Wear-resistant and scraping-resistant injection-molding-grade PC/ABS alloy material and preparing method thereof

An alloy material, injection molding grade technology, applied in the field of injection molding PC/ABS alloy material and its preparation, can solve the problems of reducing the compatibility of PC and ABS, reducing the processing performance of PC/ABS, and limiting the application of PC/ABS, etc. Achieve the effects of improved compatibility, processability, high gloss, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

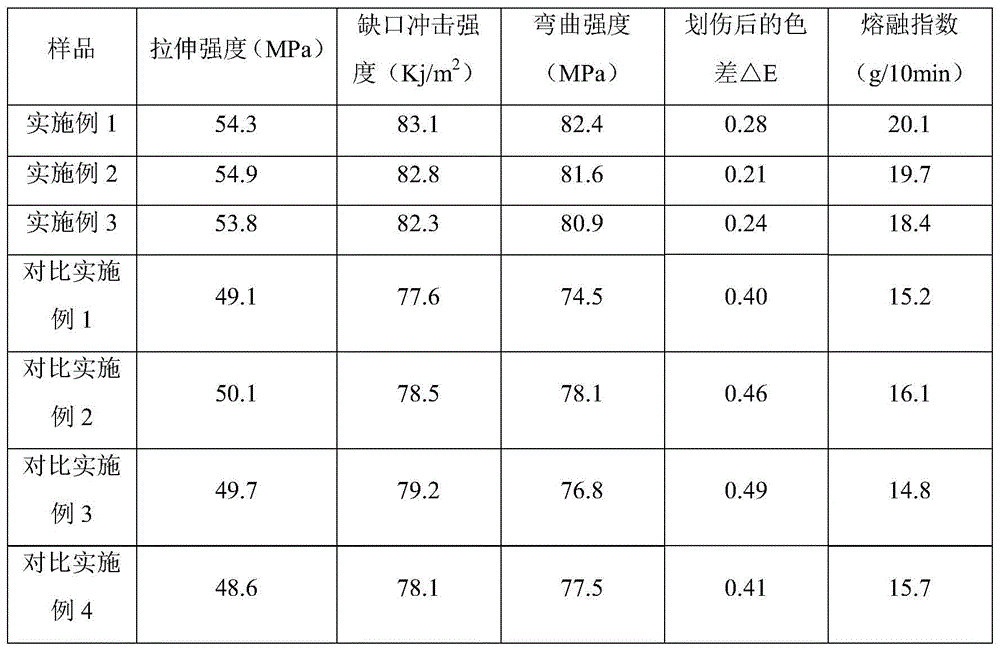

Examples

Embodiment 1

[0022] Embodiment 1, a kind of wear-resistant and scratch-resistant injection molding grade PC / ABS alloy material is made up of following composition by weight ratio, and PC is 45%, and ABS is 42%, compound type compatibilizer (polyolefin elastomer POE The compounding ratio with modified polyolefin is 1:1, the maleic anhydride graft grafting rate is 3%) is 5%, compound toughening agent is 3%, lubricant (PBT, polymerization degree is 600, viscosity 0.7) is 3%, antioxidant is 1%, anti-ultraviolet agent is 1%; And prepare according to the following steps:

[0023] 1) Put PC, ABS, compound compatibilizer, compound toughening agent, lubricant PBT resin, antioxidant, anti-ultraviolet agent into the high-speed mixer in proportion to carry out mixing treatment, and mix and stir for 5 minute;

[0024] 2) Then put the mixture into a twin-screw extruder, extrude through the extruder, granulate and air-dry to obtain a scratch-resistant injection molding grade PC / ABS alloy material; the s...

Embodiment 2

[0029] Embodiment 2, a kind of wear-resistant and scratch-resistant injection molding grade PC / ABS alloy material is made up of following composition by weight ratio, and PC is 75%, and ABS is 15%, compound type compatibilizer (polyolefin elastomer POE The compounding ratio with modified polyolefin is 1:3, the maleic anhydride graft graft rate is 5%) is 4%, compound toughening agent is 2%, lubricant (PBT, degree of polymerization is 800, Viscosity is 0.9) is 3%, antioxidant is 0.5%, and antiultraviolet agent is 0.5%, and prepares as follows;

[0030] 1) Put PC, ABS, compound compatibilizer, compound toughening agent, lubricant PBT resin, antioxidant, anti-ultraviolet agent into the high-speed mixer in proportion to carry out material mixing treatment, mix and stir for 10 minute;

[0031] 2) Then put the mixture into a twin-screw extruder, extrude through the extruder, granulate and air-dry to obtain a scratch-resistant injection molding grade PC / ABS alloy material and its pre...

Embodiment 3

[0036] Embodiment 3, a kind of wear-resistant and scratch-resistant injection molding grade PC / ABS alloy material is made up of following composition by weight ratio, and PC is 35%, and ABS is 60%, compound type compatibilizer (polyolefin elastomer POE The compounding ratio with modified polyolefin is 1:2, the maleic anhydride graft graft rate is 4%) is 2%, compound toughening agent is 1%, lubricant (PBT, degree of polymerization is 500, Viscosity is 0.9) be 1%, antioxidant is 0.5%, antiultraviolet agent is 0.5%, and prepares as follows:

[0037] 1) Put PC, ABS, compound compatibilizer, compound toughening agent, lubricant PBT resin, antioxidant, and anti-ultraviolet agent into the high-speed mixer for mixing treatment, and mix and stir for 5 minutes;

[0038] 2) Then put the mixture into a twin-screw extruder, extrude through the extruder, granulate and air-dry to obtain a scratch-resistant injection molding grade PC / ABS alloy material and its preparation method; the screw sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com