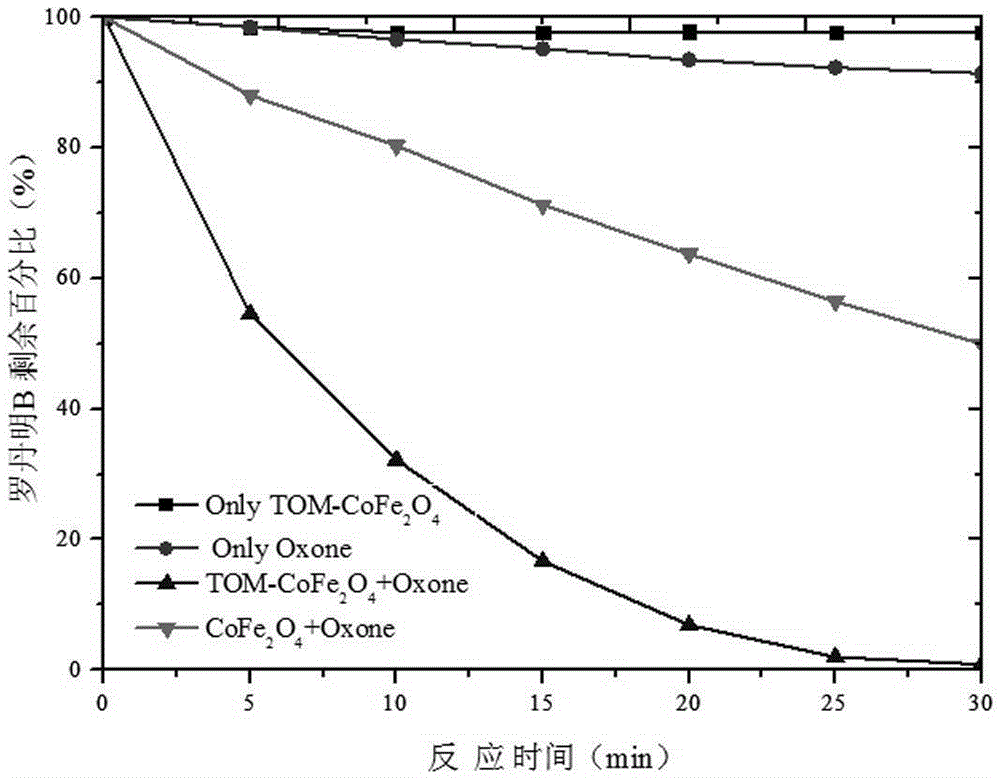

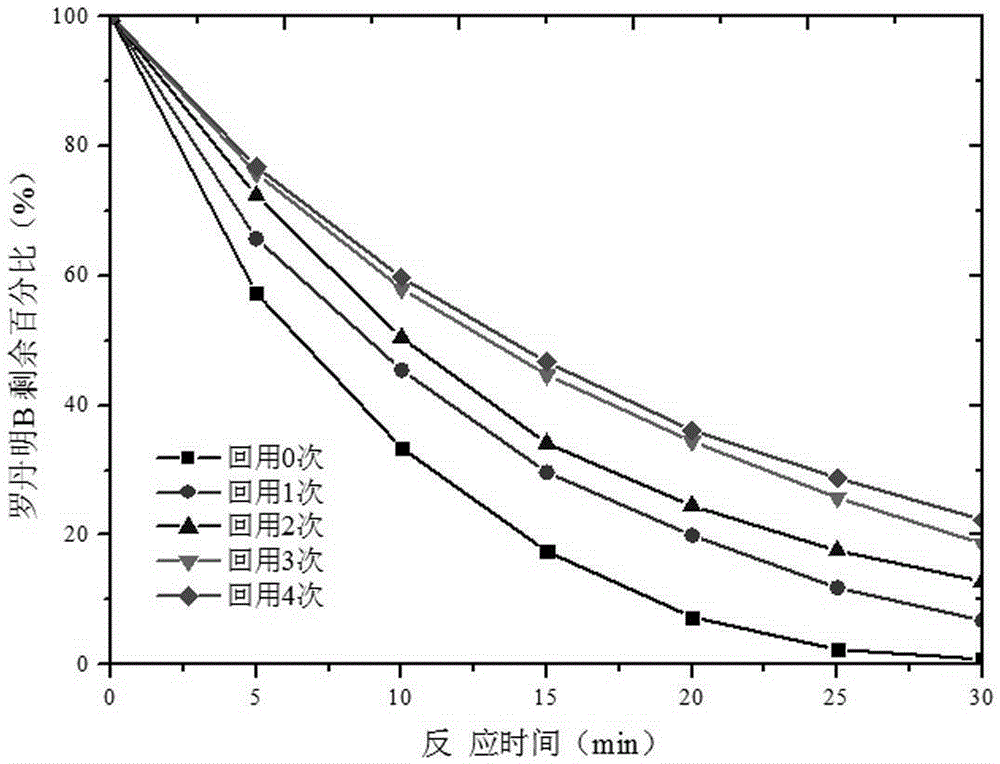

Method for processing dye waste water based on activation of peroxymonosufate by three-dimensional ordered mesoporous CoFe2O4

A technology for activating persulfate and dye wastewater, applied in chemical instruments and methods, oxidized water/sewage treatment, magnetic field/electric field water/sewage treatment, etc., can solve catalyst recovery difficulties, environmental secondary pollution, spinel type Low catalytic performance of cobalt ferrite and other problems, to achieve the effect of simple operation, pollution reduction and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0038] In this embodiment, a method for treating dye wastewater based on three-dimensional magnetically ordered mesoporous cobalt ferrite activated persulfate is carried out in the following steps:

[0039] 1. Preparation of three-dimensional magnetically ordered mesoporous cobalt ferrite (Three-dimensional ordered mesoporous CoFe 2 o 4 ,TOM-CoFe 2 o 4 );

[0040] The KIT-6 template, Co(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O is successively placed in a mortar containing n-hexane and fully ground, and the fully ground material is transferred to a round-bottomed flask filled with n-hexane, and refluxed and stirred for 12 hours under the condition of a 70°C water bath;

[0041] step one KIT-6 template, Co(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 The molar ratio of O is 8:1:2;

[0042] step one KIT-6 template, Co(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O is placed in a mortar containing n-hexane in turn and fully ground, and the volume requirement of n-hexane is tha...

specific Embodiment approach 2

[0059] The difference between this embodiment and the first embodiment is that the concentration of the target pollutant Rhodamine B in the second step is 50 mg / L-100 mg / L, and other steps and parameters are the same as the first embodiment.

specific Embodiment approach 3

[0060] The difference between this embodiment and specific embodiments 1 to 2 is that the concentration of the target pollutant Rhodamine B in step 2 is 100 mg / L-200 mg / L, and other steps and parameters are the same as those of specific embodiments 1 to 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com