Preparation of supported palladium catalyst Fe3O4/SiO2/Pd and application of supported palladium catalyst Fe3O4/SiO2/Pd in Suzuki reaction

A technology of supported palladium and catalyst, which is applied in the field of preparation of supported palladium catalyst Fe3O4/SiO2/Pd, can solve the problems of poor controllability of synthesis process conditions, poor experimental stability, and easy aggregation of particles, so as to be beneficial to environmental protection, The effect of easy separation and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Fe 3 o 4 / SiO 2 / Preparation of Pd

[0034] (1) Preparation of simulated biological beneficiation tailing liquid: use Thiobacillus ferrooxidans to prepare the tailing liquid produced in simulated biological beneficiation and coal biodesulfurization. g / L, potassium chloride: 0.1g / L, dipotassium hydrogen phosphate: 0.5g / L, magnesium sulfate heptahydrate: 0.5g / L, calcium nitrate: 0.01g / L; b, inoculate Thiobacillus ferrooxidans Add 9.0g / 200mL ferrous sulfate heptahydrate culture solution to the bacterial culture solution, put the culture solution in a Erlenmeyer flask, wrap the mouth of the bottle with two layers of medical gauze, and place it on a constant temperature shaker at 28-30°C for shaking culture , after one week of bacterial culture, more than 95% of the Fe in the culture solution 2+ Oxidized by bacteria to Fe 3+ , the number of bacteria reaches 6×10 7 ~8×10 7 / mL, the main components of the solution are basically the same as the treated biom...

Embodiment 2

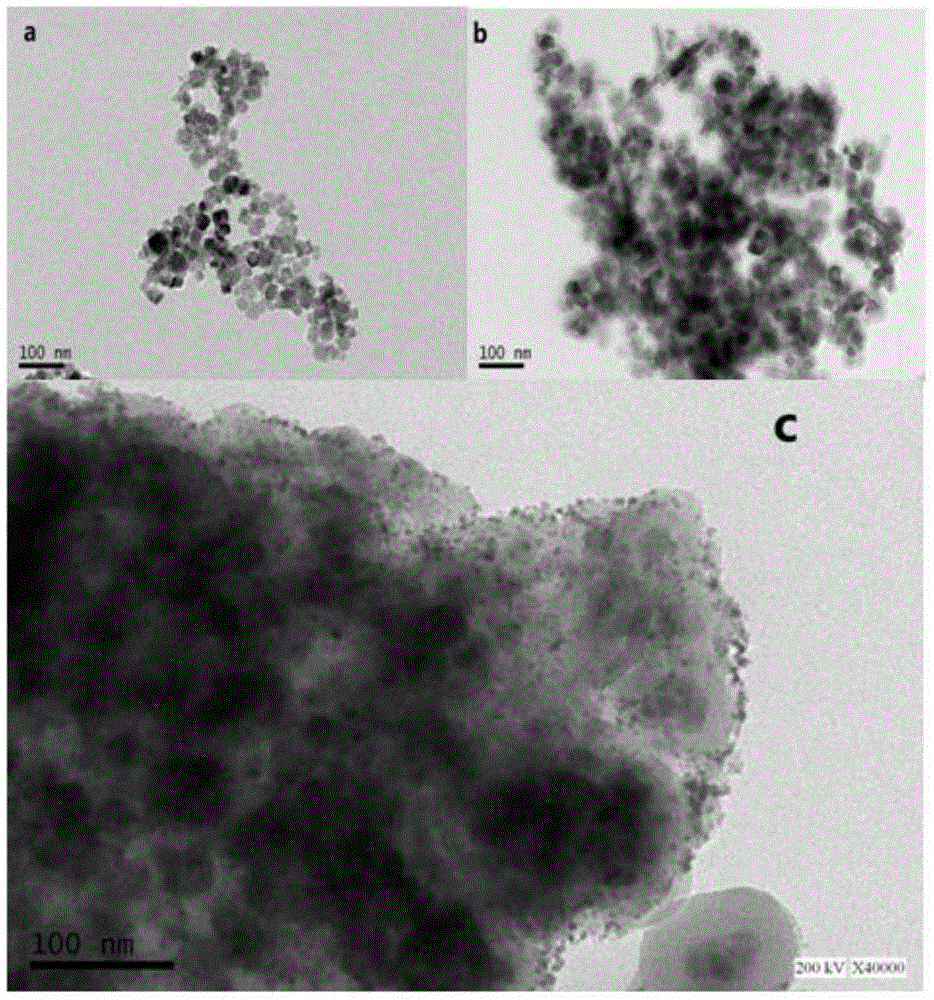

[0041] Example 2: figure 1 Among them, a and b are transmission electron microscopes of Fe3O4 and SiO2-coated Fe3O4 magnetic microspheres, respectively. Depend on figure 1 a It can be seen that the prepared magnetic nanometer has a regular octahedral structure. The dispersion is uniform, and the particle size is about 30 nanometers. figure 1 In b, silicon dioxide has been coated on ferric oxide nanoparticles, and the core-shell structure is more obvious. During the coating process, some of the silica coated a single nanoparticle, and some coated multiple nanoparticles, and the shape of the coating changed with the Fe 3 o 4 changes in shape. The monodispersity of the magnetic composite microspheres is better. The particle diameter of the silicon dioxide magnetic composite microsphere is 35-50 nm. From figure 1 c It can be seen that the fine particles are evenly coated on the surface of the magnetic composite microspheres. It can be seen from the literature that the part...

Embodiment 3

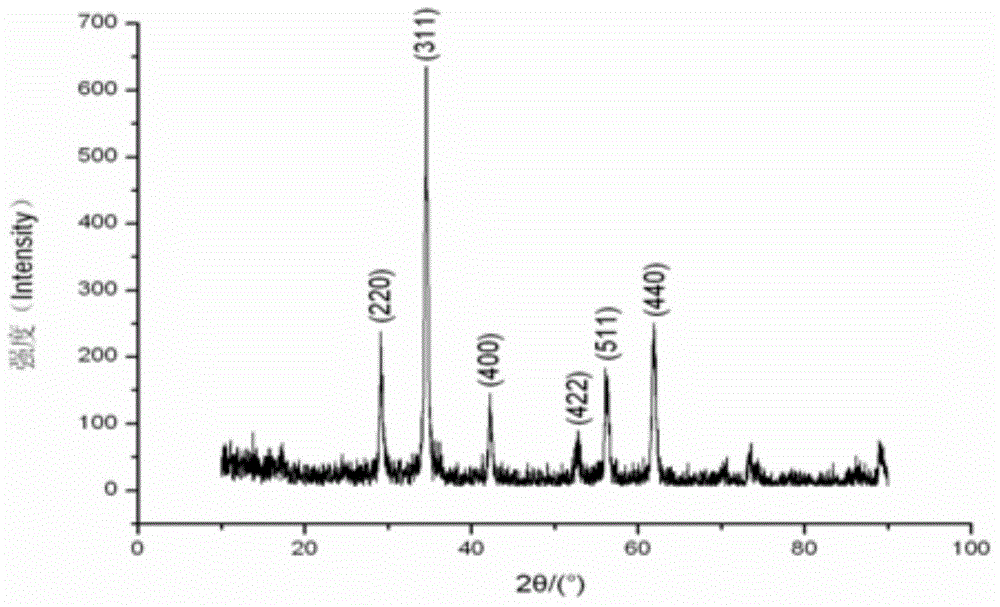

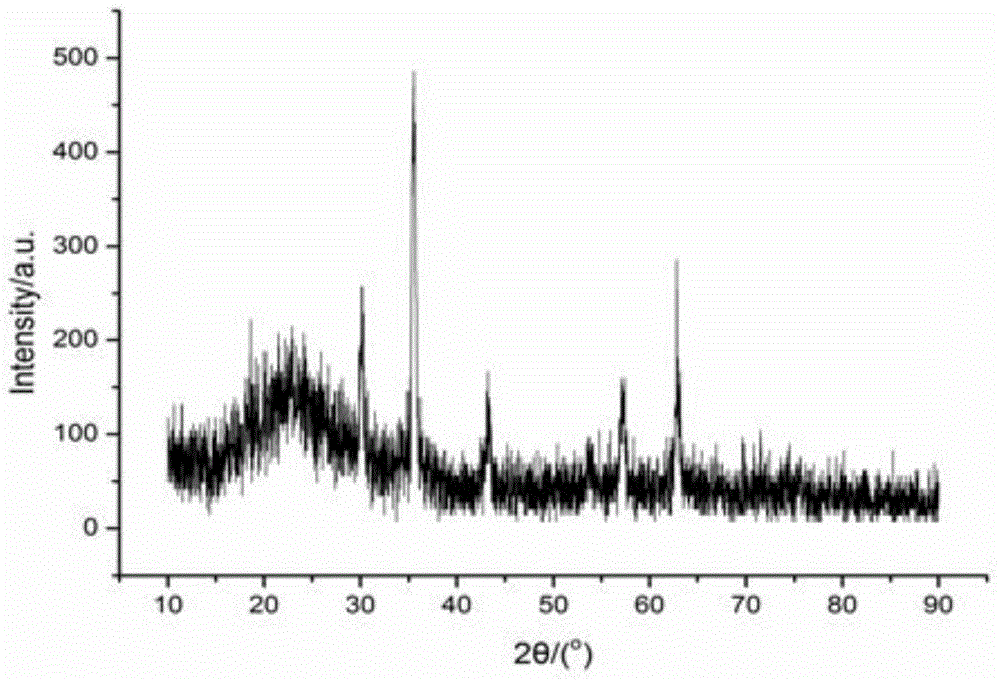

[0042] Example 3: figure 2 , 3 It is the X-ray diffraction pattern of magnetic iron ferric oxide nanoparticle powder and silicon dioxide magnetic nanoparticle. According to the standard spectrum data (JCPDS Card No.85-691), ferric oxide nanoparticles ( figure 2 ) diffraction characteristic peaks correspond to the (220), (311), (400), (422), (511), (440) crystal planes of the crystal respectively, and it can be seen that the magnetic nanoparticles are spinel structures. In silica magnetic microspheres ( image 3 ) in the XRD spectrum, 2θ is around 25° and amorphous SiO appears 2 The characteristic diffraction peak and the crystal plane of the characteristic peak of ferric oxide are present, and the peak shape becomes wider, indicating that silicon dioxide is coated on the surface of ferric oxide, and the coating state is amorphous. Figure 4 It is the XRD spectrum of palladium-coated magnetic microspheres. According to the standard spectrum, Fe 3 o 4 There are six char...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com