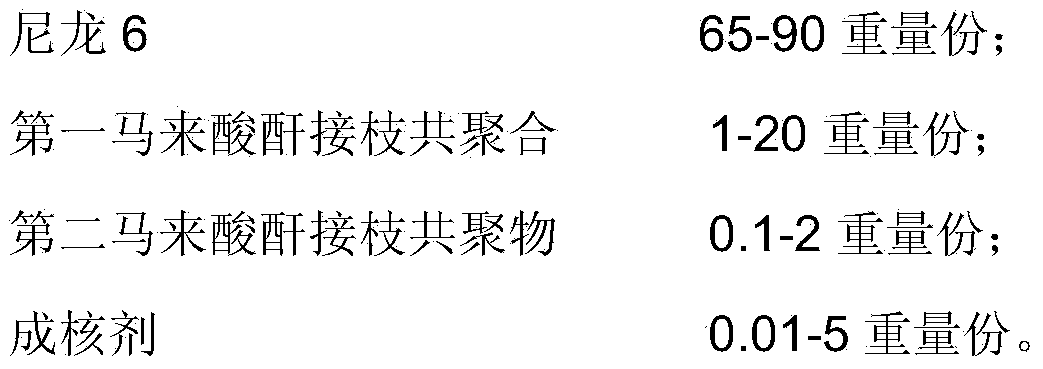

[0055]

[0056] Wherein, the POE-g-MAH graft copolymer is first made into a 30wt% masterbatch with some nylon 6, and then mixed.

[0057] After the above components are mixed, they are extruded through a twin-screw extruder, injected into the inner wall of the ring-shaped zinc-based alloy, and molded, wherein the holding time is 2-3s. After demolding, there is no phenomenon of locking the mold. It only takes 16.5s to complete the injection molded parts.

[0058] After cooling, the resin layer and the zinc-based alloy did not detach. Heating to 90°C (holding for 2h), then cooling to 30°C (holding for 2h), and performing 10 cycles showed no trace of linear separation between the resin layer and the zinc-based alloy.

Embodiment 2

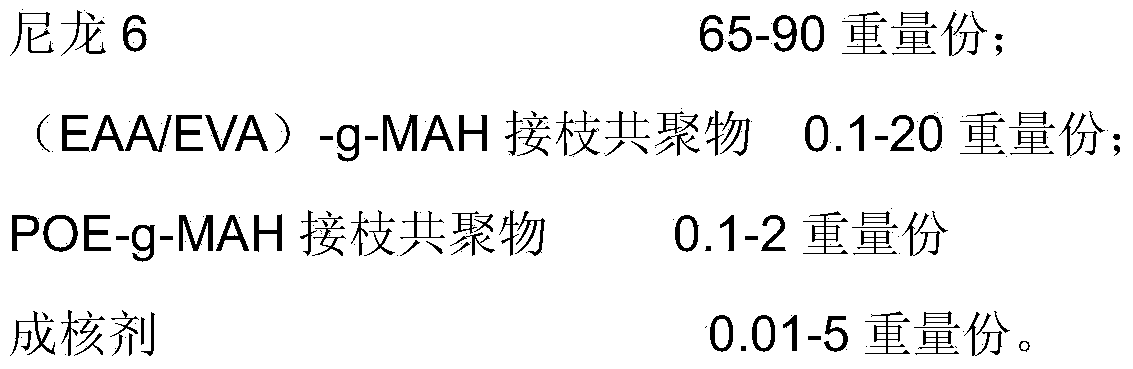

[0060]

[0061]

[0062] Wherein, the POE-g-MAH graft copolymer is first made into a 30wt% masterbatch with some nylon 6, and then mixed.

[0063] After the above components are mixed, they are extruded through a twin-screw extruder, injected into the inner wall of the ring-shaped zinc-based alloy, and molded, wherein the holding time is 2-3s. After demolding, there is no phenomenon of locking the mold.

[0064] After cooling, the resin layer and the zinc-based alloy did not detach. Heating to 90°C (holding for 2h), then cooling to 30°C (holding for 2h), and performing 10 cycles showed no trace of linear separation between the resin layer and the zinc-based alloy.

Embodiment 3

[0066]

[0067] Wherein, the POE-g-MAH graft copolymer is first made into a 30wt% masterbatch with some nylon 6, and then mixed.

[0068] After cooling, the resin layer and the zinc-based alloy did not detach. Heating to 90°C (holding for 2h), then cooling to 30°C (holding for 2h), and performing 10 cycles showed no trace of linear separation between the resin layer and the zinc-based alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com