Injection molding grade polypropylene wood-plastic micro-foaming composite material and preparation method thereof

A wood-plastic composite material and composite material technology are applied in the field of injection-molded polypropylene wood-plastic micro-foaming composite material and its preparation, which can solve the problem of poor compatibility between polypropylene and wood powder, low melt strength, and improve the dispersion of wood powder. and other problems, to achieve the effect of low cost, improved mechanical properties, and enhanced interfacial bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

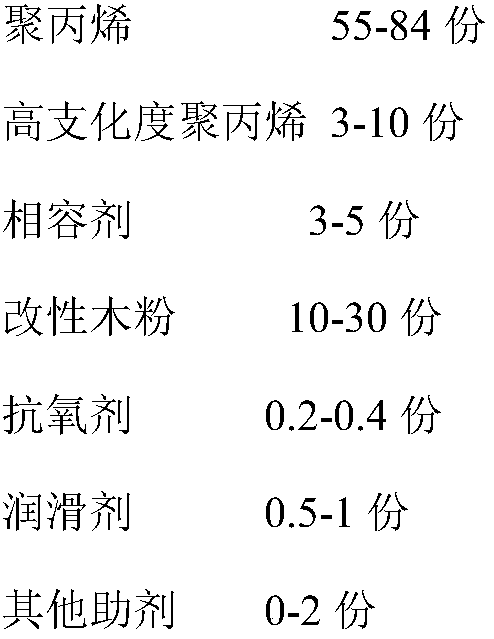

[0030] The injection-grade polypropylene wood-plastic micro-foaming composite material in this embodiment is composed of the following raw materials according to weight percentage:

[0031] Polypropylene Wood Plastic Composite 98%

[0032] Sodium bicarbonate chemical foaming agent coated with LDPE 2%

[0033] The polypropylene wood-plastic composite material described therein consists of the following raw materials in parts by weight:

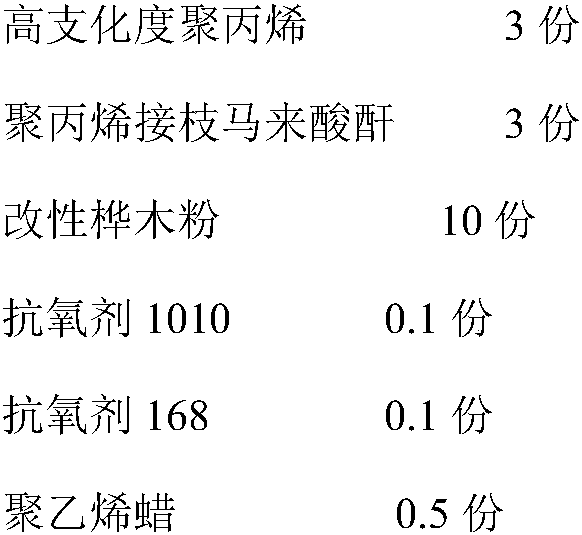

[0034]

[0035]

[0036] Concrete preparation method comprises the following steps:

[0037] (1) Weigh 96 parts of birch powder and 4 parts of dodecyltrimethoxysilane coupling agent into 100mL ethanol:water solution with a volume of 90:10, stir at room temperature for 10min, heat up to 50°C and stir for 24h, centrifuge Separation, washing with deionized water for 3 times, vacuum drying the centrifuged product at 50°C for 24 hours, grinding the dried product, and finally obtaining modified birch powder;

[0038] (2) Take by weighing 10 ...

Embodiment 2

[0041] The injection-grade polypropylene wood-plastic micro-foaming composite material in this embodiment is composed of the following raw materials according to weight percentage:

[0042] Polypropylene Wood Plastic Composite 97%

[0043] Sodium bicarbonate coated chemical blowing agent 3% by LDPE

[0044] The polypropylene wood-plastic composite material described therein consists of the following raw materials in parts by weight:

[0045]

[0046] Concrete preparation method comprises the following steps:

[0047] (1) Weigh 90 parts of poplar wood powder and 10 parts of hexadecyltrimethoxysilane coupling agent into 100 mL of ethanol: water solution with a volume of 90:10, stir at room temperature for 20 min, then raise the temperature to 55 ° C and stir for 36 h , centrifuged, washed 4 times with deionized water, vacuum-dried the centrifuged product at 60°C for 36 hours, and ground the dried product to finally obtain modified poplar wood powder;

[0048](2) Take by we...

Embodiment 3

[0051] The injection-grade polypropylene wood-plastic micro-foaming composite material in this embodiment is composed of the following raw materials according to weight percentage:

[0052] Polypropylene Wood Plastic Composite 97%

[0053] Sodium bicarbonate coated chemical blowing agent 3% by LDPE

[0054] The polypropylene wood-plastic composite material described therein consists of the following raw materials in parts by weight:

[0055]

[0056] Concrete preparation method comprises the following steps:

[0057] (1) Weigh 93 parts of poplar wood powder and 7 parts of hexadecyltrimethoxysilane coupling agent into 100 mL of ethanol:water solution with a volume of 90:10, stir at room temperature for 30 minutes, heat up to 60°C and stir for 48 hours at a constant temperature, Centrifuge, wash 5 times with deionized water, vacuum dry the centrifuged product at 80°C for 24-48 hours, grind the dried product, and finally obtain modified poplar wood powder;

[0058] (2) Take...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com