Injection molding grade degradable polylactic acid wood plastic micro-foaming composite material and preparation method thereof

A technology of polylactic acid wood and composite materials, applied in the field of wood-plastic materials, can solve the problems of low melt strength of polylactic acid, poor compatibility of wood powder and polylactic acid, affecting the performance of polylactic acid, etc., and achieve flexible product design and uniform distribution. , the effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

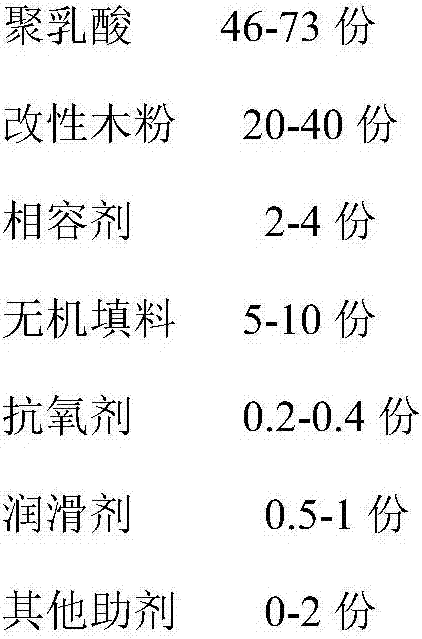

Method used

Image

Examples

preparation example Construction

[0035] Concrete preparation method comprises the following steps:

[0036] (1) First bake the poplar wood powder at 120-150°C for 5-8 hours to ensure that the water content of the wood powder is controlled below 0.8%. Weigh 69 parts of the dried wood powder, 30 parts of toluene diisocyanate and 1 part of the catalyst into the Add an appropriate amount of zirconium balls into a PTFE ball mill tank, and mill in a planetary ball mill for 10 minutes, wherein the revolution is 60-100r / min, and the rotation is 100-200r / min. After the reaction, the graft is extracted with acetone for 48 hours to constant weight , to obtain modified poplar wood powder.

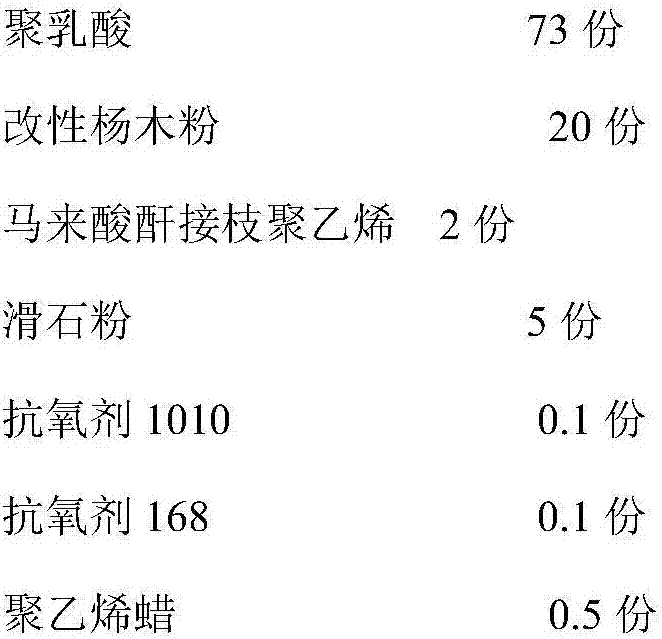

[0037] (2) 73 parts of polylactic acid, 2 parts of maleic anhydride grafted polyethylene, 5 parts of talcum powder, 0.1 part of antioxidant 1010, 0.1 part of oxygen agent 168, and 0.5 part of polyethylene wax were mixed in a high-speed mixer for 10 minutes, and put into In the main feed of the co-rotating twin-screw extruder, weigh 2...

Embodiment 2

[0040] The injection-grade polypropylene wood-plastic micro-foaming composite material in this embodiment is composed of the following raw materials according to weight percentage:

[0041] Polylactic acid wood plastic composite material 97%

[0042] Sodium bicarbonate is a chemical blowing agent wrapped in LDPE carrier 3%

[0043] The polylactic acid wood-plastic composite material described therein consists of the following raw materials by weight:

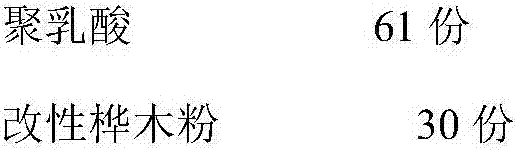

[0044]

[0045]

[0046] Concrete preparation method comprises the following steps:

[0047] (1) First bake the birch powder at 120-150°C for 5-8 hours to ensure that the water content of the wood powder is controlled below 0.8%, weigh 49 parts of the dried wood powder, 49 parts of diphenylmethane diisocyanate, and 2 parts of the catalyst. Put it into a polytetrafluoroethylene ball mill tank, add an appropriate amount of zirconium balls, and mill it in a planetary ball mill for 10 minutes, wherein the revolution is 60-100r...

Embodiment 3

[0051] The injection-grade polypropylene wood-plastic micro-foaming composite material in this embodiment is composed of the following raw materials according to weight percentage:

[0052] Polylactic acid wood plastic composite material 97%

[0053] Sodium bicarbonate is a chemical blowing agent wrapped in LDPE carrier 3%

[0054] The polylactic acid wood-plastic composite material described therein consists of the following raw materials by weight:

[0055]

[0056]

[0057] Concrete preparation method comprises the following steps:

[0058] (1) First bake poplar wood powder at 120-150°C for 5-8 hours to ensure that the water content of the wood powder is controlled below 0.8%, weigh 40 parts of dried wood powder, 57 parts of diphenylmethane diisocyanate, and 3 parts of catalyst Put it into a polytetrafluoroethylene ball mill jar, add an appropriate amount of zirconium balls, and mill it in a planetary ball mill for 10 minutes, wherein the revolution is 60-100r / min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com