Transparent flame-retardant high-temperature nylon and preparation method thereof

A high-temperature, nylon technology, applied in the field of transparent flame-retardant high-temperature nylon and its preparation, can solve the problems of reducing the processing fluidity and surface quality of products, the influence of high-temperature nylon optical and mechanical properties, etc., to solve the problems of poor optical and mechanical properties, adding Small amount, guaranteeing the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] This embodiment also provides a method for preparing the above-mentioned transparent flame-retardant high-temperature nylon, which includes:

[0044] Step S1: Mix the dried high-temperature nylon, bridged chain DOPO derivatives and nano silicon dioxide in parts by weight to obtain a mixed base material.

[0045] Further, the drying temperature of high-temperature nylon, bridged chain DOPO derivatives and nano-silica is 90-110°C, or 95-105°C, or 98-102°C; the drying time is 10-15 hours, or 11-10 hours. 14h, or 12-13h.

[0046] Further, it also includes putting high-temperature nylon, bridged chain DOPO derivatives and nano silicon dioxide into a high-speed mixing mixer, and mixing for 5-10 minutes to form a mixed base material;

[0047] More preferably, it also includes: mixing bridge chain DOPO derivatives and nano-silica in a high-speed mixer for 5 to 20 minutes to obtain a uniform flame retardant composition; then mixing high-temperature nylon and flame retardant com...

Embodiment 1

[0053] This embodiment provides a transparent flame-retardant high-temperature nylon, which includes by weight parts:

[0054] 90 parts of semi-aromatic high-temperature nylon resin, 9.8 parts of bridged chain DOPO derivatives (with a particle size of 5-6 μm), and 0.2 parts of nano-silica (with a particle size of 40-60 nm).

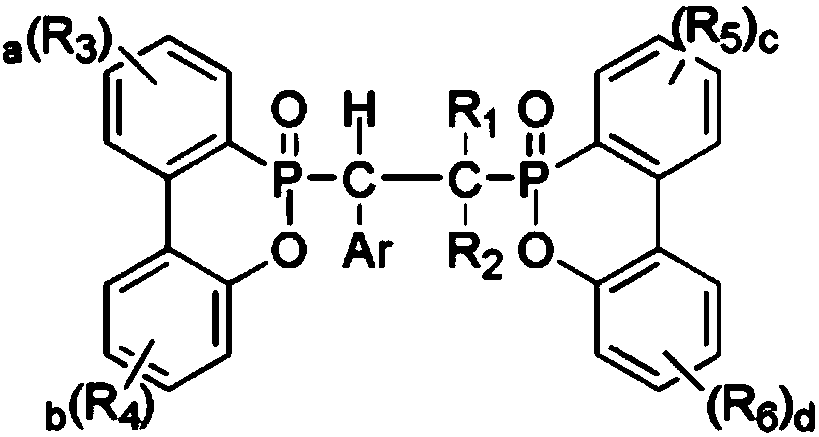

[0055] The molecular formula of the bridged chain DOPO derivative is formula I:

[0056]

[0057] The preparation method of the transparent flame-retardant high-temperature nylon comprises:

[0058] a. Mix the bridge chain DOPO derivatives and nano silicon dioxide in a high-speed mixer for 10 minutes to obtain a uniform flame retardant composition;

[0059] b. Dry the high-temperature nylon and flame retardant composition at 100° C. for 12 hours; then put the dried high-temperature nylon and flame retardant composition into a high-speed mixer and mix evenly to obtain a mixed base material;

[0060] c. Add the mixed base material to a twin-screw extru...

Embodiment 2

[0063] This embodiment provides a transparent flame-retardant high-temperature nylon, which includes by weight parts:

[0064] 85 parts of semi-aromatic high-temperature nylon resin, 14.8 parts of bridged chain DOPO derivative (compound of formula I, particle size 5-6 μm), 0.2 part of nano silicon dioxide (particle size 40-60 nm).

[0065] Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com