Composite conducting microball and its preparing method

A composite conductive and microsphere technology, applied in the direction of microsphere preparation, microcapsule preparation, etc., can solve the problems of poor conductivity, poor conductivity, and low cost of metal oxides, and achieve simple and easy preparation process and good perception ability , can be designed strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

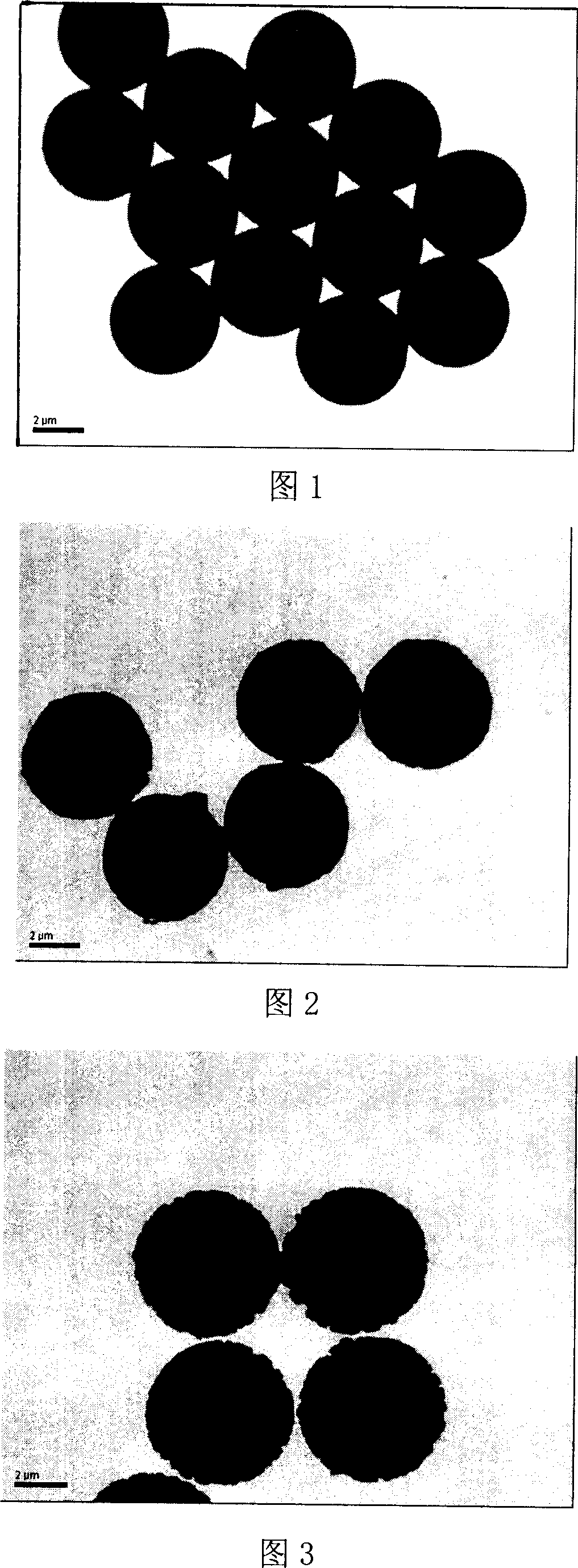

[0017] Example 1: Preparation of nickel-phosphorus alloy polymer conductive microspheres

[0018] Weigh 3.0g of polymer microspheres and add water to fully ultrasonically disperse them evenly, then soak them in alkaline solution, wash them with acid solution, and then thoroughly wash them with pure water to make a 10% aqueous solution, put them into a 1L three-necked flask, and heat to 60 ℃, add 100m10.1% PdCl2 aqueous solution 200 / rpm and stir for 20 minutes, then filter with suction and wash with pure water until the effluent is clean.

[0019] Disperse the above-washed polymer microspheres with 200ml of pure water and add them to a 1L three-necked flask, heat to 60°C, add 100ml, 1.0% sodium hypophosphite aqueous solution under stirring at 200 rpm, react for 15 minutes, and then Suction filter and wash with water.

[0020] Fully disperse the above polymer microspheres activated with palladium into the following chemical plating solution, put them into a 10L reactor, and rea...

Embodiment 2

[0030] Example 2: Preparation of nickel-boron alloy polymer conductive microspheres

[0031] Weigh 3.0g of polymer microspheres and add water to fully ultrasonically disperse them evenly, then soak them in lye, wash them with acid solution, wash them thoroughly with pure water, and make a 10% aqueous solution, put them into a 1L three-necked flask, and heat to 60 ℃, add 100m, 10.1% colloidal palladium solution, stir and react at 200 / rpm for 20 minutes, and then wash with pure water until clean.

[0032] Disperse the above-washed polymer microspheres with 200ml of pure water and add them to a 1L three-neck flask, heat to 60°C, add 100ml of dilute HCl (1:9) solution under stirring at 200 rpm and stir for 1 minute, then Suction filter and wash with pure water.

[0033] Fully disperse the above polymer microspheres activated with palladium into the following electroless nickel plating solution, put them into a 10L reactor, and react for 30-120 minutes under stirring at 300 rpm, t...

Embodiment 3

[0043] Example 3: Preparation of gold-coated polymer conductive microspheres

[0044] Weigh 3.0g of polymer microspheres and add water to fully ultrasonically disperse them evenly, then soak them in lye, wash them thoroughly with pure water, and make a 10% aqueous solution, put them into a 1L three-necked flask, heat to 60°C, and add 100ml , 0.1% PdCl2 aqueous solution, stirred and reacted at 200 rpm for 20 minutes, then suction filtered and washed with pure water until the effluent was clean.

[0045] Disperse the above-washed polymer microspheres with 200ml of pure water and add them to a 1L three-necked flask, heat to 60°C, add 100ml of 1.0% sodium hypophosphite aqueous solution to react for 15 minutes while stirring at 200 rpm, and then pump Filter and wash with water.

[0046] Fully disperse the above polymer microspheres activated with palladium into the following chemical deposition gold plating solution, put them into a 10L reactor, stir and react at 300 rpm for 30-12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com